12.8.2025 / 5-minute read

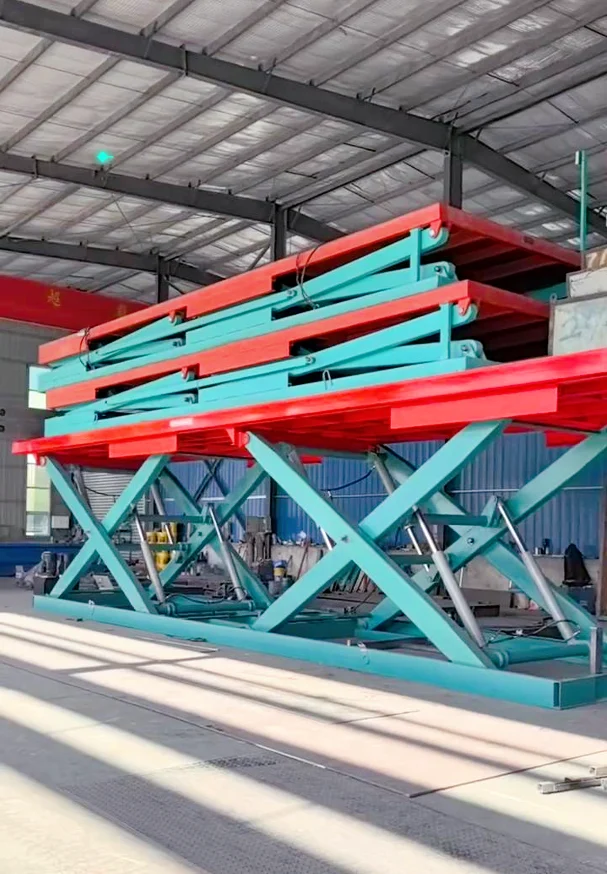

Heavy-Duty Lifting Platform for Paper Box Manufacturing

Visión general

In the paper converting and corrugated box manufacturing industry, efficient and safe handling of heavy rolls, stacked sheets, and production tools is critical to operational throughput.

This case study examines the implementation of a custom-engineered heavy-duty lifting platform in a mid-sized paper box factory, highlighting how tailored engineering solutions solve core material handling challenges.

Looking to optimize material handling in your paper or packaging operation? Contact our engineering team to discuss a customized lifting solution for your facility.

Parámetros básicos

| Categoría | Especificación | Details / Benefit |

|---|---|---|

| Modelo | HD-SLP-13/20 | Heavy-Duty Scissor Lifting Platform |

| Primary Application | Paper roll handling, palletized sheet transfer, die/service access in corrugated box & paper converting plants. | |

| Dimensiones de la plataforma | 13 m (L) x 3 m (W) | Optimized for full pallet rows, large paper rolls, and bulk material staging. |

| Capacidad de elevación | 20.000 kg | Engineered for heavy paper rolls, stacked board, and industrial loads. |

| Max Lift Height | 2.7 m | Ideal for feeding presses, conveyors, and automated production lines. |

| Mechanism | Twin-Scissor System | Provides superior stability and even load distribution across the full platform length. |

| Actuation | 8 Synchronized Hydraulic Cylinders | Ensures smooth, tilt-free lifting essential for delicate or uneven loads (e.g., paper stacks). |

| Support Structure | 300 mm Diameter Support Arms | High moment of inertia for maximum structural integrity under dynamic loads. |

| 15 mm Thickness (Arms) | High-strength steel construction for long-term durability in continuous industrial use. | |

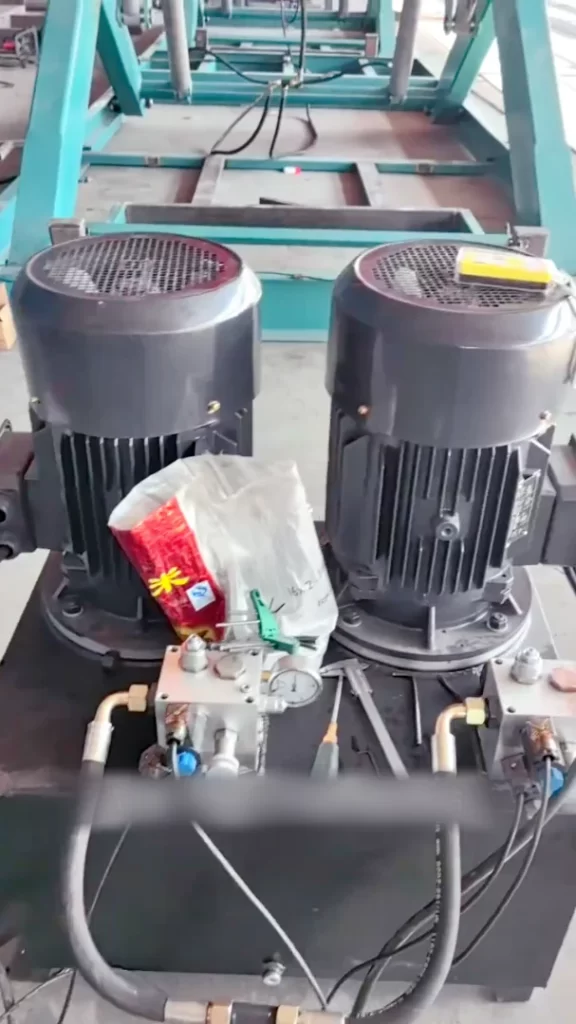

| Unidad de potencia | Dual 11 kW Hydraulic Pump Station | Provides reliable, consistent power for fast cycle times and 24/7 operation capability. |

| Sistema de control | Standard: Synchronized Lift | Customizable: Integration with PLCs, safety gates, or automated line controls available. |

Desafío

- Manual handling of large paper rolls (up to 20 tons) caused safety risks and required excessive labor.

- Inefficient transfer of stacked corrugated sheets between processing stages led to workflow delays.

- Existing equipment lacked the length, stability, and precision needed to align with modern converting machinery.

Solución

- Load Capacity: 20,000 kg, designed for continuous industrial cycles.

- Lift Height: 2.7 meters, optimized for feeding presses and automated lines.

- Diseño estructural: Twin-scissor mechanism with 8 synchronized hydraulic cylinders, ensuring even load distribution and platform stability.

- Reinforced Construction: 300mm diameter, 15mm thick high-strength steel support arms for maximum durability under dynamic loads.

- Power System: Dual 11 kW hydraulic pump station, providing reliable, smooth, and rapid lifting performance.