7.4.2025 / 6-minute read

Drum Continuous Lift | Automated Heavy-Duty Drum Lifting Solution

Overview

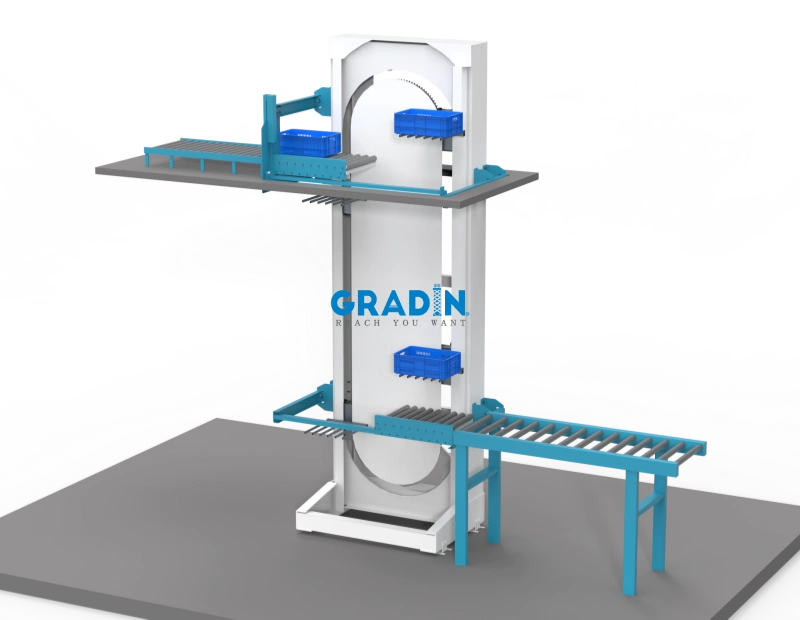

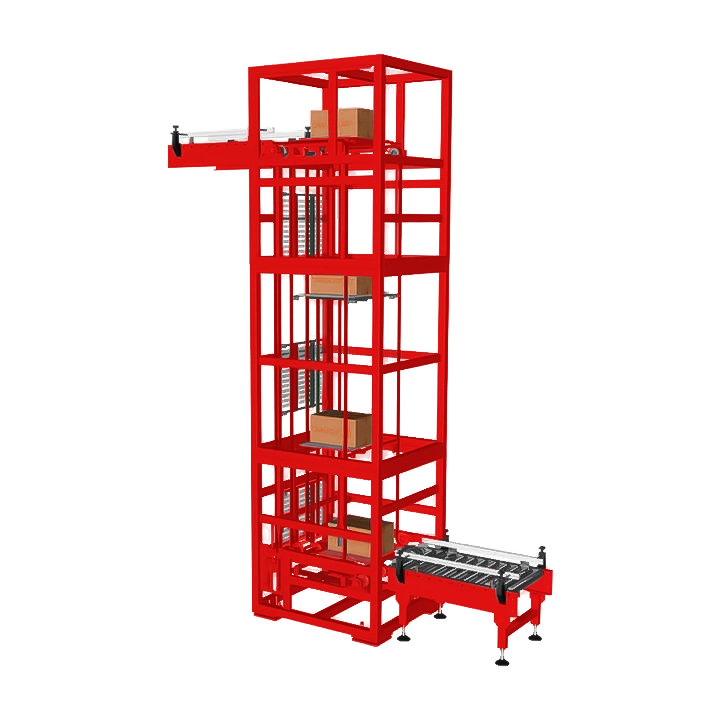

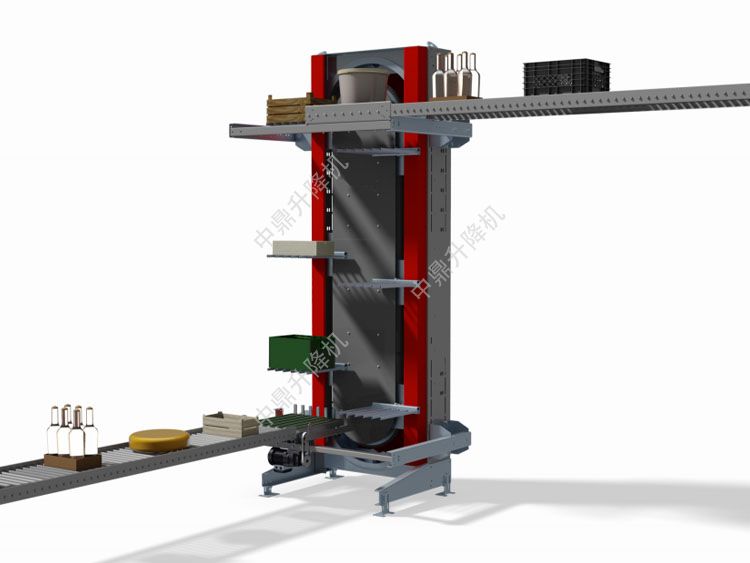

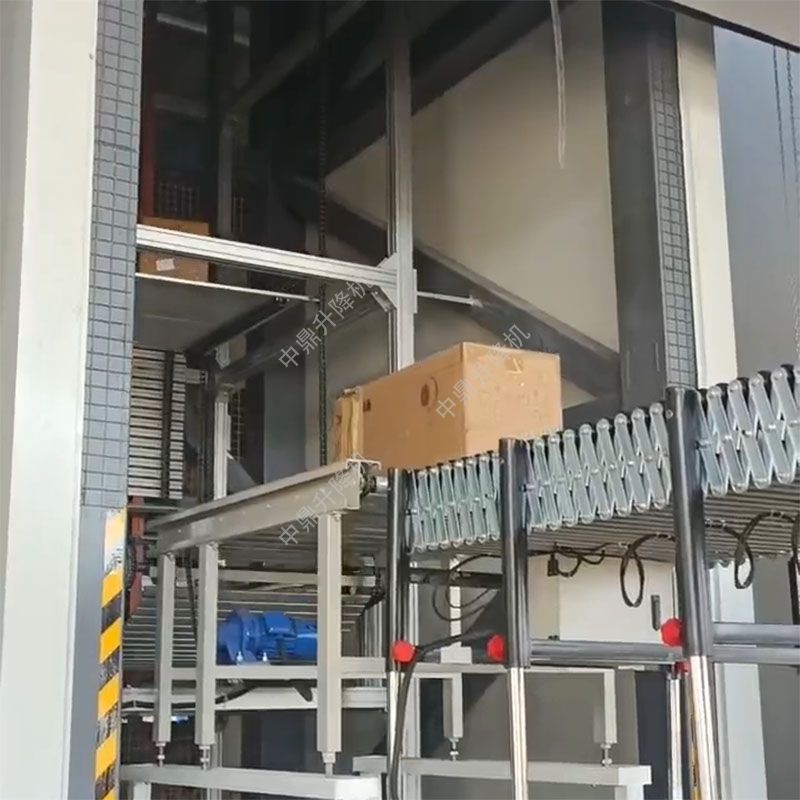

A continuous, automated lifting system specifically engineered for the efficient and safe elevation and transfer of standard drums (55-gallon / 200-liter).

Ideal for production lines, warehouse loading/unloading, filling lines, etc., significantly boosting material handling efficiency while reducing labor costs and risks.

Basic Parameters

| Parameter | Specification Range | Units | Notes |

|---|---|---|---|

| Load Capacity | 150 – 500 | kg (per lift) | Single or multiple drums |

| 330 – 1100 | lbs | ||

| Lift Height | 1 – 10+ | m | Customizable |

| 3.3 – 33+ | ft | ||

| Lifting Speed | 0.1 – 0.5 | m/s | Adjustable |

| 0.33 – 1.64 | ft/s | ||

| Drum Compatibility | Ø 560 – 600 | mm | Standard 55-gal drums |

| (Diameter) | Ø 22 – 24 | in | |

| Drive System | Electric / Hydraulic | — | 3-phase motor standard |

| Control System | Push Button / PLC + HMI | — | Optional automation |

| Power Supply | 380-480V / 50-60Hz | — | Hydraulic: 15-25 bar |

| (220-360 PSI) | |||

| Operating Temp. | -10°C to +50°C | °C | Industrial standard |

| 14°F to 122°F | °F | ||

| Noise Level | < 75 | dB(A) | At 1 m distance |

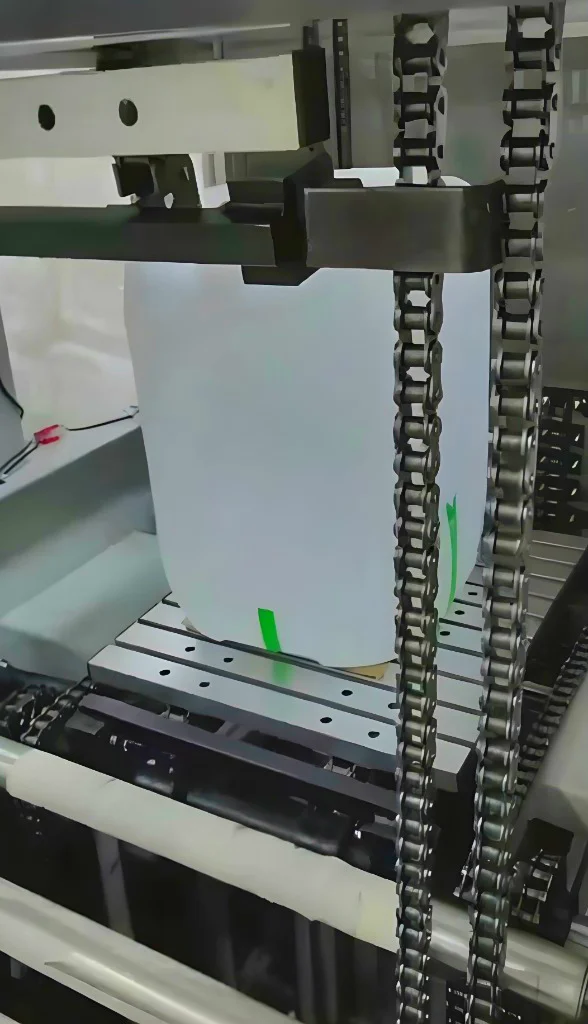

Working Principle

Utilizes a chain or belt-driven system equipped with specialized drum clamps or platforms. Drums are automatically fed into the lift inlet, continuously and smoothly elevated (or lowered) to the designated height by the conveying system, and automatically disengaged/released at the outlet, enabling continuous vertical transportation of drummed materials.

Technical Advantages

- Continuous Operation: Seamlessly integrates with upstream/downstream processes for uninterrupted material flow.

- High Efficiency & Stability: Fast lifting speed, high load capacity (single or multiple drums), smooth and shock-free operation.

- Drum-Specific Tooling: Features adaptive drum clamps, slots, or platforms to securely grip standard drums (full/empty), preventing slippage and tipping.

- Safety & Reliability: Multiple safety protections (overload protection, emergency stop, anti-drop device, safety guards/light curtains), compliant with industrial safety standards.

- Robust Construction: Built from heavy-duty steel for durability in industrial environments.

- Easy Integration: Flexible interfacing with conveyors, filling machines, palletizers, etc., for automated production lines.

- Easy Maintenance: Modular design facilitates access and replacement of key components

Compatible Drum Types

- Standard 55-gallon / 200-liter steel drums, plastic drums (subject to chime configuration verification).

- Customizable for other drum specifications

Typical Applications

- Chemical: Hazardous material transfer

- Pharmaceutical: GMP packaging handling

- Electronics: ESD-sensitive component

- Warehousing: Narrow-aisle AS/RS feeding

Core Benefits

- Dramatically increases handling efficiency, reducing labor dependency and cost.

- Maximizes operator safety, minimizing injury risks.

- Protects drums and contents from handling damage.

- Optimizes space utilization by enabling vertical material flow.

- Enhances production automation and intelligence

Customization Options

- Lift height, speed, load capacity customization.

- Inlet/Outlet height and direction customization.

- Gripper customization for special drums or closures.

- Versions for explosive atmospheres (ATEX), cleanrooms, etc.

- Control system integration (PLC, HMI).