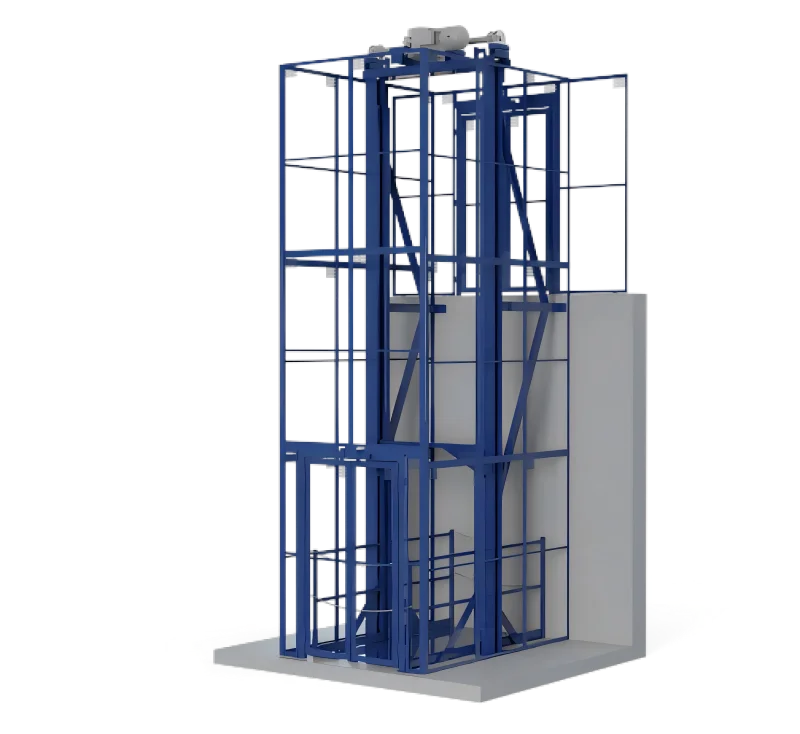

Plataforma elevadora VRC

El elevador de horquilla VRC cuenta con un carro situado entre dos columnas guía, lo que distribuye el peso de la carga uniformemente a lo largo de ambas columnas. En comparación con una configuración en voladizo, este diseño ofrece una mayor capacidad de carga y una plataforma de carro más amplia, a la vez que soporta mayores fuerzas de vuelco generadas durante la carga y descarga. La disposición en horcajadas admite tanto la carga en C (carga y descarga desde la parte delantera) como la carga en Z (carga y descarga desde lados opuestos), por lo que resulta ideal para aplicaciones sin limitaciones de espacio y sin necesidad de una altura de carga ilimitada.

Más información hable con nuestro equipo

Especificación

Capacidad de carga máxima

- Alcance: 2-10 toneladas métricas (en función del modelo)

- Punto clave: La configuración de horquilla de doble columna distribuye el peso uniformemente, ofreciendo 30-50% mayor capacidad que los ascensores en voladizo.

Dimensiones de la plataforma

- Tamaño típico: 1,5-3 m (ancho) × 2-4 m (profundidad) (personalizable)

- Punto clave: La plataforma más grande admite cargas sobredimensionadas y permite acceso directo con carretilla elevadora sin riesgos para la estabilidad.

Altura máxima de elevación

- Alcance: 6-20 m (recorrido vertical, sin límites de piso intermedio)

- Punto clave: La rigidez de doble columna garantiza la estabilidad manipulación de materiales a gran altitud.

Resistencia al momento de vuelco

- Umbral: ≥5 kN-m (resistencia a la carga dinámica)

- Punto clave: El diseño Straddle resiste fuerzas laterales durante la carga/descargasuperando a los elevadores en voladizo (normalmente ≤2 kN-m).

Modos de carga y descarga

- Modos admitidos:

- "Tipo C" (carga frontal)

- "Tipo Z" (carga directa desde el lado opuesto)

- Punto clave: Permite flujo de trabajo bidireccional para almacenes o líneas de producción, mejorando la eficiencia del espacio al 40%+.

Características

🔹 Diseño de armario mínimo para una mayor rentabilidad: Utiliza la menor cantidad de estructura de cerramiento para garantizar la seguridad a la vez que optimiza la rentabilidad.

🔹 Opciones de carga y descarga: Admite carga en C (entrada y salida por el mismo lado) y carga en Z (entrada y salida por el lado opuesto) para adaptarse a diferentes flujos de trabajo logísticos.

🔹 Adaptable a diversos tamaños de carga: El diseño flexible maneja fácilmente materiales de diferentes tamaños y pesos.

🔹 Transporte vertical eficaz: Traslada mercancías de forma rápida y segura entre varias plantas, mejorando la eficiencia operativa.

Infórmese aquí

Opciones y accesorios

🔹Dispositivos de carga y descarga

- Plataforma autonivelante: Compensación de inclinación hidráulica/eléctrica (±2°) para una alineación perfecta del suelo.

- Placas puente extensibles: Extensiones de 0,5-1,5 m para salvar huecos entre pisos.

🔹Mejoras de seguridad

- Cortinas de luz infrarroja/bordes de seguridad: Detección de obstáculos con parada de emergencia (conforme a ANSI/ASME B20.1).

- Bloqueos mecánicos anticaídas: Bloqueo automático durante la pérdida de potencia para evitar el descenso de la plataforma.

🔹Adaptaciones medioambientales

- Calentadores anticondensación: Evitan la formación de hielo en cámaras frigoríficas (-30°C).

- Recubrimientos resistentes a la corrosión: Recubrimientos de cincado/epoxi (grado C5-M) para entornos difíciles.

🔹Integración de la automatización

- Escáneres RFID/códigos de barras: Autoidentificación de cargas para logística no tripulada.

- Control por PLC + pantalla táctil: Preajustes para varias plantas, compatibilidad con ERP/MES.

🔹Personalización de la plataforma

- Superficies antideslizantes: Acero con patrón de diamante (coeficiente de fricción ≥0,6).

- Barandillas plegables/modulares: Ajustable para diferentes tamaños de carga.

🔹Recuperación de energía

Frenado regenerativo: Convierte la energía gravitatoria en electricidad, ahorrando 15-20% de energía.

| Industria | Accesorios clave | Propósito |

|---|---|---|

| Alimentación/Farmacia | Acero inoxidable (304/316L), grasa alimentaria | Conformidad con la FDA, resistencia al lavado. |

| Automoción | Orugas de rodillos resistentes (1 tonelada/rueda) | Interfaces de acoplamiento AGV, resistencia a los impactos. |

| Aeroespacial | Plataformas de fibra de carbono + revestimientos ESD | 30% reducción de peso, protección estática. |

| Almacenamiento | Sistemas de puertas con enclavamiento | Impedir el acceso durante el funcionamiento. |

Kits de mantenimiento predictivo: Sensores de vibración/temperatura para controlar el desgaste en tiempo real.

Ampliación modular: Preinstalación para complementos (iluminación, sistemas de pesaje, etc.).

El elevador a horcajadas Gradin VRC revolucionó nuestro almacén: su diseño de doble columna permite manipular cargas de 4 toneladas sin balanceo y la carga tipo Z reduce drásticamente el tiempo de transferencia. Las opciones añadidas de RFID y autonivelación aumentaron la eficiencia en 40%. El mantenimiento es mínimo en comparación con los elevadores hidráulicos, y el cumplimiento de la normativa OSHA es una gran ventaja. Una bestia robusta que ahorra espacio para cargas pesadas. La mejor inversión para el transporte vertical industrial.

Los equipos de manipulación de materiales de su industria

Los montacargas Gradin pueden utilizarse para transportar cargas de palés de productos acabados o ingredientes, o equipos, hacia arriba y hacia abajo desde una entreplanta o una segunda planta. La plataforma del elevador puede fabricarse en acero inoxidable para que cumpla la normativa, no sea corrosiva y pueda lavarse.

Teniendo en cuenta las lesiones musculoesqueléticas, a continuación se ofrece una lista útil, aunque no exhaustiva, de situaciones que suelen darse en los sectores de la fabricación y la ingeniería durante el proceso de producción:

- Manipulación repetida de la carga a distancia del tronco del cuerpo.

- Flexión repetida del tronco para levantar la carga.

- Una carga muy grande y difícil de asir.

- Manipulación repetida de la carga por encima de la altura de los hombros o a nivel del suelo.

- Levantamientos que impliquen torsión del tronco.

- La carga debe transportarse a gran distancia a través de una zona desordenada o peligrosa.

Cuando las actividades de manipulación manual entrañan tales riesgos de lesión (en particular para la espalda) debido a condiciones ergonómicas desfavorables, el principio básico es que el empresario debe adoptar medidas para reducir o eliminar el riesgo de lesión.

El elevador de mercancías Gradin está diseñado específicamente para transportar palés de tamaño estándar desde la fabricación hasta el almacenamiento en una entreplanta o un primer piso. Si una especificación estándar no cumple todos sus requisitos, también nos especializamos en configuraciones a medida, trabajando en colaboración con usted para garantizar que su solución final sea perfecta para su empresa, sus empleados y sus productos.