9.8.2025 / 6분 읽기

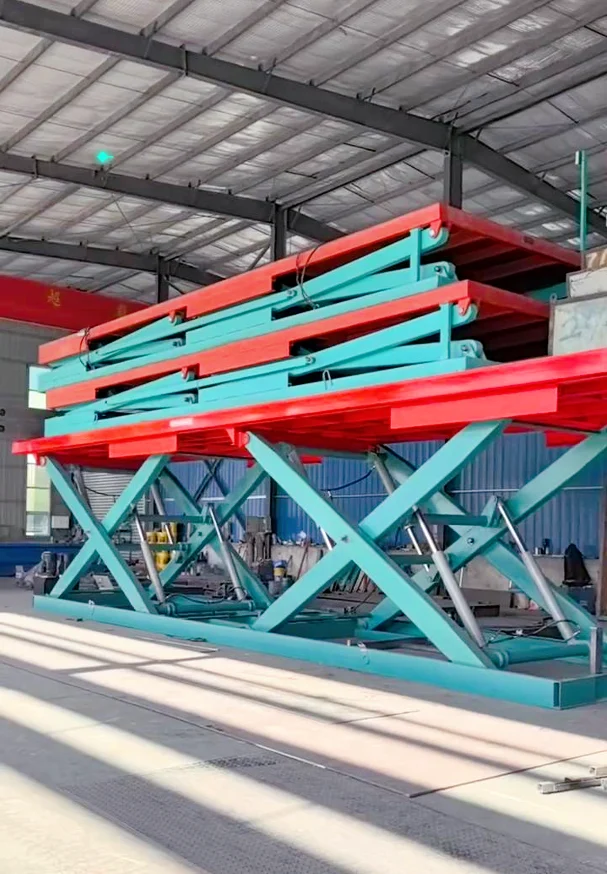

자동차 제조 중장비 층간 운송 솔루션 - 가이드 레일 이송 차량 리프터

기본 매개변수

| 매개변수 | 값/설명 |

|---|---|

| 리프팅 메커니즘 | 듀얼 시저, 동기식 유압 리프트 |

| 정격 부하 용량 | 사용자 지정 가능(보통 10~50톤) |

| 최대. 리프팅 높이 | 사용자 지정 가능(보통 1~5미터) |

| 플랫폼 크기 | 사용자 지정(전송 차량 트랙 게이지와 일치) |

| 레일 구성 | 작업장 트랙과 정렬된 플랫폼의 고정 레일 |

| 드라이브 시스템 | 유압식(고강도 정밀 실린더) |

| 제어 모드 | 자동/수동, 비상 정지 기능 |

| 표면 처리 | 고품질 베이킹 페인트, 녹 방지 및 부식 방지 |

| 주요 자료 | 고강도 망간강 |

작동 방식

장비는 구덩이에 설치되며 플랫폼은 공장 바닥과 같은 높이에 있습니다.

자동차 부품이나 차체를 적재한 전기 이송 차량이 플랫폼 위로 주행하면(통합 레일에 의해 정밀하게 안내됨) 정밀 유압 실린더에 의해 듀얼 시저 메커니즘이 동시에 작동하여 플랫폼과 적재물을 목표 높이까지 안정적으로 들어 올립니다.

도착하면 이송 차량이 레일을 따라 이동하여 층간 자재 이송을 완료할 수 있습니다.

전체 프로세스는 동기화 및 위치 정확도를 보장하는 지능형 제어 시스템으로 관리됩니다.

도전 과제

- 효율성 병목 현상: 엘리베이터나 경사로와 같은 기존 방식은 비효율적이며 사이클 시간 수요를 충족할 수 없습니다.

- 안전 위험: 무거운 구성품(예: 차체, 섀시)은 들어올리는 동안 이동하거나 떨어질 위험이 있습니다.

- 공간 제약: 소중한 바닥 공간은 고정 경사로가 차지하고 있습니다.

- 도킹 정확도: 차량 도킹 시 걸림이나 충격을 피하기 위해 높은 정밀도가 필요합니다.

- 유지 관리 비용: 장비는 고주파, 고부하 작동, 까다로운 내구성 및 유지보수 용이성을 견뎌야 합니다.

솔루션

- 효율적인 원활한 전송: 정밀한 레일 정렬로 빠른 드라이브 온/드라이브 오프가 가능하여 이송 시간을 대폭 단축합니다.

- 높은 부하 용량 및 안정성: 이중 시저 구조와 망간강으로 무거운 하중에서도 안정적인 작동과 긴 사용 수명을 보장합니다.

- 안전 및 신뢰성: 수입 씰링 링으로 누수 방지, 전원 차단 보호, 비상 정지 버튼, 낙하 방지 조치 등의 기능으로 종합적인 안전성을 보장합니다.

- 공간 최적화: 피트 장착형 설계로 귀중한 바닥 공간을 절약하여 깔끔하고 효율적인 작업장 레이아웃을 유지합니다.

- 내구성 있는 구조: 고품질 페인트와 망간강으로 기름과 부식을 방지하고 유지보수 빈도를 줄입니다.