22.10.2025 / lectura de 6 minutos

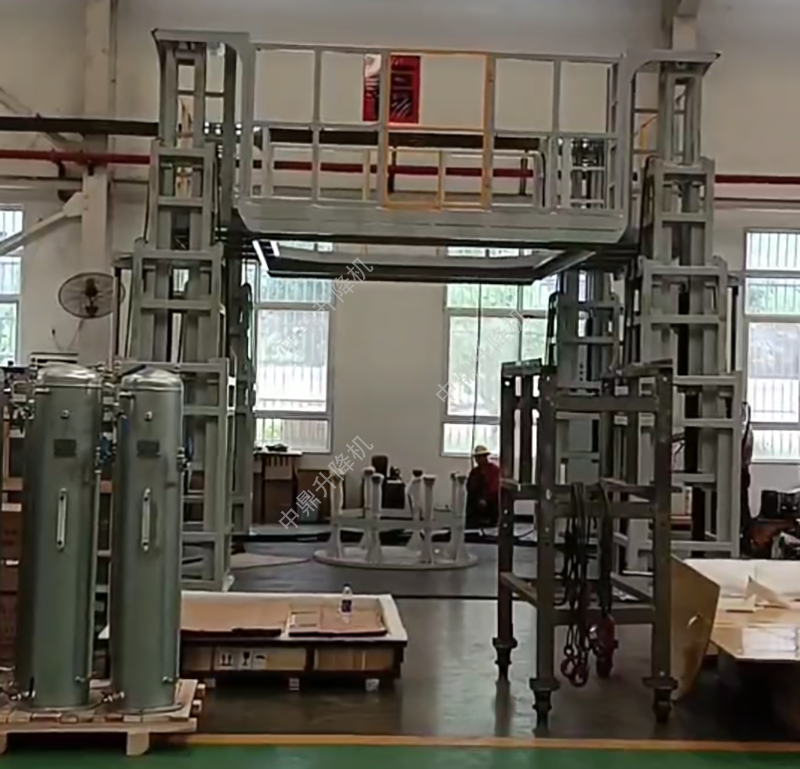

Mesas hidráulicas de giro y apilado de núcleos | 1-100 Ton

Visión general

Este análisis de caso profundiza en cómo la mesa hidráulica de torneado y apilado de núcleos aborda los principales retos de la fabricación tradicional de núcleos de transformadores, aportando mejoras revolucionarias en eficiencia y calidad para la producción de transformadores pequeños y medianos.

Gracias a su diseño modular, control hidráulico preciso, potente adaptabilidad a los procesos y excepcional fiabilidad estructural, la mesa hidráulica de torneado y apilado de núcleos se ha convertido en un activo clave indispensable en las modernas líneas de producción de núcleos de transformadores. No es simplemente una herramienta para conseguir una fabricación de núcleos de alta calidad, sino una fuerza motriz que impulsa el avance de los procesos y el aumento de la eficiencia rentable en la producción de transformadores.

Parámetros básicos

| Categoría de parámetros | Especificación Artículo | Detalles y especificaciones |

|---|---|---|

| Especificaciones básicas | Capacidad de carga | 1 ~ 100 toneladas (personalizable) |

| Tipos de núcleo compatibles | Núcleo trifásico, núcleo de cinco miembros, laminación | |

| Estructura de la plataforma | Combinación de bloques modulares (grande), diseño monobloque (pequeño) | |

| Métricas de precisión | Deformación de la superficie de la mesa | < 2 mm |

| Perpendicularidad (mesa de apilado frente a viga giratoria) | < 2 mm (antes y después del torneado) | |

| Mecánica y estructura | Ajuste del haz | Vigas que se mueven sincrónicamente a ambos lados |

| Sistema de accionamiento | Torneado accionado por cilindro hidráulico | |

| Velocidad de giro | Ajustable | |

| Características de seguridad | Patas de soporte de giro (para estabilidad tras un giro de 90°) | |

| Material del marco | Acero laminado en caliente o estructura soldada de bajo contenido en carbono, aliviado de tensiones | |

| Sistema hidráulico | Componentes clave | Componentes hidráulicos de marcas importadas (por ejemplo, cilindros) |

| Sincronización | Excelente sincronización, garantiza núcleo sin deformaciones | |

| Instalación y adaptabilidad | Requisitos de instalación | Grande: Necesita cimentación; Pequeño: Sin cimentación, Fácil de mover |

| Núcleo Ventana Adaptabilidad | Montaje flexible en función del tamaño de la ventana central, Gran adaptabilidad | |

| Dimensiones de la superficie de la mesa | Personalizado según los requisitos del cliente | |

| Compatibilidad de procesos | Procesos compatibles | Adecuado para Proceso de no extracción del yugo superior Proceso tradicional |

| Compatibilidad de las luminarias | La excelente sincronización garantiza núcleo sin deformaciones |

Retos y soluciones

- Desafíos tradicionales: El apilado y volteo tradicional de los núcleos dependía en gran medida de puentes grúa y mano de obra, lo que provocaba ineficacia, falta de sincronización y posibles problemas de seguridad. deformación del núcleoLa falta de seguridad y la escasa adaptabilidad a los distintos tamaños de ventanas.

- Optimización de procesos: La mesa permite atar el fleje mientras el alma está horizontal, lo que elimina la necesidad de complejas abrazaderas auxiliares utilizadas en el atado vertical, simplificando las operaciones y reduciendo el tiempo de ciclo. La Vigas que se mueven sincrónicamente en ambos lados se ajustan con precisión para adaptarse a diferentes diámetros de columna central (MO), garantizando una amplia aplicabilidad

Diseño de la fiabilidad

- Fiabilidad de los componentes básicos: Crítica los componentes hidráulicos (por ejemplo, cilindros) utilizan marcas importadasgarantizando la estabilidad operativa a largo plazo y alta fiabilidad de la fuente, reduciendo así los índices de fracaso.

- Resistencia estructural y precisión: El análisis de elementos finitos (FEA) se utiliza en la optimización del diseño, garantizando una resistencia y rigidez suficientes bajo carga (1-100 toneladas). Las métricas de alta precisión, como la deformación de la mesa <2 mm y el error de perpendicularidad <2 mm antes y después del torneado, proporcionan una base sólida para la calidad del apilado del núcleo. El diseño de las patas de soporte de giro ofrece una protección de seguridad adicional tras la rotación de 90 grados.