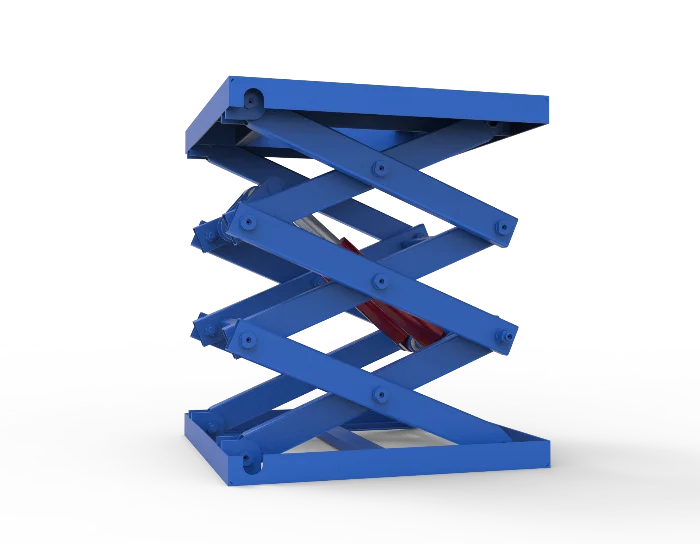

Mesa elevadora de tijera hidráulica para cargas pesadas

Este elevador está diseñado para resolver el problema de la manipulación y elevación de objetos pesados con la máxima fiabilidad. La capacidad de carga de este elevador puede adaptarse a su tonelaje, lo que lo hace ideal para una gran variedad de aplicaciones industriales pesadas. Utiliza un sistema hidráulico para garantizar un funcionamiento sencillo y facilitar la elevación y el descenso de mercancías sin interrupciones, mejorando así la eficacia operativa. Este elevador se fabrica a medida utilizando acero de alta resistencia y componentes de alta calidad para garantizar una estabilidad y fiabilidad inigualables incluso en los entornos de trabajo más exigentes.

Más información hable con nuestro equipo

Especificación

- Capacidad de carga nominal: 10 toneladas - 400 toneladas

Las plataformas elevadoras de tijera para cargas pesadas estándar suelen soportar entre 10 y 100 toneladas, mientras que los modelos industriales personalizados pueden llegar hasta las 400 toneladas para maquinaria pesada, materiales de construcción o logística de líneas de producción. - Plataforma compacta: 1,5m × 1m - 3m × 2m (Espacio eficiente para áreas confinadas)

- Plataforma grande: 5m × 3m - 10m × 6m (Superficie ampliada para materiales voluminosos o en lotes)

- Alcance de elevación: 0,2m - 12m.

Alcance bajo (0,2-2 m) para alineación de precisión; alcance alto (8-12 m) para trabajos en almacenes o aéreos. Alturas personalizadas disponibles. - Presión del sistema hidráulico: 20 MPa - 30 MPa.

El sistema hidráulico de alta presión garantiza una elevación suave y controlada. 25 MPa es lo habitual, equilibrando potencia y eficiencia energética. - Potencia del motor: 15 kW - 75 kW.

Tamaño adaptado a los requisitos de carga y velocidad. Los modelos pesados suelen utilizar motores de 30-50 kW con variadores de frecuencia para controlar la velocidad de forma continua. - Umbral de seguridad de sobrecarga: 110% - 150% de carga nominal.

Los sensores activan el bloqueo automático a una capacidad de 110%; algunas aplicaciones de alta seguridad permiten hasta 150%. - Material: Acero de alta resistencia Q345B (resistencia a la tracción ≥470 MPa), con refuerzos de acero aleado para los componentes críticos.

- Velocidad de elevación: 0,1-0,5 m/s (servicio pesado de baja velocidad) o 0,5-1 m/s (eficacia equilibrada).

- Fuente de alimentación: 380 V trifásica (estándar) o diésel (para uso en exteriores o fuera de la red).

Características

🔹 Gran capacidad de carga: Con una capacidad de elevación de hasta 400 toneladaspuede manipular objetos pesados de forma eficiente y eficaz.

🔹 Sistema hidráulico: Utiliza un sistema hidráulico fiable para lograr operaciones de elevación y descenso suaves y controladas.

🔹 Mayor seguridad: Equipada con funciones de seguridad como protección contra sobrecargas y bloqueos de seguridad para garantizar operaciones de elevación seguras.

🔹 Estructura duradera: Hecho de materiales resistentes como el acero de alta resistencia, puede satisfacer las necesidades de aplicaciones industriales pesadas

Infórmese aquí

Opciones y accesorios

Características de seguridad

- Sistema de protección contra sobrecargas (supervisión en tiempo real y limitación de la carga)

- Válvula de seguridad anticaída (evita caídas repentinas por fallo de la línea hidráulica)

- Dispositivo de protección de límite (controla la altura de elevación dentro de rangos seguros)

- Descenso manual de emergencia (permite un descenso seguro durante los cortes de energía)

Opciones de potencia

- Accionamiento hidráulico (ideal para situaciones de carga elevada, rendimiento estable)

- Accionamiento eléctrico (adecuado para elevaciones frecuentes y operaciones de alta eficiencia)

- Motor diesel (para uso en exteriores sin alimentación eléctrica)

Componentes estructurales

- Bastidor de acero al manganeso de alta resistencia (soporta cargas de varias toneladas)

- Mecanismo de tijera de doble capa/doble fila (mejora la estabilidad para cargas pesadas)

Funciones adicionales

- Chasis móvil (con ruedas giratorias o kits de remolque para facilitar la reubicación)

- Extensión de plataforma (amplía el espacio de trabajo para aplicaciones variadas)

- Panel de control inteligente (funcionamiento multipunto con botones a nivel del suelo)

Componentes del sistema hidráulico

- Válvula de equilibrio y válvula de alivio (regula la presión hidráulica)

- Válvula solenoide antideflagrante (mejora la seguridad del control)

Control y funcionamiento

- Mando a distancia (funcionamiento inalámbrico de elevación/movimiento)

- Alarma de nivel (supervisa la inclinación de la plataforma en tiempo real)

Movilidad y estabilización

- Superficie de plataforma antideslizante (mejora la seguridad en el lugar de trabajo)

- Barandillas plegables (barreras de protección ajustables)

- Kit de anclaje (asegura la grúa para evitar desplazamientos)

Herramientas de mantenimiento

- Aceite hidráulico y filtros específicos (consumibles de mantenimiento rutinario)

- Kit de reparación de emergencia (incluye piezas de repuesto esenciales)

Orgullosos de suministrar equipos de manipulación de materiales a todas las industrias y para todas las aplicaciones

Los equipos de manipulación de materiales de su industria

Los montacargas Gradin pueden utilizarse para transportar cargas de palés de productos acabados o ingredientes, o equipos, hacia arriba y hacia abajo desde una entreplanta o una segunda planta. La plataforma del elevador puede fabricarse en acero inoxidable para que cumpla la normativa, no sea corrosiva y pueda lavarse.

Teniendo en cuenta las lesiones musculoesqueléticas, a continuación se ofrece una lista útil, aunque no exhaustiva, de situaciones que suelen darse en los sectores de la fabricación y la ingeniería durante el proceso de producción:

- Manipulación repetida de la carga a distancia del tronco del cuerpo.

- Flexión repetida del tronco para levantar la carga.

- Una carga muy grande y difícil de asir.

- Manipulación repetida de la carga por encima de la altura de los hombros o a nivel del suelo.

- Levantamientos que impliquen torsión del tronco.

- La carga debe transportarse a gran distancia a través de una zona desordenada o peligrosa.

Cuando las actividades de manipulación manual entrañan tales riesgos de lesión (en particular para la espalda) debido a condiciones ergonómicas desfavorables, el principio básico es que el empresario debe adoptar medidas para reducir o eliminar el riesgo de lesión.

El elevador de mercancías Gradin está diseñado específicamente para transportar palés de tamaño estándar desde la fabricación hasta el almacenamiento en una entreplanta o un primer piso. Si una especificación estándar no cumple todos sus requisitos, también nos especializamos en configuraciones a medida, trabajando en colaboración con usted para garantizar que su solución final sea perfecta para su empresa, sus empleados y sus productos.