7.14.2025 / 5-minute read

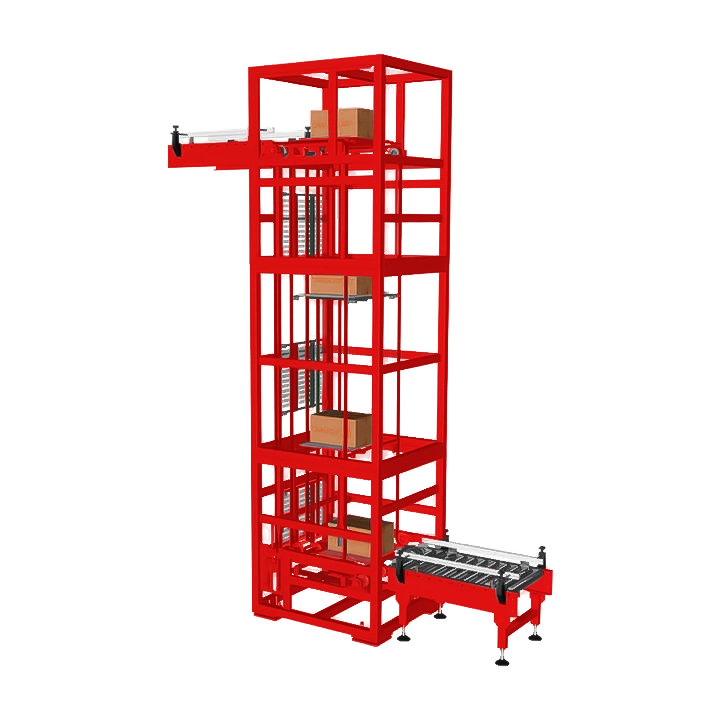

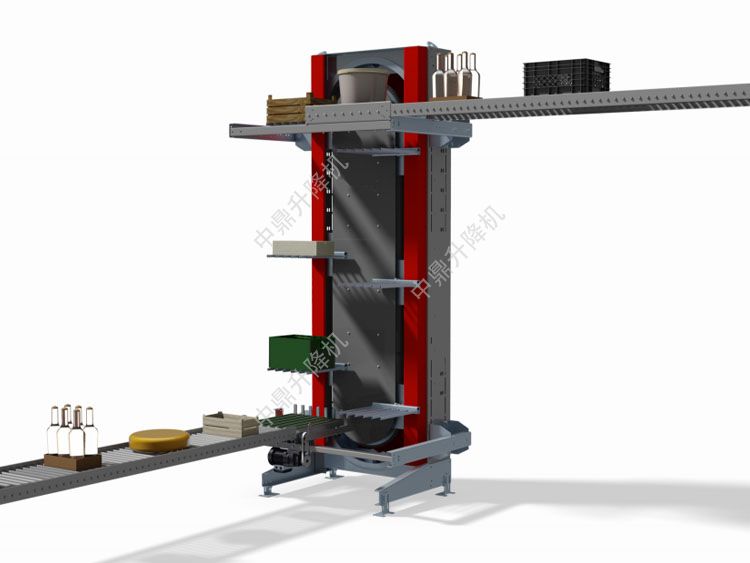

Fork-Arm Tote Lift|3,600 U/H E-commerce Sorting

Overview

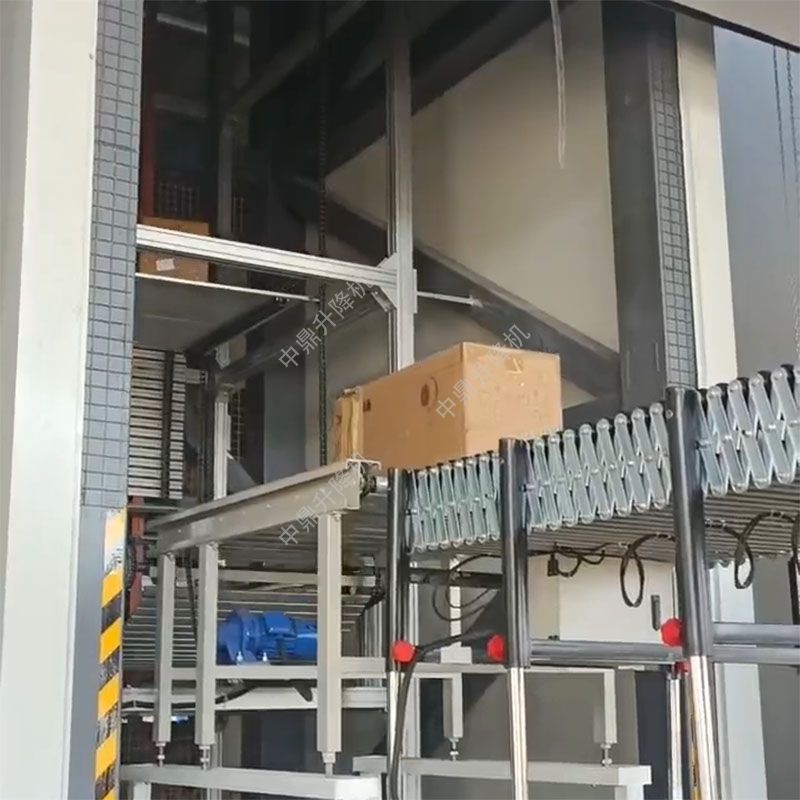

Designed for e-commerce sorting centers, the fork-arm reciprocating lift enables continuous vertical transport of totes between multi-level sorting lines.

Standard model fits 600×400mm totes with 3,600 units/hour throughput, eliminating manual handling errors.

Basic Parameters

| Parameter | Specification |

|---|---|

| Tote Size | 600×400×300mm (L×W×H) |

| Capacity | 3,600 totes/hour |

| Lift Height | 4-15m (3-5 floors) |

| Positioning Acc. | ±5mm (Laser guidance) |

| Drive Power | 7.5kW servo motor (TAILI) |

| Control System | PLC+Machine vision (Siemens) |

| Material | SS304 contact surfaces |

Material Configuration

- ⏱️ 2X Sorting Efficiency

Dual forks alternate operation, 50% faster than reciprocating lifts - 📦 Zero Tote Damage

Adaptive pressure control (50-300N adjustable) - 📊 Intelligent Dispatching

Dynamic prioritization based on line congestion prediction - 🛡️ 24/7 Operation

Maintenance-free chains (IWIS) for 100,000h service

Performance Metrics

| Metric | Manual Handling | This System | Improvement |

|---|---|---|---|

| Sorting Rate | 800 u/h | 3,600 u/h | +350% |

| Mis-sort Rate | 1.2% | 0.05% | -96% |

| Tote Damage Rate | 0.8% | 0.01% | -99% |

| Space Utilization | 6m aisle | 2.5×3m | +140% |

Optional Upgrades

| Option | Function | E-commerce Value |

|---|---|---|

| Dual-depth forks | Fork stroke extended to 800mm | Handle 2 totes simultaneously, efficiency↑40% |

| RFID batch scan | Contactless whole-pallet reading | Mis-sort rate↓ to 0.01% |

| Cold storage kit | -25℃ motor + anti-condensation | Cold chain sorting (fresh e-commerce) |

| Digital twin | Real-time 3D monitoring + predictive maintenance | Downtime↓90% |

| Energy recovery | Regenerative braking | Power consumption↓35% (TÜV) |

| Peak buffer deck | Intermediate platform (≥500 tote) | Handle Black Friday surges |