13.6.2025 / 4 minutos de lectura

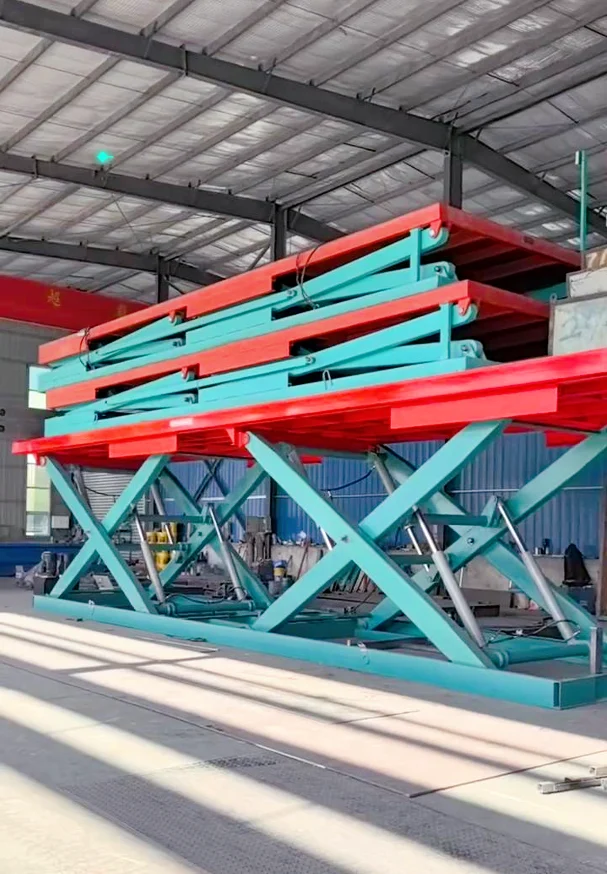

Plataforma de mantenimiento para pruebas en túnel aerodinámico | Elevador de tijera de gran resistencia para pruebas de motores

Resumen del proyecto

Este elevador de tijera fijo de alta resistencia está diseñado para el mantenimiento de motores de aeronaves en celdas de prueba de túneles de viento. Instalado a la entrada del túnel, proporciona a los técnicos una plataforma estable y de posicionamiento preciso durante el funcionamiento del motor a pleno empuje.

El sistema utiliza válvulas proporcionales para el control sincrónico de varias unidades de elevación, integra potenciómetros de cadena para la retroalimentación de carrera en tiempo real e incorpora compuertas giratorias bidireccionales de acero inoxidable con supervisión de posición para garantizar la seguridad operativa y el cumplimiento de las normas.

Parámetros básicos

| Parámetro | Especificación |

|---|---|

| Tipo | Elevador de tijera fijo para cargas pesadas |

| Aplicación | Mantenimiento del túnel de viento de motores de aeronaves |

| Control de sincronización | Válvula proporcional hidráulica de bucle cerrado |

| Feedback de posicionamiento | Potenciómetros de cadena de alta precisión (por unidad) |

| Sistema de compuertas | Puertas batientes de acero inoxidable de ancho completo |

| Control de seguridad | Finales de carrera de posición de puerta cerrada |

| Capacidad de carga | ≥10 toneladas (peso típico del motor) |

| Altura de elevación | 8-12 metros (adaptado a la célula de prueba) |

| Tamaño de la plataforma | Cobertura total (interfaz de túnel) |

| Precisión de sincronización | ≤±2mm (Error dinámico multicilindro) |

El desafío

- Sincronización multicilíndrica: Mantener la sincronización a nivel milimétrico de unidades de tijera de carga pesada bajo cargas dinámicas.

- Estabilidad operativa: Resisten las vibraciones y las perturbaciones aerodinámicas durante las pruebas de motores a pleno empuje.

- Enclavamiento de seguridad: Enclavamiento del elevador por cable para evitar operaciones peligrosas.

- Posicionamiento de carrera larga: Sensores de retroalimentación de alta precisión para desplazamientos de >10 m en entornos difíciles.

Soluciones

- Control síncrono de bucle cerrado

- Las válvulas proporcionales ajustan el caudal hidráulico basándose en la retroalimentación del potenciómetro de cadena en tiempo real, lo que permite la corrección dinámica PID.

- Diseño estructural robusto

- Brazos de tijera reforzados y bastidor de base ancha para soportar las cargas laterales del viento y las vibraciones del motor.

- Sistema de enclavamiento de seguridad

- Interruptores de posición de la puerta integrados en el control PLC; el funcionamiento del ascensor sólo se activa cuando se verifica el cierre de la puerta.

- Detección industrial

- Potenciómetros de cuerda con clasificación IP67 resistentes al aceite, el polvo y las interferencias electromagnéticas para un posicionamiento fiable en carreras largas.

Ventajas

✅ Sincronización de precisión: ≤±2mm de error multicilíndrico mediante control en bucle cerrado.

✅ Cumplimiento de las normas de seguridad: El enclavamiento del elevador de la puerta cumple los requisitos de la norma ISO 13849 SIL 2.

✅ Plena resistencia medioambiental: Acero inoxidable resistente a la corrosión, sistema hidráulico de alta temperatura (-20℃~60℃).

✅ Mantenimiento optimizado: El diseño de la puerta de acceso abierto y la estructura modular agilizan el mantenimiento.

✅ Trazabilidad de los datos: El controlador registra la posición de elevación, el error de sincronización y el estado de la puerta para el diagnóstico.