9.3.2025 / 5분 읽기

가위형 316L 스테인리스 스틸 수중 리프팅 플랫폼

개요

암석 모델과 실험 장비를 설치하는 데 사용되는 이 플랫폼은 다양한 수심 조건에서 테스트 요구 사항을 시뮬레이션하기 위해 높이가 올라갑니다.

기본 매개변수

| 제품 모델 | SJG11-5.0 |

|---|---|

| 리프팅 플랫폼 크기 | D = 10000mm |

| 구조 유형 | 이중 스팬 단일 레이어 |

| 도킹 스테이션 | 2/2 |

| 스트로크 범위 | ≥ 5000mm 이상(1350-6500) |

| 정격 부하 | 11000kg |

| 장비 무게 | 약 32톤 |

| 장비 높이 | 1350mm(돌출 프레임 포함) |

| 리프팅 속도 | 0.4m/분 |

| 설치 방법 | 임베디드 파운데이션 설치 |

요구 사항

구조 및 재질

- 유압 구동 시스템이중 경간 단일 레이어 구조입니다.

- 316L 스테인리스 스틸 소재직경 10미터(현장 조건에 따라 조정될 수 있음).

- 리프팅 스트로크 ≥ 5.3미터 이상, 정격 하중 11톤 이상.

제어 및 모니터링

- 다음을 갖추고 있습니다. 현장 및 원격 제어 기능.

- 리프팅 플랫폼 제어 캐비닛에는 다음이 포함되어야 합니다. 제습 및 염분 방지 제어 장치.

- 설정 수중 풀 와이어 센서 (최소 2개)를 사용하여 위치 정확도 오차가 ±5mm 이하인 리프팅 높이를 모니터링합니다.

안전 보호

- 종합 안전 보호 기능비상 정지, 과부하 보호, 폭발 방지, 수동 하강, 위상 손실 보호.

- 기계식 추락 방지 장치유압식 텔레스코픽 지지대 사용, 수량 ≥ 4.

성능 요구 사항

- 리프팅 속도 ≥ 0.4m/min.

- 유압 제어에는 다음이 포함되어야 합니다. 체크 밸브.

- 유압 실린더는 다음을 활용합니다. 이중 레이어 씰링 링.

- 리프팅 플랫폼 표면은 1t/m² 이상의 하중을 균일하게 분산시켰습니다.

- 전체 평탄도 오류 ±5mm.

디자인 세부 정보

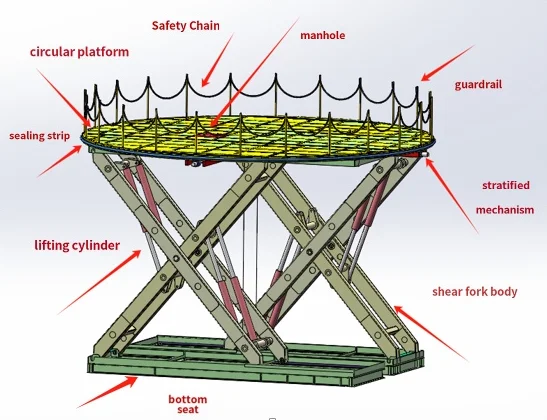

- 플랫폼의 엣지 기능 탈착식 가드레일 (총 21개) 1.5m 간격을 두고 316L 스테인리스 스틸로 제작된 중간 체인으로 연결됩니다.

- 표면 패널 두께 ≥ 6mm와 함께 타이 다운 링.

- 상단 표면은 다음과 같이 사전 설정되어 있습니다. 유지 보수 개방와 엣지 디자인 밀봉된 방수 스트립.

- 상단 표면에는 다음이 포함됩니다. 탈착식 타이 다운 링를 제거할 때 표면 높이를 초과하지 않아야 합니다.

솔루션

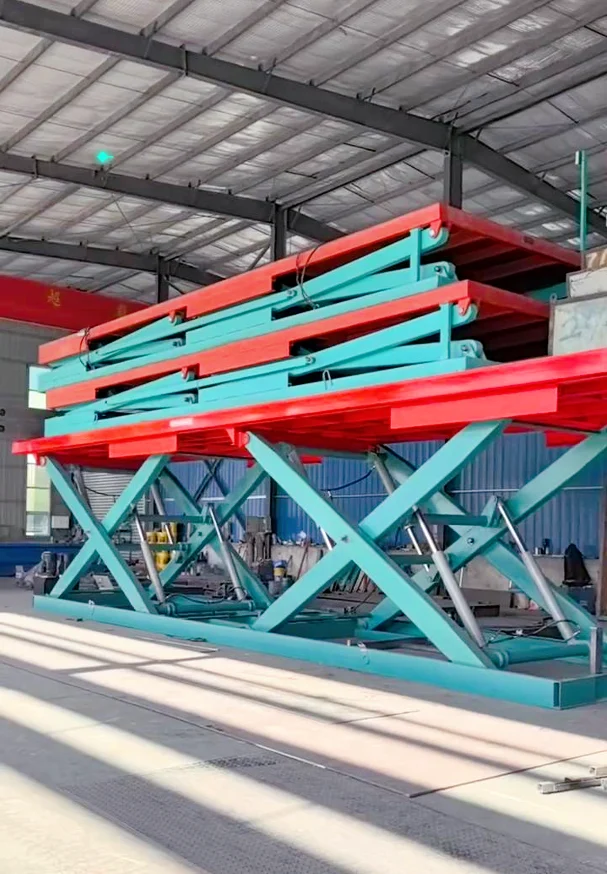

이 리프팅 플랫폼은 수중용으로 특별히 제작된 316L 스테인리스 스틸 소재의 가위형 디자인이 특징입니다. 가위형 기계 구조 덕분에 높은 안정성과 하중 용량을 제공합니다.

또한 이 플랫폼에는 터치스크린 제어 시스템이 장착되어 있어 사용자가 목표 높이를 설정하고 현재 높이를 실시간으로 표시할 수 있습니다.

솔루션

장비 구조

- 리프팅 플랫폼 본체

- 리프팅 플랫폼 액세서리

- 유압 스테이션

- 제어 시스템

유압 펌프 스테이션

리프팅 장비에 전원을 공급합니다.

제어 시스템

장비의 작동을 제어합니다.

리프팅 플랫폼 본체

- 기본

- 가위 메커니즘

- 리프팅 실린더

- 수평 조절 잠금 핀 메커니즘

- 안내 메커니즘

1. Base

장비를 고정하는 데 사용되는 베이스는 파운데이션에 고정됩니다. 장비가 조정되면 베이스가 파운데이션에 미리 내장된 강판에 용접되어 안정성을 보장합니다.

2. 가위 메커니즘

전원을 전송하고 장비에 대한 지원을 제공합니다.

3. 상단 프레임

프레임과 6mm 패널로 구성되어 하중을 견디는 기능을 합니다. 표면에는 필요에 따라 타이다운 링과 유지보수용 구멍이 있습니다.

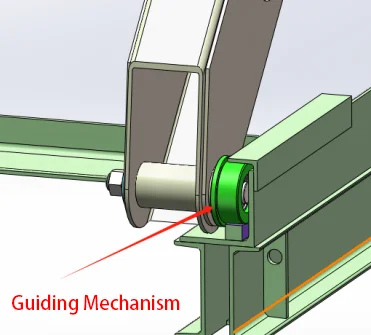

4. 안내 메커니즘

리프팅 시 장비의 안정성을 높이기 위해 4개의 가이딩 휠 어셈블리 세트로 구성됩니다.

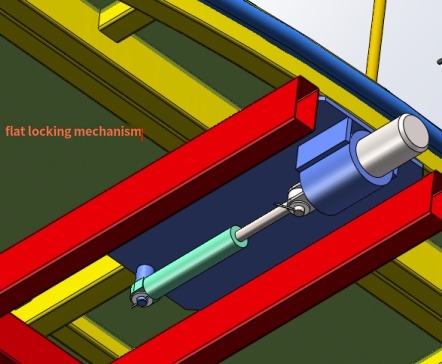

5. 레벨링 잠금 핀 메커니즘

장비가 장기간 작업 위치에 있을 때 실린더의 작용으로 4개의 수평 조절 잠금 핀 세트가 미리 제작된 구멍으로 확장되어 시간이 지나도 위치 정확도와 안정성을 보장합니다.

그림과 같이 수평 조절 잠금 핀 메커니즘에는 원형 플랫폼 아래에 용접된 실린더, 핀 샤프트 및 고정 플레이트가 포함되어 있어 내려가지 않고 위치를 유지할 수 있습니다.

6. 동기화 메커니즘

이 장비는 통합 플랫폼이 있는 2경간 구조로 구성되어 있습니다. 유압 시스템은 동기식 모터를 사용하여 동기화 정확도를 효과적으로 유지합니다.

펌프 스테이션은 오일을 동기식 모터로 보내고, 모터는 배출구 A와 B를 통해 두 세트의 시저 실린더로 오일을 분배하여 양쪽에 동일한 오일 흐름을 보장함으로써 시저 메커니즘의 안정적인 리프팅과 동기화를 보장합니다.