12.3.2025 / 5-minute read

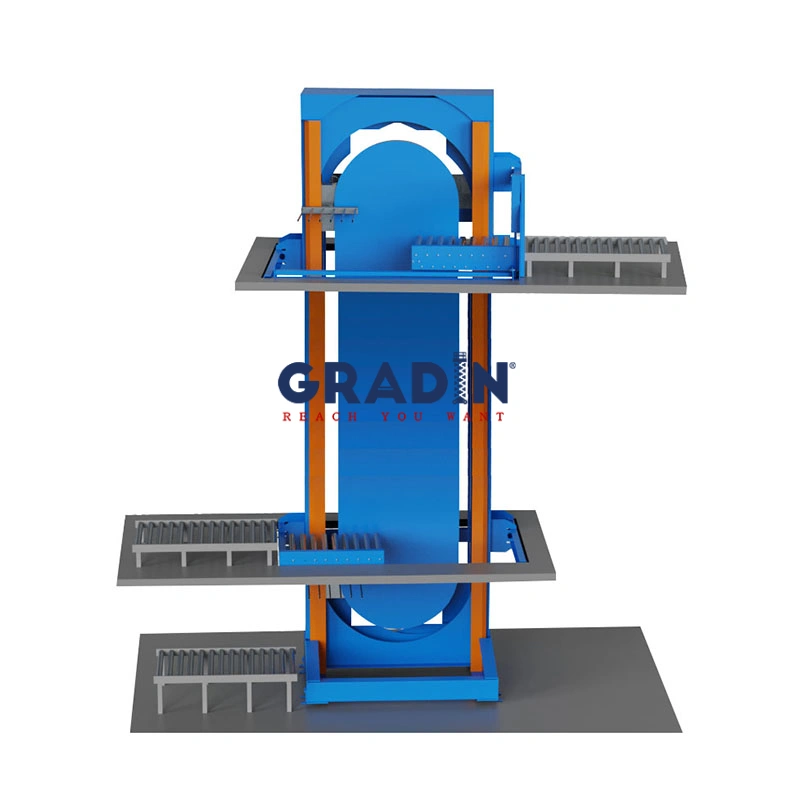

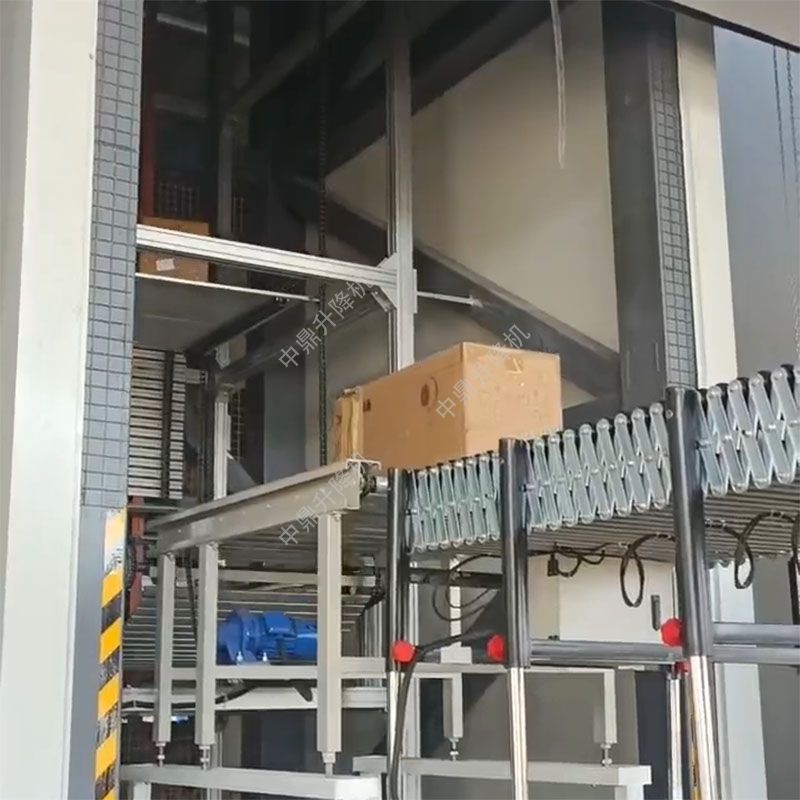

External Vertical Conveyor for Heavy Industry | Continuous Fork Lift

Project Overview

Analyzed through the lens of Challenge – Solution – Parameters – Workflow, the Externally-Mounted Multi-Level Fork Continuous Lifter is not merely a equipment replacement but a breakthrough systemic logistics solution.

By reconfiguring space (internal to external), re-engineering processes (dedicated logistics channel), and automating heavy-load handling, it systematically resolves the multiple contradictions of space, efficiency, safety, and continuity faced by traditional heavy industry in brownfield upgrades.

It is a strategic enabler for “zero-footprint expansion” and “non-stop production renovation.”

Basic Parameters

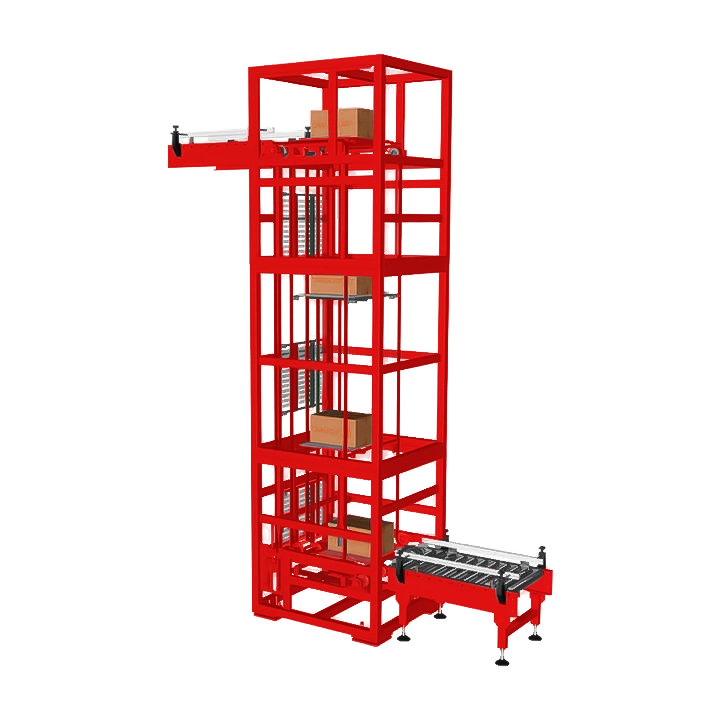

| Way of working | One in and one out | One in, many out | More in and one out | Remark |

| Cargo dimensions(mm) | PL≤500 | PW≤600 | PH≤800 | Maximum overall dimensions(If the size exceeds the size, it needs to be customized.) |

| Maximum weight of product shipped | ≤50Kg | Heavy duty customizable | ||

| Hoist width | 1590 | PL>500,Needs customization | ||

| Hoist length | AL(The length of the elevator for incoming and outgoing materials in direction A) | BL(The length of the elevator for incoming and outgoing materials in direction B) | GL(The length of the bottom of the elevator) | L(Overall length of hoist) |

| AL=1110 | BL=1267 | BL=985 | Import and export are all in direction A=AL+200There is a B side for import and export =BL+200 | |

| Hoist height | H≥CH2+700 | |||

| Stroke height | AH=CH2-CH1 | |||

| Minimum distance between forks | Exit from direction A:DT=PH+PW+500 | Exit from direction B:DT=PH+PL+500 | ||

| Line speed | 10~32 | m/min | ||

| Maximum capacity | S=32000/DT*60 | pieces/hour | ||

| One layer conveying height(mm) | CH1≥700 | Below 700, a pit needs to be dug | ||

| Carrying capacity per square meter | 1500KG | Standard machine (height 3.8 meters) | 1500KG+200KG/M | Add 200KG for every 1 meter increase in height |

| Floor opening size(mm) | L=1250 | W=1270 | Normally | |

| Air consumption | One in, one out: 0 | Multiple inlets and multiple outlets: +400L/min (for each additional inlet or outlet) | ||

| Equipment material | Carbon steel paint, stainless steel | |||

Challenge

- Absolute Space Lock: Production areas and existing storage were saturated, with zero internal space available for a new vertical logistics channel.

- Conflicting Process Flows: Internal transport routes for heavy materials intersected with personnel zones and precision production areas, leading to low efficiency, significant safety hazards, and cross-contamination.

- Zero-Downtime Mandate: Production schedules were full, disallowing any operational shutdown for logistics renovation.

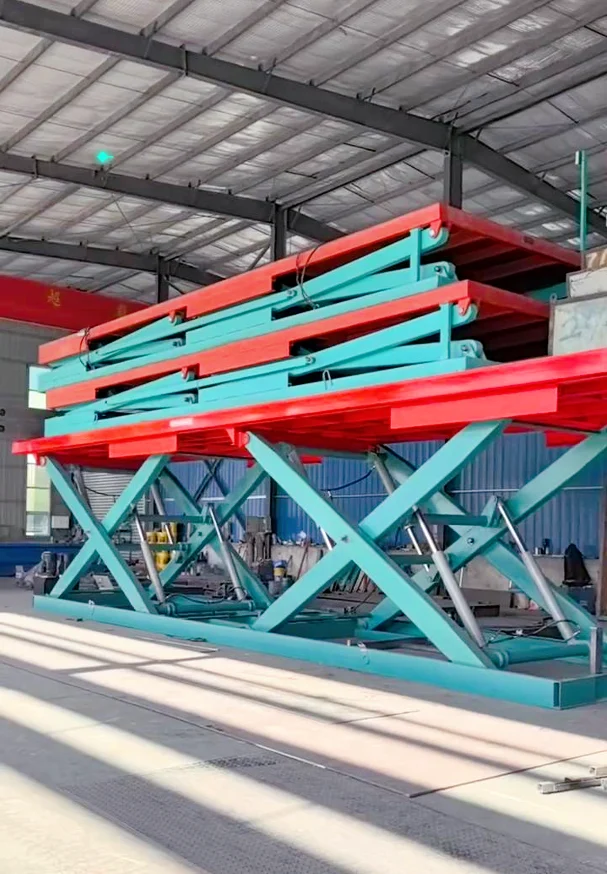

- Demanding Load & Environment: Required handling of single units weighing 10-30 metric tons (e.g., metal components, large raw material modules) in an environment with dust, temperature variations, and other industrial challenges.

Workflow

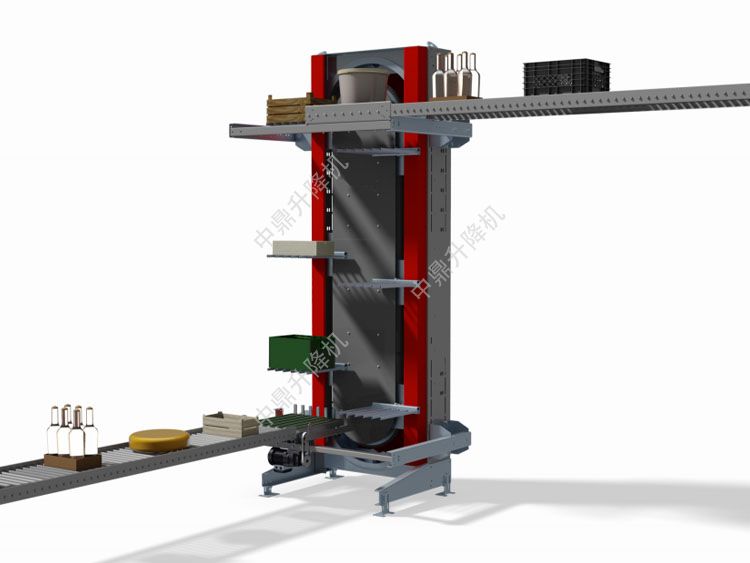

- Platform & Enclosure: The platform was finished with a 304-grade stainless steel, non-slip floor for easy cleaning and food safety compliance. A hygienic, powder-coated enclosure with clear viewing panels was added for safety and load verification.

- Drive System & Control: The system utilizes a powerful yet smooth AC electric drive (configured for 220V), offering quiet operation essential for a hotel environment. The Programmable Logic Controller (PLC) was programmed with multiple stop points and access codes. For instance, the basement loading dock has unrestricted access, while upper-floor discharge points require key-switch activation, ensuring security and controlled access to supplies.

- Safety & Reliability: It features elevator-grade guide rails for exceptionally smooth and stable travel, along with multiple safety interlocks, gate sensors, and overload protection, ensuring complete compliance with material handling safety standards.