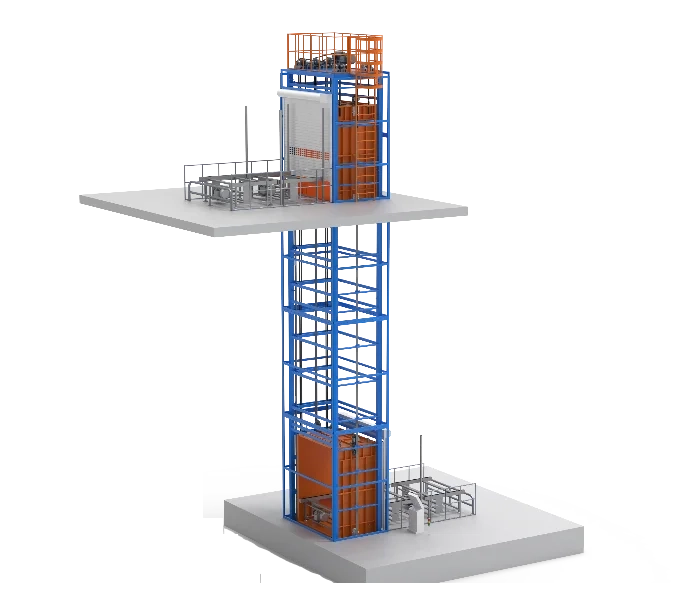

Elevador VRC de cuatro postes tipo Z

El transportador alternativo vertical (VRC) de 4 postes tipo Z es un sistema de transporte vertical flexible y eficiente, especialmente adecuado para aplicaciones que requieren carga y descarga desde lados opuestos o desde la parte delantera y trasera. El diseño del equipo permite cargar y descargar mercancías desde ambos lados o desde la parte delantera y trasera, proporcionando múltiples opciones de carga y descarga, lo que mejora enormemente la flexibilidad y eficiencia operativas. La estructura de 4 postes la hace ideal para manipular materiales de diversos tamaños y pesos, especialmente cargas grandes y pesadas. Su diseño permite un funcionamiento más sencillo en entornos con limitaciones de espacio, ahorrando espacio de forma eficaz y optimizando los procesos logísticos.

Más información hable con nuestro equipo

Especificación

Capacidad de carga máxima

- Alcance: 5-25 toneladas (personalizable superior)

- Características: La estructura de cuatro postes distribuye el peso uniformemente para cargas industriales pesadas como maquinaria y contenedores de transporte.

Modo de carga/descarga

- Tipo: Tipo Z (Through-Loading)

- Características: El diseño de extremo abierto permite el flujo bidireccional de material, eliminando el tiempo de giro (30%+ aumento de la eficiencia).

Altura de elevación

- Alcance: 5-20 metros

- Características: Sistema guiado de cuatro columnas que garantiza la estabilidad en aplicaciones de gran altura o de eje profundo (contrapesos opcionales >20 m).

Dimensiones de la plataforma

- Estándar: 2,5-6 m (ancho) × 1,8-4 m (profundidad)

- Características: Plataforma sin barreras con extensiones opcionales (0,5-2 m) para cargas de gran tamaño (palas de aerogeneradores, tuberías).

Características

Carga en Z: Admite carga en Z (carga y descarga por lados opuestos o por delante y por detrás), adaptándose a diversas necesidades logísticas.

🔹 Gran capacidad de carga: Adecuado para manipular materiales grandes, pesados o sobredimensionados, cumpliendo requisitos de carga elevados.

🔹 Transporte vertical eficiente: Proporciona un transporte vertical rápido y seguro, ahorrando tiempo de operación y mejorando la eficiencia del trabajo.

🔹 Garantía de seguridad: Equipada con múltiples elementos de seguridad, como finales de carrera, sistemas anticaída y pulsadores de parada de emergencia, que garantizan la seguridad de los operarios y del equipo.

Infórmese aquí

Opciones y accesorios

Sistemas de seguridad y control

- Sistema anticaídas redundante doble: Respaldo mecánico + hidráulico, autobloqueo en caso de corte de corriente.

- Anticolisión 3D LiDAR: Detección de cargas salientes en tiempo real

- Interfaz HMI multilingüe: Compatible con los idiomas CN/EN/PT/ES

Dispositivos de carga y extensiones de plataforma

- Placas de puente telescópicas bidireccionales: 0,5-2 m de extensión por lado

- Transportador de rodillos de alta resistencia: capacidad de 2 toneladas por rodillo, compatible con AGV

- Puertas de seguridad de apertura rápida: Plegado hidráulico con sensores de enclavamiento.

Kits de adaptación medioambiental

- Revestimiento anticorrosión C5-M: Para entornos costeros/marinos.

- Envase antideflagrante ATEX: Certificado para zonas peligrosas.

- Sistema hidráulico de alta temperatura: Funcionamiento estable a 80 °C de temperatura ambiente.

Accionamiento y eficiencia energética

- Accionamiento sincrónico hidráulico doble: Elevación y descenso suaves para cargas superiores a 30 toneladas, con una precisión de sincronización de ±1 mm.

- Recuperación de energía regenerativa: Recupera electricidad a la red durante el descenso, ahorrando energía 15-20%.

Este elevador ha mejorado significativamente nuestra eficiencia en la construcción. Su capacidad de carga de 8 toneladas y la función de carga bidireccional facilitan y agilizan el transporte de materiales pesados. El revestimiento resistente a la corrosión se comporta de forma excelente en nuestro entorno lluvioso, garantizando un uso a largo plazo. Tanto en lo que respecta a la utilización del espacio como a la seguridad operativa, este elevador es la elección ideal para nuestros proyectos.

Los equipos de manipulación de materiales de su industria

Los montacargas Gradin pueden utilizarse para transportar cargas de palés de productos acabados o ingredientes, o equipos, hacia arriba y hacia abajo desde una entreplanta o una segunda planta. La plataforma del elevador puede fabricarse en acero inoxidable para que cumpla la normativa, no sea corrosiva y pueda lavarse.

Teniendo en cuenta las lesiones musculoesqueléticas, a continuación se ofrece una lista útil, aunque no exhaustiva, de situaciones que suelen darse en los sectores de la fabricación y la ingeniería durante el proceso de producción:

- Manipulación repetida de la carga a distancia del tronco del cuerpo.

- Flexión repetida del tronco para levantar la carga.

- Una carga muy grande y difícil de asir.

- Manipulación repetida de la carga por encima de la altura de los hombros o a nivel del suelo.

- Levantamientos que impliquen torsión del tronco.

- La carga debe transportarse a gran distancia a través de una zona desordenada o peligrosa.

Cuando las actividades de manipulación manual entrañan tales riesgos de lesión (en particular para la espalda) debido a condiciones ergonómicas desfavorables, el principio básico es que el empresario debe adoptar medidas para reducir o eliminar el riesgo de lesión.

El elevador de mercancías Gradin está diseñado específicamente para transportar palés de tamaño estándar desde la fabricación hasta el almacenamiento en una entreplanta o un primer piso. Si una especificación estándar no cumple todos sus requisitos, también nos especializamos en configuraciones a medida, trabajando en colaboración con usted para garantizar que su solución final sea perfecta para su empresa, sus empleados y sus productos.