27.4.2025 / 6분 읽기

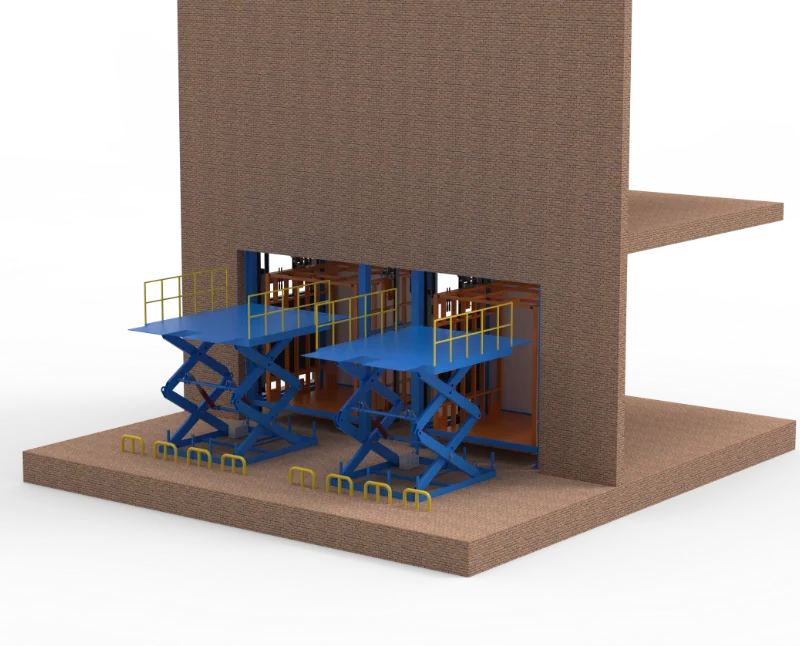

1톤 유압 적재 플랫폼 - 창고를 위한 높이 조절식 도크-투-리프트 솔루션

프로젝트 개요

1989년에 설립된 이 고객은 파워 스포츠 차량 제조 분야의 글로벌 리더입니다. 모든 지형용 차량, 모터사이클, 전기 스쿠터, 엔진에 주력하며 최첨단 연구 개발과 ISO 인증 제조 공정을 결합합니다. 다카르 랠리에서 검증된 모델을 포함하여 100여 개국의 레저용, 농업용, 군용 시장에 제품을 공급하고 있습니다. 유로 5/EPA 표준을 충족하는 혁신적인 엔진으로 유명하며 하이브리드 및 전기 솔루션을 통해 미래 모빌리티를 주도하고 있습니다.

리프팅 기계와 트럭 간의 원활한 전환을 위한 완벽한 솔루션! 1톤의 견고한 적재 용량과 0.7~3미터까지 높이를 조절할 수 있는 이 다목적 플랫폼은 원활한 적재 및 하역 작업을 보장합니다. 유압식 플립 보드와 수동식 플립 보드로 도크와 리프트를 쉽게 연결할 수 있으며, 안전 가드레일이 작업자의 추락을 방지합니다. 효율성을 위해 설계된 이 제품은 이동성과 안정성을 모두 갖추고 있어 안전하고 빠르고 효과적인 창고 및 물류 작업에 이상적인 도구입니다.

도전 과제

높이 일치: 트럭 높이 편차가 큰 경우(0~7.5m) 원활한 도킹을 위해 정밀한 플랫폼 조정이 필요합니다.

운영 복잡성: 잦은 플립 플레이트 작동(차량당 2회)은 시간과 기계적 마모를 증가시킵니다.

안전 위험: 수동 차량 취급은 추락 위험을 초래할 수 있으므로 완전한 간격 보호가 필요합니다.

효율성 병목 현상: 수직 컨베이어는 트럭 적재가 완료될 때까지 기다려야 하므로 물류 주기가 지연됩니다.

솔루션

유압식 높이 조절:

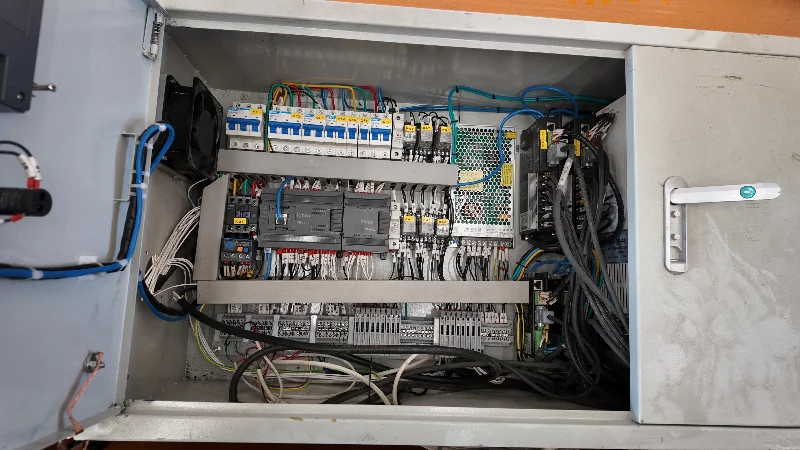

인코더 기반 높이 맞춤 설정이 가능한 유압식 리프팅 시스템(0.7~3m 범위)으로 트럭 베드에 정밀하게 정렬할 수 있습니다.

모듈형 플립 플레이트:

컨베이어 도킹을 위한 자동 유압 플립 플레이트(폭 3m) + 트럭 적응성을 위한 수동 플립 플레이트(2×1m×1m), 플립 동작을 최소화합니다.

포괄적인 안전:

미끄럼 방지 표면, 가드레일, 접근 사다리는 플랫폼 운영 중 작업자의 안전을 보장합니다.

워크플로 간소화:

플랫폼은 임시 버퍼 구역 역할을 하여 수직 컨베이어가 재로딩을 위해 즉시 돌아와 처리량을 높일 수 있도록 합니다.

장점

- 효율성 향상: 반복적인 뒤집기를 제거하여 로딩 시간을 20% 단축하고 연속 작업을 가능하게 합니다.

- 향상된 안전성: 가드레일 및 낙하 방지 설계는 산업 안전 표준에 부합합니다.

- 광범위한 호환성: 적재함 높이가 0~7.5m인 트럭과 다양한 화물 시나리오에 맞게 조정할 수 있습니다.

- 내구성 및 비용 효율성: 유압식 시스템으로 기계식 플립 메커니즘 대비 낮은 유지보수 비용으로 안정성을 보장합니다.

- 인간과 기계의 시너지 효과: 플랫폼에서의 안전한 수동 작업은 반자율 물류를 위해 자동화된 수직 컨베이어를 보완합니다.