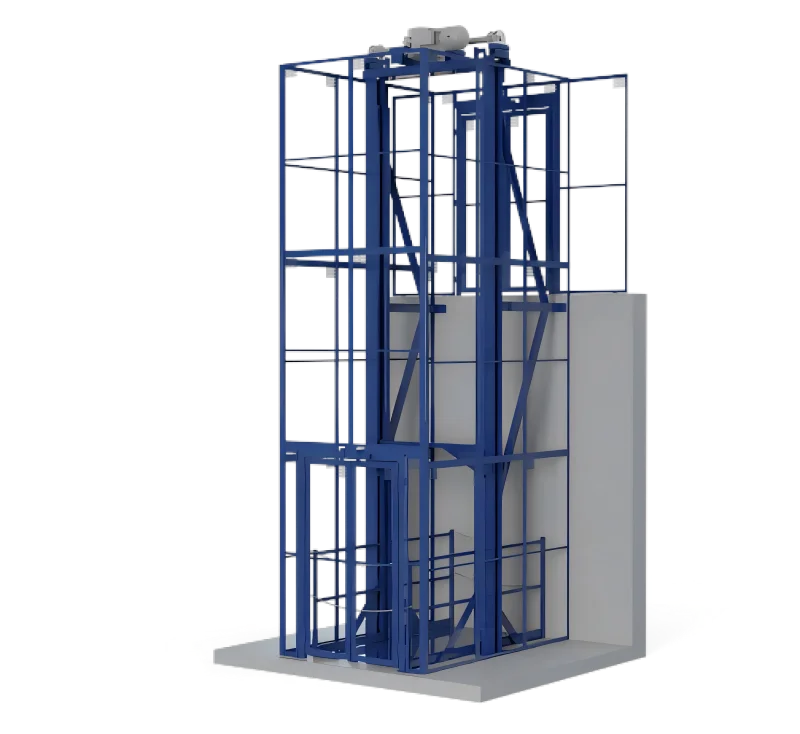

VRC 스 트래들 리프트

VRC 스 트래들 리프트는 두 개의 가이드 컬럼 사이에 캐리지가 위치하여 양쪽 컬럼을 따라 하중을 효과적으로 고르게 분산하는 것이 특징입니다. 캔틸레버 구성에 비해 이 설계는 적재 용량이 더 크고 캐리지 플랫폼이 더 넓으며 적재 및 하역 시 발생하는 더 큰 전복력도 견딜 수 있습니다. 스 트래들 레이아웃은 C- 로딩(정면에서 적재 및 하역)과 Z- 로딩(반대쪽에서 적재 및 하역)을 모두 지원하므로 공간 제약이 없고 적재 높이에 제한이 없는 애플리케이션에 이상적입니다.

자세히 알아보기 팀에 문의

사양

최대 부하 용량

- 범위: 2~10미터톤(모델에 따라 다름)

- 핵심 포인트: 듀얼 컬럼 스트래들 구성으로 무게를 고르게 분산하여 다음을 제공합니다. 30-50% 더 높은 용량 캔틸레버 리프트보다 높습니다.

플랫폼 크기

- 일반적인 크기: 1.5~3m(폭) × 2~4m(깊이)(사용자 지정 가능)

- 요점: 더 큰 플랫폼은 대형 하중을 수용하고 다음을 허용합니다. 직접 지게차 액세스 안정성 위험 없이.

최대 리프트 높이

- 범위: 6-20m(수직 이동, 중간 층 제한 없음)

- 핵심 포인트: 이중 기둥 강성으로 다음과 같은 안정성을 보장합니다. 고고도 자재 취급.

전복 모멘트 저항

- 임계값: ≥5kN-m(동적 부하 저항)

- 핵심 포인트: 견고한 스 트래들 디자인 적재/하역 중 횡력캔틸레버 리프트(일반적으로 ≤2kN-m)를 능가합니다.

로딩/언로딩 모드

- 지원 모드:

- "C형"(전면 로딩)

- "Z형"(반대쪽에서 스루 로딩)

- 핵심 포인트: 사용 양방향 워크플로 창고 또는 생산 라인의 경우 다음과 같은 방법으로 공간 효율성을 개선합니다. 40%+.

특징

🔹 비용 효율성을 위한 최소한의 인클로저 설계: 최소한의 인클로저 구조로 안전성을 보장하는 동시에 비용 효율성을 최적화합니다.

🔹 적재 및 하역 옵션: 다양한 물류 워크플로우를 수용할 수 있도록 C-로딩(같은 쪽 입출고) 및 Z-로딩(반대쪽 입출고)을 지원합니다.

🔹 다양한 화물 크기에 맞게 조정 가능: 유연한 디자인으로 다양한 크기와 무게의 화물을 쉽게 처리할 수 있습니다.

🔹 효율적인 수직 운송: 여러 층 간에 상품을 빠르고 안전하게 이동하여 운영 효율성을 높입니다.

여기에서 문의

옵션 및 액세서리

🔹로딩/언로딩 보조 도구

- 셀프 레벨링 플랫폼: 유압식/전기식 기울기 보정(±2°)으로 바닥을 매끄럽게 정렬합니다.

- 확장형 브리지 플레이트: 0.5~1.5m 확장하여 층 사이의 간격을 메울 수 있습니다.

🔹안전 강화

- 적외선 라이트 커튼/안전 모서리: 비상 정지 기능이 있는 장애물 감지(ANSI/ASME B20.1 준수).

- 기계식 추락 방지 잠금 장치: 전원 손실 시 자동 잠금 기능으로 플랫폼 하강을 방지합니다.

🔹환경 적응

- 결로 방지 히터: 냉장실(-30°C)에 얼음이 쌓이는 것을 방지합니다.

- 부식 방지 코팅: 열악한 환경을 위한 아연 도금/에폭시 코팅(C5-M 등급).

🔹자동화 통합

- RFID/바코드 스캐너: 무인 물류를 위한 화물 자동 식별.

- PLC + 터치스크린 제어: 다층 사전 설정, ERP/MES 호환성.

🔹플랫폼 사용자 지정

- 미끄럼 방지 표면: 다이아몬드 패턴 강철(마찰 계수 ≥0.6).

- 접이식/모듈식 가드레일: 다양한 하중 크기에 맞게 조정 가능.

🔹에너지 회수

회생 제동: 중력 에너지를 전기로 변환하여 15-20%의 전력을 절약합니다.

| 산업 | 주요 액세서리 | 목적 |

|---|---|---|

| 식품/제약 | 스테인리스 스틸(304/316L), 식품 등급 그리스 | FDA 규정 준수, 세척 저항성. |

| 자동차 | 견고한 롤러 트랙(1톤/바퀴) | AGV 도킹 인터페이스, 내충격성. |

| 항공우주 | 탄소 섬유 플랫폼 + ESD 코팅 | 30% 무게 감소, 정전기 보호. |

| 웨어하우징 | 연동 도어 시스템 | 작동 중 액세스를 방지합니다. |

예측 유지보수 키트: 실시간 마모 모니터링을 위한 진동/온도 센서.

모듈식 확장: 추가 기능(예: 조명, 계량 시스템)을 위한 개조 지원.

이중 기둥 설계로 흔들림 없이 4톤의 하중을 처리할 수 있고, Z-Type 적재 방식으로 이송 시간을 단축하는 등 Gradin VRC 스 트래들 리프트는 창고에 혁신을 가져왔습니다. RFID 및 셀프 레벨링 옵션이 추가되어 효율성이 40%까지 향상되었습니다. 유압식 리프트에 비해 유지보수가 최소화되고 OSHA를 준수하는 것도 큰 장점입니다. 무거운 하중을 위한 견고하고 공간 절약형 제품입니다. 산업용 수직 운송을 위한 최고의 투자!

업계의 자재 취급 장비

그라딘 상품 리프트는 완제품이나 재료 또는 장비가 담긴 팔레트 적재물을 메자닌 층이나 2층에서 위아래로 운반하는 데 사용할 수 있습니다. 리프트의 플랫폼은 스테인리스 스틸로 제작되어 규정을 준수하고 부식되지 않으며 세척이 가능합니다.

근골격계 부상을 염두에 두고 다음은 생산 공정 중 제조 및 엔지니어링 부문에서 흔히 발생하는 상황의 유용하지만 전부는 아닌 목록입니다:

- 몸통에서 멀리 떨어진 곳에서 하중을 반복적으로 조작합니다.

- 짐을 들어 올리기 위해 트렁크를 반복적으로 구부립니다.

- 파악하기 어려운 매우 큰 부하입니다.

- 어깨 높이 또는 바닥 높이에서 짐을 반복적으로 취급합니다.

- 몸통을 비틀어 들어 올리는 리프팅.

- 짐은 어수선하거나 위험한 지역을 통해 장거리로 운반해야 합니다.

수작업 취급 활동이 불리한 인체공학적 조건으로 인해 부상(특히 허리)의 위험이 있는 경우, 고용주는 부상 위험을 줄이거나 제거하기 위한 조치를 취해야 한다는 것이 기본 원칙입니다.

Gradin 물품 리프트는 표준 크기의 팔레트를 제조 현장에서 메자닌 또는 1층의 창고로 운반하도록 특별히 설계되었습니다. 표준 사양이 고객의 모든 요구 사항을 충족하지 못하는 경우, 고객과 협력하여 회사, 직원 및 제품에 완벽한 최종 솔루션을 제공하기 위해 맞춤형 구성도 전문으로 제공합니다.