8.20.2025 / 4-minute read

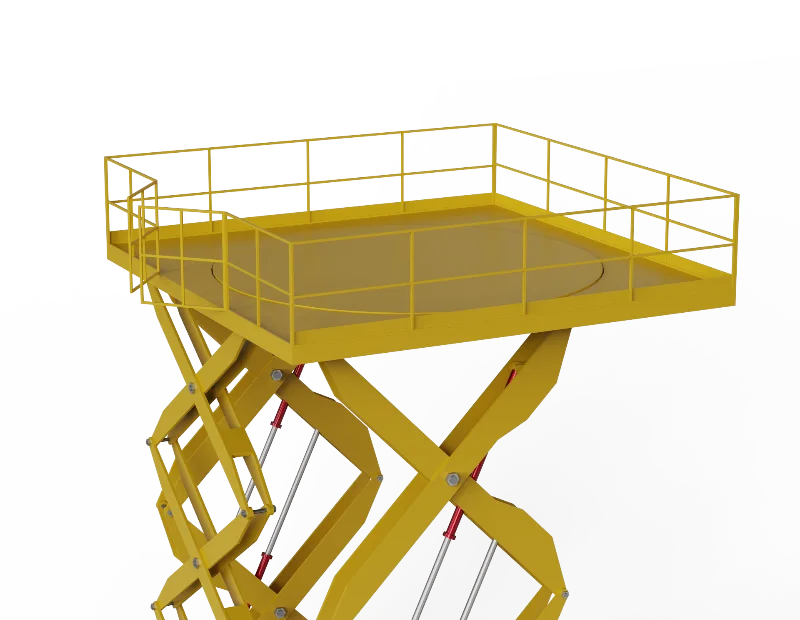

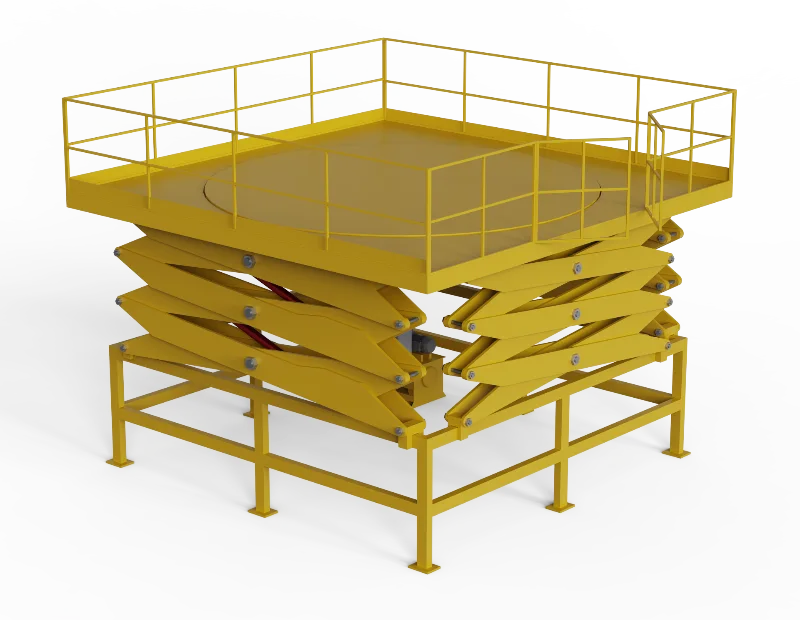

Heavy-Duty Vertical Assembly Platform – for Secure and Efficient Large Energy Turbine Installation

Project Overview

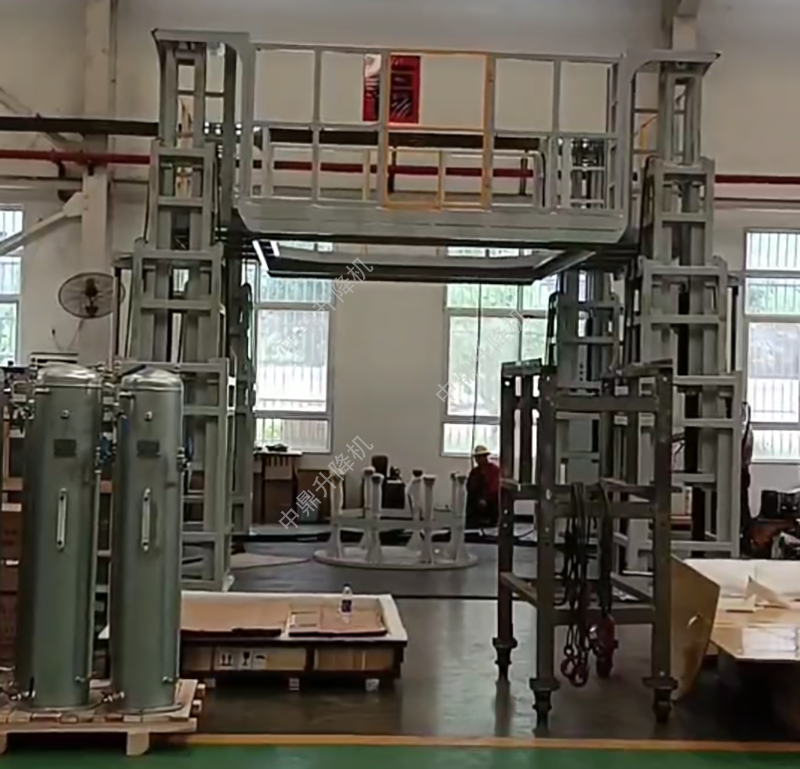

This project involved the design and provision of a vertical assembly platform for the installation process of large energy turbines.

The heavy-duty scissor lift is mounted within a ground pit and is engineered to safely elevate personnel, tools, and heavy components during assembly.

With a maximum raised height of nearly 35 feet, it effectively addresses the challenges of high-altitude installation on large equipment, integrating safety, stability, and modular customization.

Basic Parameters

| Parameter | Value / Description |

|---|---|

| Type | Heavy-Duty Scissor Lift |

| Vertical Travel | 260 inches (approx. 21.7 ft) |

| Max Raised Height (from pit) | 350 inches (approx. 29.2 ft) |

| Lowered Height | < 8 ft |

| Rated Rise Speed | 2 inches/second (Hydraulic) |

| Descent Method | Gravity descent with hydraulic velocity fuses |

| Safety Locking Mechanism | Mechanical lock-up bars (for maintenance) |

| Platform Deck | 3 x Removable round plates (customizable sizes) |

| Power Source | Hydraulic System |

The Challenge

1. Achieving long-stroke, high-load lifting within a confined pit space, while meeting extremely high stability requirements for the equipment.

2. The high value and precise installation requirements of large turbine components meant that any accidental descent or instability could lead to significant economic loss and safety hazards.

3. Hydraulic systems have a potential risk of leakage or failure under long-term and frequent use, necessitating reliable safety redundancy.

4. The working deck needed to be adaptable for handling different tools and tasks, requiring a versatile and modular panel design.