7.8.2025 / Lectura en 5 minutos

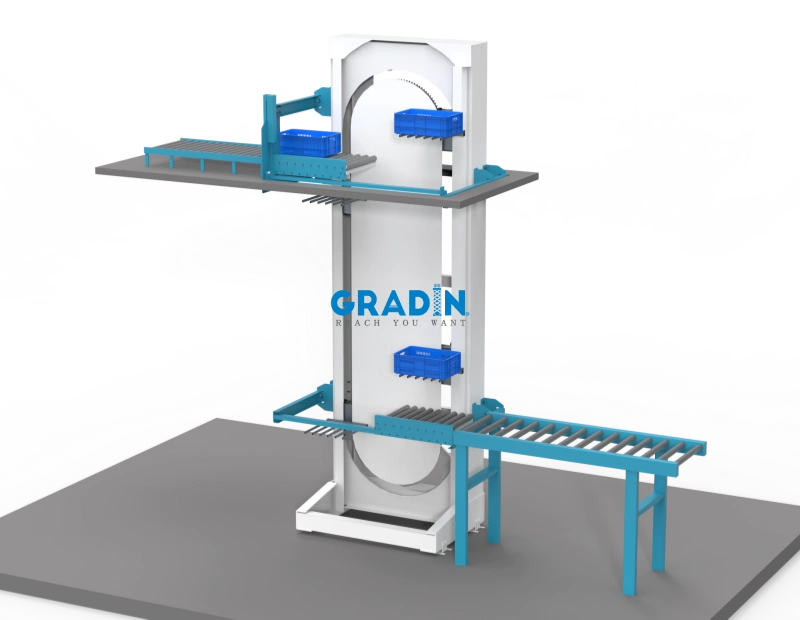

Sistema transportador de botellas PET vacías|Sistema de elevación vertical de alta velocidad

Visión general

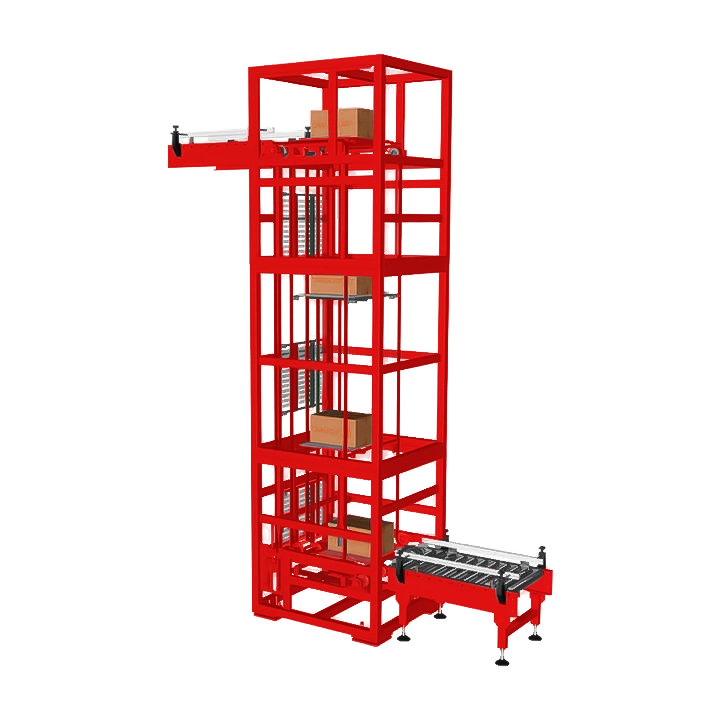

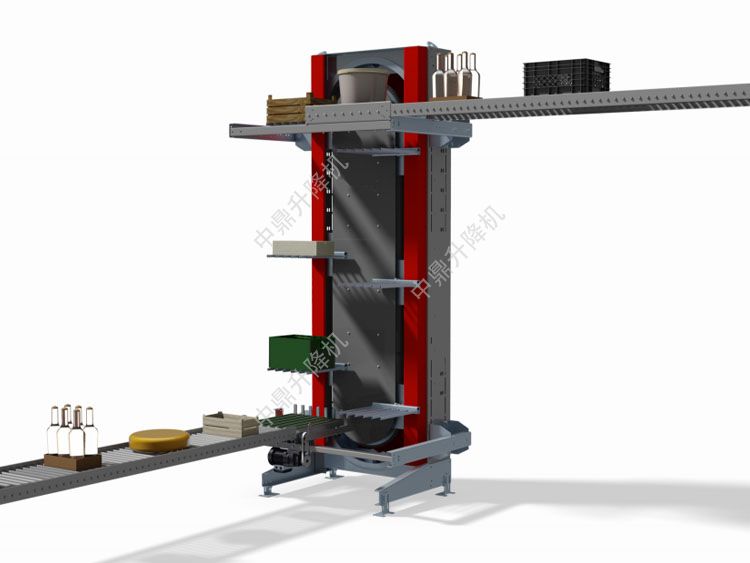

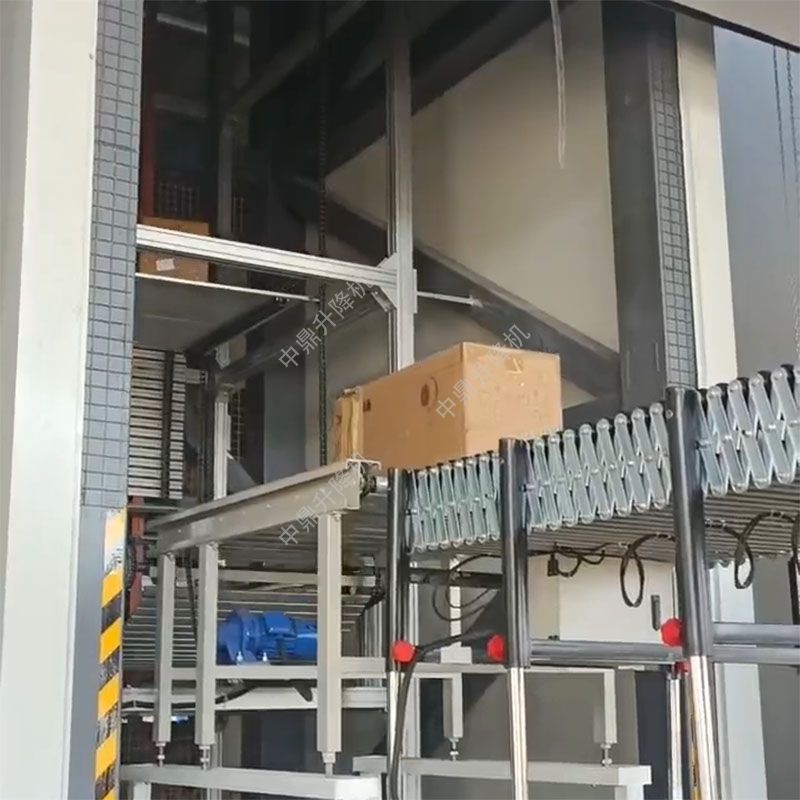

Alta velocidad transportador vertical continuo de horquilla diseñado para plantas de agua embotellada. Dispone de mecanismos de horquillas giratorias para el transporte sin huecos de envases vacíos o llenos entre las estaciones de llenado, taponado y paletizado. Cumple las estrictas normas de higiene con una capacidad de más de 20.000 botellas/hora.

- ✅ Sustituye la manipulación manual, elimina el volcado de botellas.

- ✅ El diseño de funcionamiento en seco (sin lubricación) evita la contaminación por agua.

- ✅ La estructura modular se adapta a las botellas de PET/jarras de 5 galones

Parámetros básicos

| Parámetro | Gama de especificaciones | Unidad | Notas |

|---|---|---|---|

| Capacidad | 15,000 – 36,000 | botellas/h | Basado en PET de 500 ml |

| Tipos de contenedores | Botellas PET/PC, garrafas de 5 galones | – | Ø50-300 mm |

| Altura de elevación | 3 – 20 | m | Cobertura de 2-6 plantas |

| Velocidad de funcionamiento | 0.25 – 0.8 | m/s | Control del servomotor |

| Posicionamiento Acc. | ±1 | mm | Requisitos de la línea de llenado |

| Material | SS304 (superficies de contacto) | – | Ra≤0,4μm electropulido |

| Potencia | 5.5 – 18.5 | kW | Depende de la carga/velocidad |

Ventajas técnicas

- ⚡ Eficiencia continua:

- El diseño de horquilla giratoria permite tiempo de espera cero (40%↑ vs alternativo)

- Dos canales independientes para el flujo simultáneo de envases vacíos/llenos

- 🛡️ Seguridad higiénica:

- Carcasa de acero inoxidable sellada con protección contra lavado IP69K

- Funcionamiento sin aceite: Cojinetes de polímero autolubricantes + cadenas secas alimentarias

- 🎯 Manejo preciso:

- Paso de horquilla autoajustable (50-300 mm)

- Pinzas de cuello de botella (índice de vuelco<0,01%)

- Conectividad inteligente:

- Sincronización PLC en tiempo real con rellenadoras (OEE≥95%)

- Memoria de cambio de envases (ajuste automático en 3 s)

Aplicaciones típicas

- Alimentación con biberón vacío: Zona de despaletización → Entrada de lavabotellas 2F

- Interfaz de llenado: Descarga de la llenadora → Entrada elevada de la taponadora.

- Manejo de la jarra llena: Línea de llenado de 5 galones → Ensacado/paletizado de 3F.

- Suministro de envases: Transporte vertical de bobinas de tapones/etiquetas

Beneficios básicos

| Dimensión | Métricas clave |

|---|---|

| Eficacia | Sincronización de línea 100%|Cero tiempo de inactividad |

| Ahorro de costes | 12 operarios/línea ahorrados|98% menos roturas ($70K+/año) |

| Garantía de calidad | 100% Manipulación sin contacto|Cero riesgo de contaminación |

| Ahorro de espacio | Huella 2,5×3 m (frente a hueco de ascensor) |

Opciones de personalización

| Personalización | Agua embotellada | Opciones estándar |

|---|---|---|

| Adaptación de contenedores | Pinzas antivuelco de PET|Brazos de soporte de tazas | Vidrio/lata herramientas especiales |

| Clase de higiene | Esterilización CIP|Pulido espejo (Ra≤0,2μm) | SS316L/2205 |

| Mejora de la velocidad | Versión Ultra-HS (50.000 botellas/h) | Selección de variador/servo |

| Medio ambiente | Alta humedad (95%RH)|Anticondensación | ATEX/Exterior |

| Funciones inteligentes | Contenedor de visión ID|AI prevención de atascos | Integración MES/ERP |