방폭형 시저스 리프트 플랫폼

당사의 방폭형 시저스 리프트 플랫폼은 스파크, 전기 아크 또는 고온 가스로 인한 폭발을 방지하도록 설계된 특수 리프팅 장비입니다. 방폭 모터, 방폭 제어 시스템, 밀폐형 보호 설계를 사용하여 인화성 가스나 먼지를 외부 환경으로부터 효과적으로 차단하여 위험한 조건에서도 안전하게 작동할 수 있도록 보장합니다. 일반적으로 화학 공장, 석유 및 가스 산업, 탄광, 발전소, 창고 및 기타 위험 지역에서 사용되며 열악한 환경에서 상품을 안전하게 수직 운송할 수 있도록 보장합니다.

자세히 알아보기 팀에 문의

사양

| 매개변수 | 사양 |

|---|---|

| 모델 번호 | EP-SLP-XX(하중 용량 및 높이에 맞게 사용자 지정 가능) |

| 부하 용량 | 1,000~5,000kg(산업 요구 사항에 따라 조정 가능) |

| 리프팅 높이 | 3-15m(유압 구동 가위 메커니즘) |

| 플랫폼 크기 | 2,000×1,200mm(표준) / 최대 5,000×2,500mm까지 사용자 지정 가능 |

| 전원 소스 | 방폭형 모터(380V/50Hz) |

| 제어 시스템 | 비상 정지, 과부하 보호 및 기울기 방지 기능을 갖춘 방폭형 PLC |

| 작동 온도 | -20°C ~ +50°C(서리/내열성 유압 오일 사용) |

특징

🔹 방폭 설계: 방폭 모터, 방폭 제어 시스템, 밀폐형 보호 설계로 위험한 환경에서도 안전하게 작동할 수 있습니다.

🔹 높은 안전성: 인화성 가스나 먼지를 효과적으로 차단하여 스파크나 전기 아크가 폭발을 일으키는 것을 방지합니다.

🔹 방수 및 방진: 외부의 습기와 먼지가 장비에 유입되는 것을 방지하는 실링 시스템이 장착되어 있어 열악한 작업 환경에 적합합니다.

🔹 낮은 유지보수 비용: 간단한 구조로 유지보수가 용이하여 고장률을 낮추고 장기적인 운영 비용을 절감합니다.

여기에서 문의

옵션 및 액세서리

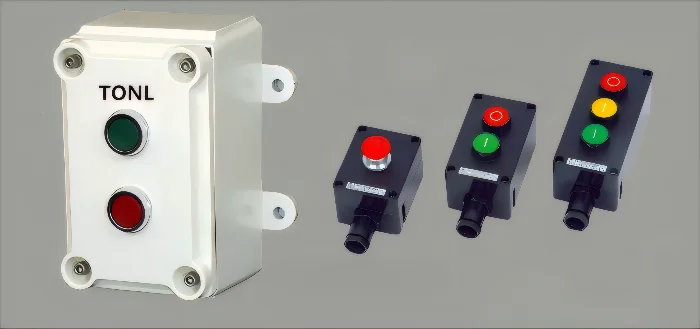

방폭 구성 요소

모터 및 제어:

인증된 방폭형 유압 동력 장치.

비상 정지 기능이 있는 Ex d/e 등급 제어 패널(IP65/IP66).

전기 시스템:

방폭 배선, 정션 박스 및 리미트 스위치.

본질 안전(IS) 리모컨 또는 펜던트 스테이션.

머티리얼 업그레이드:

열악한 환경을 위한 스테인리스 스틸 또는 부식 방지 코팅.

스파크 방지 플랫폼 바닥재(예: 알루미늄 또는 스파크 방지 복합재).

안전 및 운영 액세서리

안전 기능:

비상 하강 시스템(수동 또는 배터리 백업).

안전 레일, 발가락 보호대, 미끄럼 방지 표면.

과부하 보호 센서 및 연동 게이트.

추락 방지 고정 지점(OSHA/EN 준수).

운영 개선 사항:

확장된 작업 공간을 위한 플랫폼 확장 또는 접이식 섹션.

회전 턴테이블(360° 회전 옵션).

고르지 않은 표면을 위해 기울기 또는 수평 조절 잭을 조절할 수 있습니다.

설치 및 유지 관리

마운팅 키트:

앵커 볼트, 베이스 프레임 또는 피트 장착 시스템.

유지 관리 도구:

윤활 키트, 유압유 저장소 및 서비스 매뉴얼.

어두운 공간에서 유지보수를 위한 방폭 조명.

모니터링 시스템:

상태 모니터링 센서(진동, 온도).

예측적 유지보수를 위한 무선 진단.

수출 관련 요구 사항

문서화:

다국어 매뉴얼(영어, 스페인어, 프랑스어 등).

CE/UKCA 마크, 테스트 인증서 및 EX 증명 서류.

포장:

녹슬지 않는 VCI 포장으로 내후성 상자.

목재 재료에 대한 ISPM 15 준수.

사용자 지정:

대상 국가에 대한 전압/주파수 조정.

현지화된 라벨 및 위험 경고(예: OSHA, ISO 기호).

선택적 애드온

환경 적응:

극한의 온도(-20°C ~ +50°C)를 위한 HVAC 시스템.

방진 또는 방수 인클로저(IP67).

고급 제어:

HMI 터치스크린을 통한 PLC 자동화.

RFID 또는 생체 인식 액세스 제어.

조명:

방폭형 LED 작업등(플랫폼에 통합됨).

모든 산업과 모든 애플리케이션에 자재 취급 장비를 공급하는 것을 자랑스럽게 생각합니다.

업계의 자재 취급 장비

그라딘 상품 리프트는 완제품이나 재료 또는 장비가 담긴 팔레트 적재물을 메자닌 층이나 2층에서 위아래로 운반하는 데 사용할 수 있습니다. 리프트의 플랫폼은 스테인리스 스틸로 제작되어 규정을 준수하고 부식되지 않으며 세척이 가능합니다.

근골격계 부상을 염두에 두고 다음은 생산 공정 중 제조 및 엔지니어링 부문에서 흔히 발생하는 상황의 유용하지만 전부는 아닌 목록입니다:

- 몸통에서 멀리 떨어진 곳에서 하중을 반복적으로 조작합니다.

- 짐을 들어 올리기 위해 트렁크를 반복적으로 구부립니다.

- 파악하기 어려운 매우 큰 부하입니다.

- 어깨 높이 또는 바닥 높이에서 짐을 반복적으로 취급합니다.

- 몸통을 비틀어 들어 올리는 리프팅.

- 짐은 어수선하거나 위험한 지역을 통해 장거리로 운반해야 합니다.

수작업 취급 활동이 불리한 인체공학적 조건으로 인해 부상(특히 허리)의 위험이 있는 경우, 고용주는 부상 위험을 줄이거나 제거하기 위한 조치를 취해야 한다는 것이 기본 원칙입니다.

Gradin 물품 리프트는 표준 크기의 팔레트를 제조 현장에서 메자닌 또는 1층의 창고로 운반하도록 특별히 설계되었습니다. 표준 사양이 고객의 모든 요구 사항을 충족하지 못하는 경우, 고객과 협력하여 회사, 직원 및 제품에 완벽한 최종 솔루션을 제공하기 위해 맞춤형 구성도 전문으로 제공합니다.