8.5.2025 / Lectura de 5 minutos

Sistema de elevación sincronizada de doble tijera: Solución de problemas de montaje industrial pesado con precisión milimétrica

Resumen del proyecto

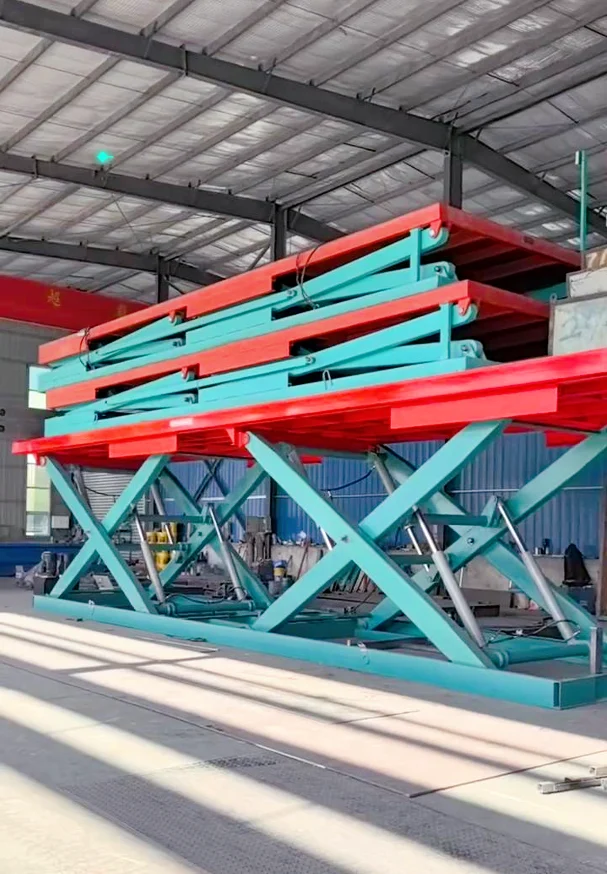

Esta plataforma elevadora sincronizada de doble tijera, diseñada a medida para la fabricación y el montaje industrial, eleva cargas de 3.000 kg a 4 m de altura mediante un sistema hidráulico sincronizado, sustituyendo la manipulación manual y aumentando la eficacia y la seguridad.

Parámetros básicos

| Modelo de producto | SJG3.0-4.0 |

|---|---|

| Tamaño de la plataforma elevadora | 2000*750mm |

| Espacio requerido Tamaño | 2100*850mm |

| Altura de carrera | 4000 mm |

| Carga nominal | 3000kg |

| Altura propia del equipo | 800 mm (incluye la altura de las ruedas, cuatro ruedas universales) |

| Velocidad de elevación | 2-3m/min |

| Pintura general | Amarillo + Negro |

| Estructura | Dos horquillas de tijera + motor síncrono + estación de bombeo hidráulico + sistema de control |

| Estructura de horquilla de tijera | Un vano, tres capas |

El desafío

- Precisión de sincronización: Los brazos de tijera dobles deben elevarse de forma sincronizada (desviación ≤2mm) para evitar la inclinación de la carga o la sobrecarga hidráulica.

- Conformidad de seguridad: Certificación CE que requiere informes FMEA y pruebas de sobrecarga 150%.

- Integración compacta: Alojamiento de las unidades hidráulicas y de control en un espacio de 2100×850 mm (800 mm de altura propia con ruedas).

Soluciones

- Sistema hidráulico de bucle cerrado: El divisor de caudal síncrono + los sensores de desplazamiento consiguen una desviación <1,5 mm.

- Redundancia de seguridad: Válvulas de equilibrado + bloqueos mecánicos para la seguridad en caso de fallo de alimentación; 120% probado en carga con informes SGS.

- Optimización del espacio: Unidades hidráulicas/de control empotradas en la base de la tijera con conductos de refrigeración para entornos de 40℃.

Ventajas

✅ Sincronización por debajo de 2 mm: Garantiza la estabilidad de la carga y prolonga la vida útil.

Cumplimiento total: Certificado CE con informes de pruebas para clientes de todo el mundo.

✅ Ahorro de mano de obra: la velocidad de 2-3m/min reduce 3 horas de mano de obra por ciclo, reduciendo los plazos en 30%.

Espacio inteligente: Ruedas + perfil bajo se adaptan a espacios reducidos.

✅ Heavy-Duty: Acero al manganeso + varillas cromadas para 100k ciclos durante 10 años.