12.11.2025 / 5-minute read

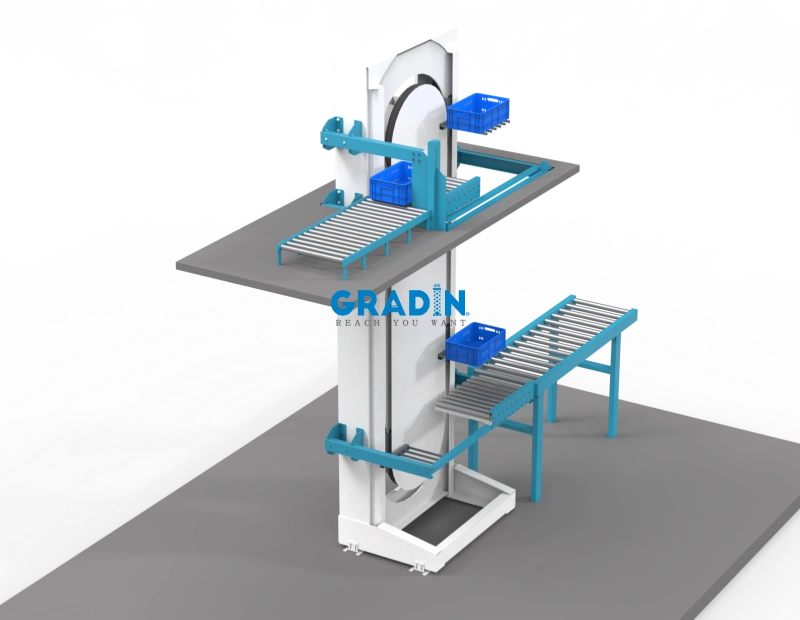

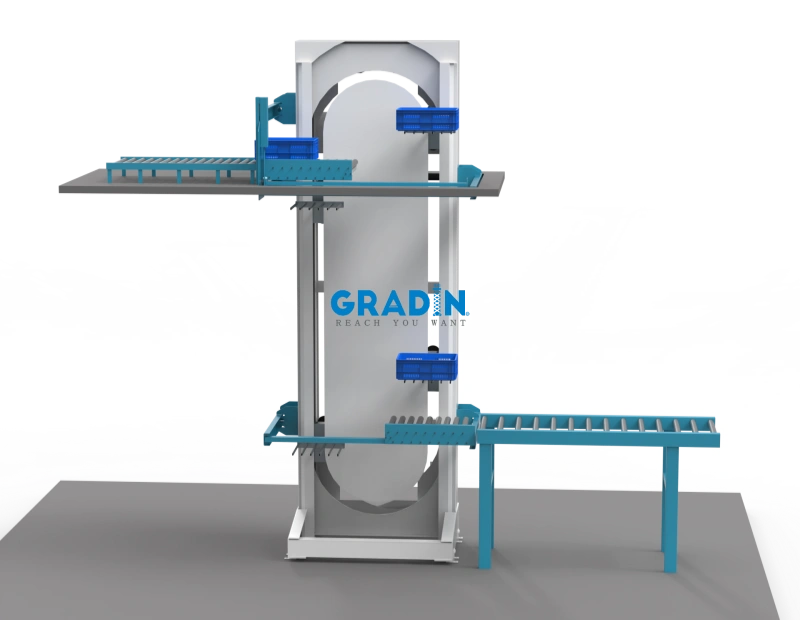

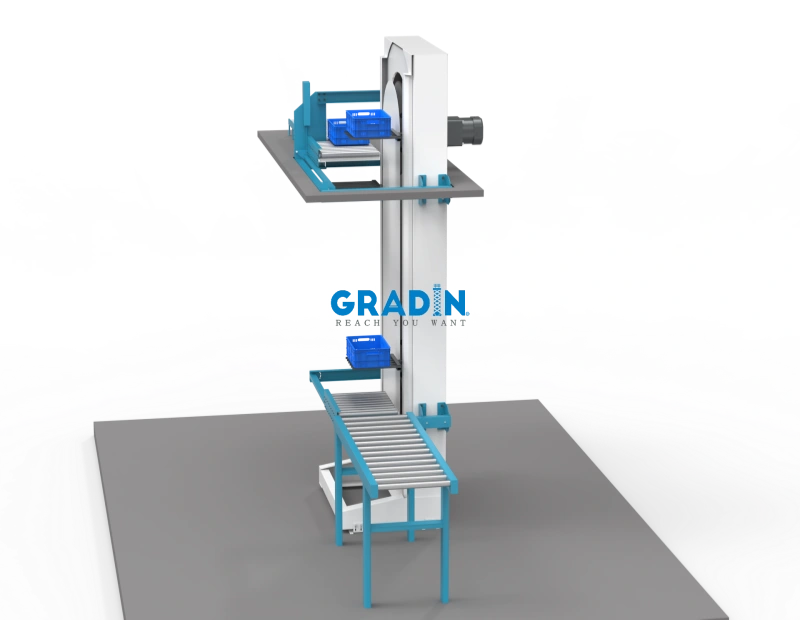

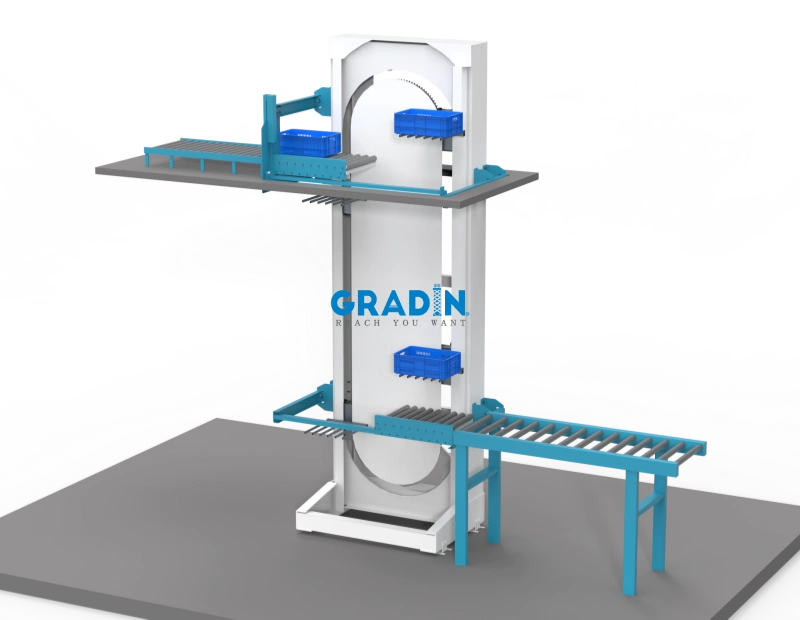

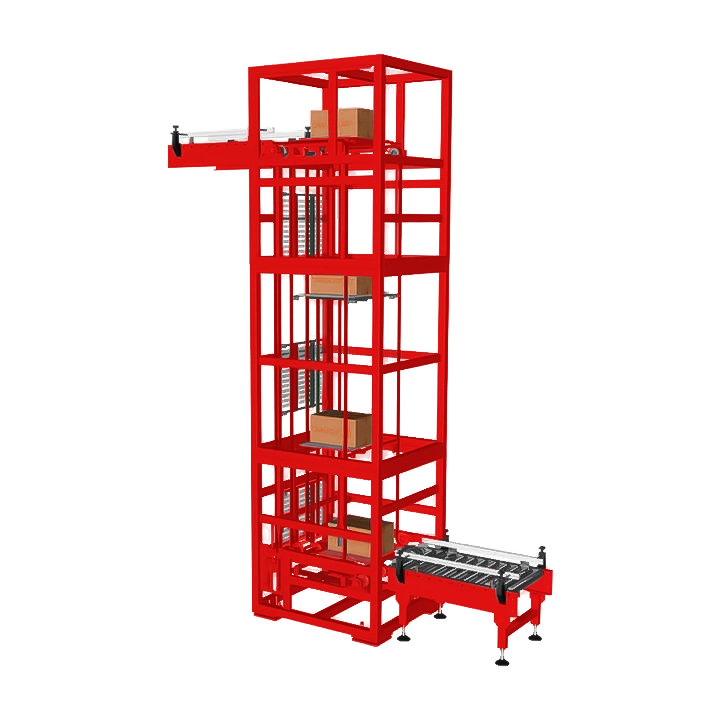

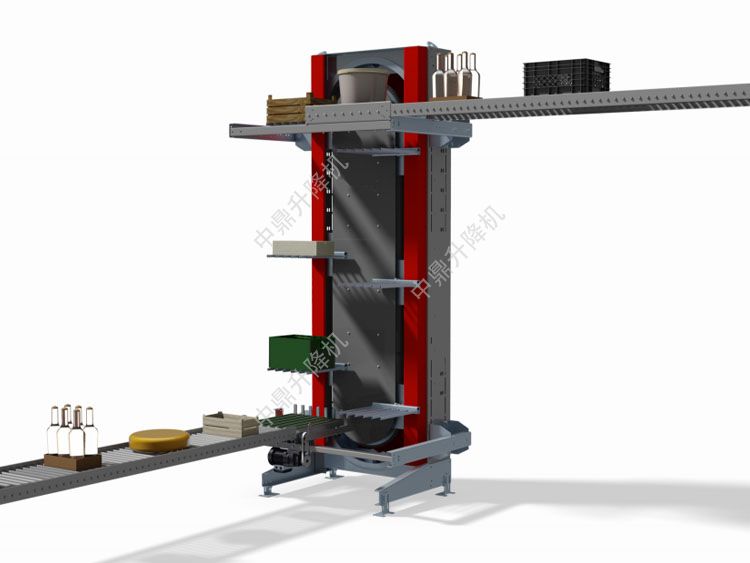

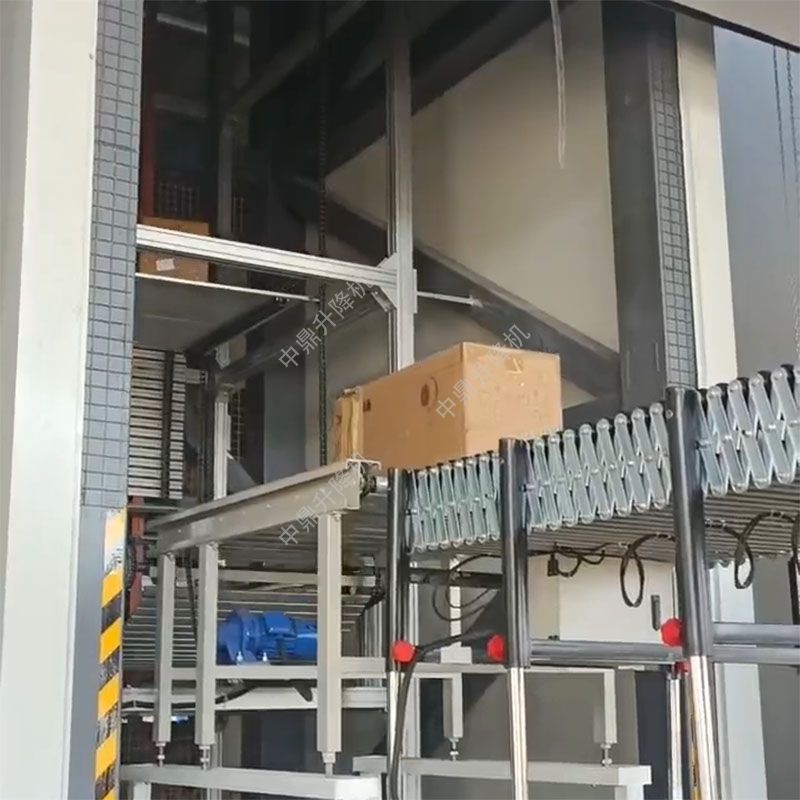

Fork-Arm Continuous Lifter in Automated Battery Pack Handling

Overview

With the explosive growth of the new energy vehicle industry, the production scale and quality requirements for battery packs have surged dramatically.

This plant faced a core challenge: how to safely, efficiently, and cleanly transport battery packs—weighing 300-800 kg, high-value, and requiring cleanliness—in a continuous, automated flow between the first-floor assembly line and the second-floor testing line/buffer storage.

Basic Parameters

| Parameter | Specification | Notes |

|---|---|---|

| Load Capacity | 300 kg / 500 kg / 1000 kg / 2000 kg | Standard options; custom designs available. |

| Lifting Speed | 0.2 – 0.5 m/s | Adjustable via VFD; speed depends on load & height. |

| Positioning Accuracy | ±1 mm | Achieved with servo drive & encoder feedback. |

| Lifting Height | Up to 30 m | Modular design; height determined by floor levels. |

| Carrier Platform Size | (L) 1500-3000 mm x (W) 1200-1800 mm | Customizable to match pallet/jig size. |

| Throughput (Cycles/Hour) | 20 – 60 cycles/h | Depends on height, speed, and load/unload time. |

| Drive System | Servo Motor / AC Motor with Gearbox | Servo for high precision; AC for cost-effective duty. |

| Control System | PLC (Siemens/Allen-Bradley) | Standard HMI; interfaces with MES/WMS via Profinet/Ethernet IP. |

| Safety Features | • Dual electromagnetic brakes • Safety gear/overspeed governor • Light curtain at entrance/exit • Emergency stop buttons • Load weighing system | Complies with relevant machinery safety directives. |

| Operating Environment | Temperature: 0°C to +40°C Humidity: Max. 80% RH (non-condensing) | Stainless steel & special treatment available for harsh conditions. |

| Noise Level | ≤ 70 dB(A) | Measured at 1 meter distance in standard operation. |

| Power Supply | 3-Phase, 380V / 50Hz (or local standard) | Other voltages available upon request. |

Challenge

- High Safety Risk: Reliance on cranes and manual handling posed drop and collision risks, threatening both personnel and valuable products.

- Efficiency Bottleneck: Unstable handling cycles could not match high-speed production lines, creating a choke point.

- Quality Concerns: Manual handling could cause scratches to the battery pack casing or loose connectors; dust control was difficult.

- High Management Cost: Required significant manpower, was labor-intensive, and made real-time logistics tracking challenging.

Solution

- Heavy-Duty Dual Fork-Arm Structure: Employed a synchronously driven dual fork-arm design to ensure absolute stability when handling battery packs up to 1000 kg, eliminating any tilt or sway and fundamentally eradicating safety risks.

- Precision Servo Positioning System: Integrated with the upper-level MES system, achieving positioning accuracy of ±1 mm. This ensured seamless and precise docking with roller conveyors and AGV interfaces for “immediate transfer.”

- Fully Enclosed Cleanroom Design: The entire lift path was sealed, equipped with an ionized air curtain and vertical laminar flow purification system to effectively isolate external dust, meeting the Class 10,000 cleanliness requirement of the battery production area.

- Multi-Layer Safety Protection:

- Redundant mechanical + electromagnetic safety brakes.

- Real-time load weighing system on the platform (overload/underload alarm).

- Light curtains and safety bumpers to ensure personnel and equipment safety.

- Full-process operation monitoring and fault self-diagnosis.