7.3.2025 / Lectura en 5 minutos

Elevador continuo de paquetes | Sistema de clasificación de 4000 piezas/hora | Transportador vertical de cero daños | Integración AS/RS

Visión general

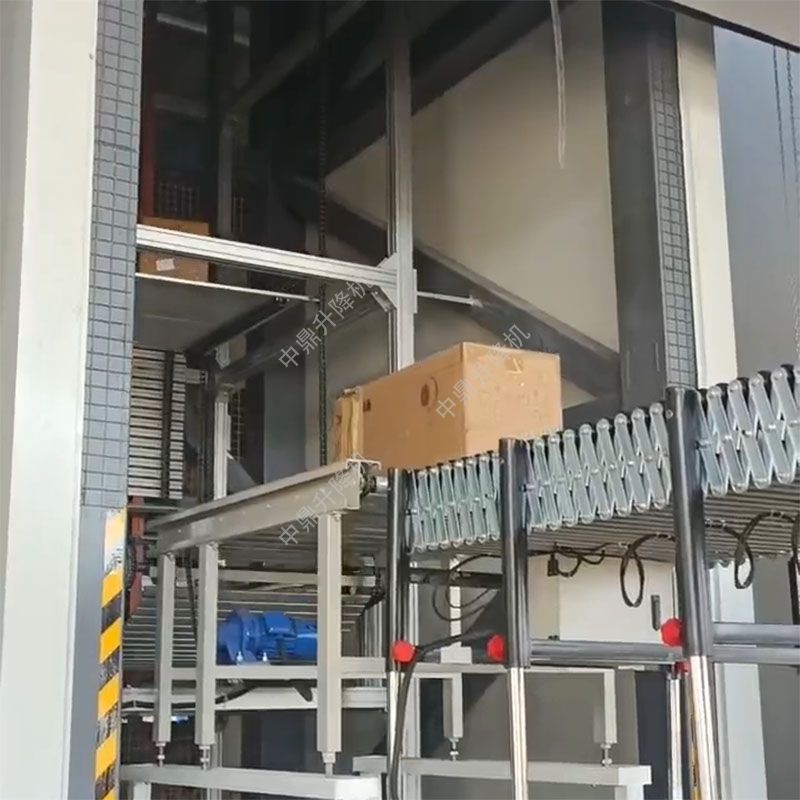

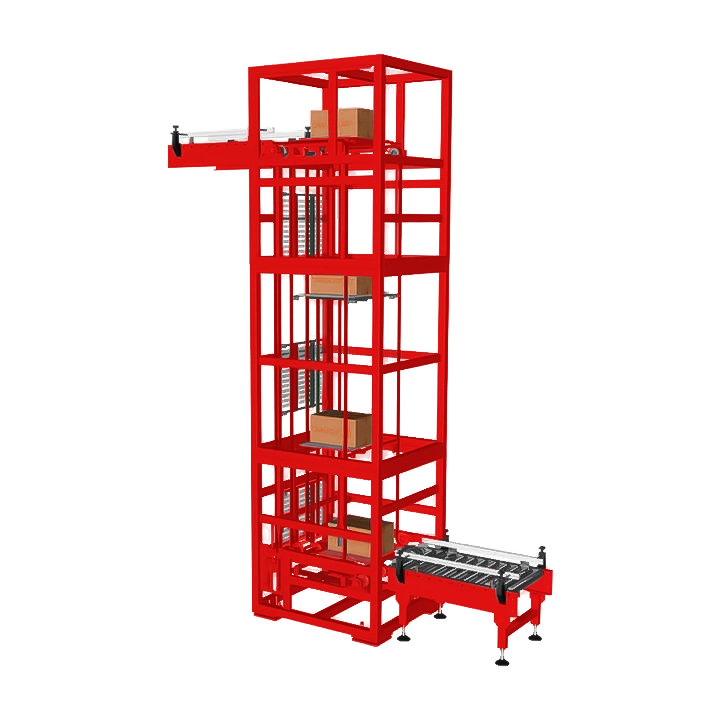

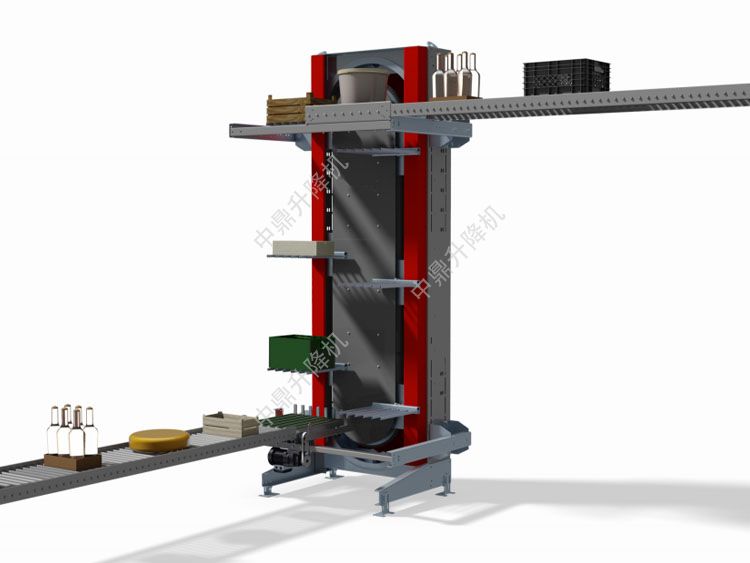

Transportador vertical continuo diseñado para centros de logística exprés. Dispone de accionamiento por correa/rodillo síncrono multietapa para transporte de paquetes sin huecos:

- Funcionamiento 24/7: Motores VFD + programación AI (≥4000 piezas/hora pico)

- Transferencia de impacto cero: Guías tampón dinámicas (control de separación ±5 cm)

- Adaptabilidad del tamaño: Para paquetes de 500-1200 mm (5-30 kg)

- Integración de clasificación inteligente: Lectura de códigos de barras/RFID con enrutamiento en tiempo real

Parámetros básicos

| Especificación | Valor |

|---|---|

| Capacidad | 3000-4000 piezas/hora |

| Tamaño de la parcela | L:500-1200mm |

| An:300-800mm | |

| Carga máxima | 30 kg/pieza |

| Velocidad | 0,8-1,5 m/s |

| Potencia | 5,5 kW/nivel |

| Ruido | ≤65dB(A) |

El desafío

- Límite de rendimiento: Los elevadores por lotes provocan tiempos muertos (pico<2000 pcs/hr)

- Daños en los paquetes: Transferencias de caída libre>0,5% Tasa de rotura

- Clasificación errónea: Precisión dinámica de escaneado de códigos de barras<95%

- Residuos de alta energía: Modelos convencionales>10kW de consumo eléctrico

Soluciones

- 2x Eficacia: 200% más rápido que los elevadores por lotes

- Ahorro de costes: <0.1% tasa de daño, 50% reducción de trabajo

- Smart Ready: Integración de WCS con robots clasificadores

- Despliegue rápido: Montaje modular (72 horas de preparación)

Ventajas

- Seguridad intrínseca:

- Doble freno + cabina certificada FOPS/ROPS (resistencia a impactos de 10t); reducción de accidentes 90%.

- Eficiencia operativa:

- 30% carga más rápida mediante acceso por tres lados (tiempo de ciclo ≤15 seg/unidad).

- Preparado para entornos extremos:

- Rango de temperaturas: de -30°C a +40°C; compatible con salas blancas de clase 1000.

- Durabilidad:

- Mástil de acero Q345A + transmisión por rodamientos de rodillos (100.000 horas de vida útil).

Escenarios de aplicación

- Centros regionales: Integración con el clasificador de cinta transversal

- Terminales aeroportuarias: Conectar escáneres de seguridad

- Almacenes de comercio electrónico: Sincronización con sistemas put-wall

- Estaciones de última milla: Clasificación compacta multinivel