8.25.2025 / 4-minute read

10톤 체인 터닝 롤 - 90/180° 정밀 뒤집기

프로젝트 개요

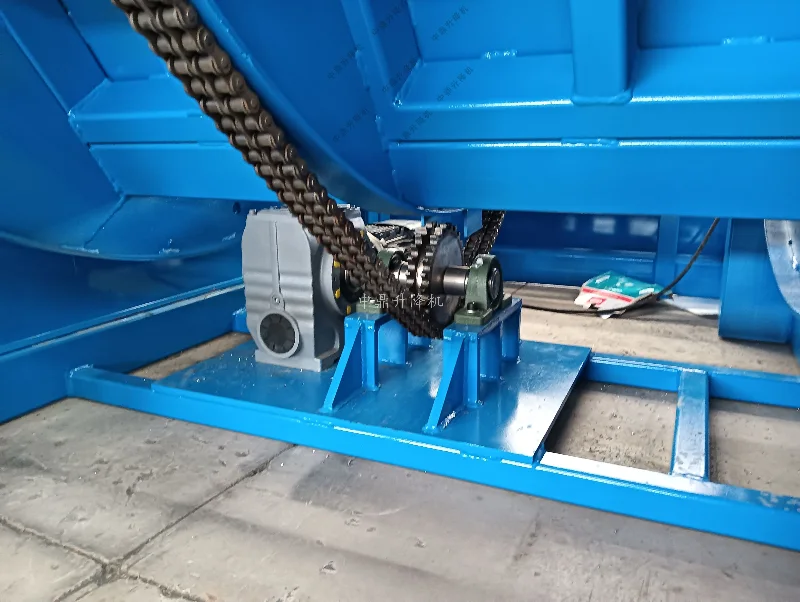

The 90-degree mechanical gear flipping machine, also known as a chain flipping platform, is a specialized equipment designed for lifting and flipping heavy-duty workpieces such as molds, castings, and mechanical components.

Utilizing a high-strength chain transmission system, it ensures precise and stable handling of loads up to 10 tons. With support for electric, hydraulic, or pneumatic drive systems, this device offers flexibility and reliability for various industrial applications, including manufacturing, maintenance workshops, and logistics.

기본 매개변수

| 항목 | 사양 |

|---|---|

| 최대 부하 용량 | 10톤 |

| Flipping Angle Range | 0-90° or 0-180° (user-selectable) |

| Drive Options | Electric, Hydraulic, or Pneumatic |

| 안전 기능 | Limit switches, overload protection, emergency stop buttons |

| Additional Features | Buffer devices, stabilization systems, modular design |

도전 과제

Handling heavy and bulky workpieces traditionally requires multiple pieces of equipment or manual labor, leading to inefficiencies, safety risks, and potential damage to materials.

Conventional methods often lack precision in angle control, stability during operation, and adaptability to diverse industrial environments.