9.5.2025 / 6-minute read

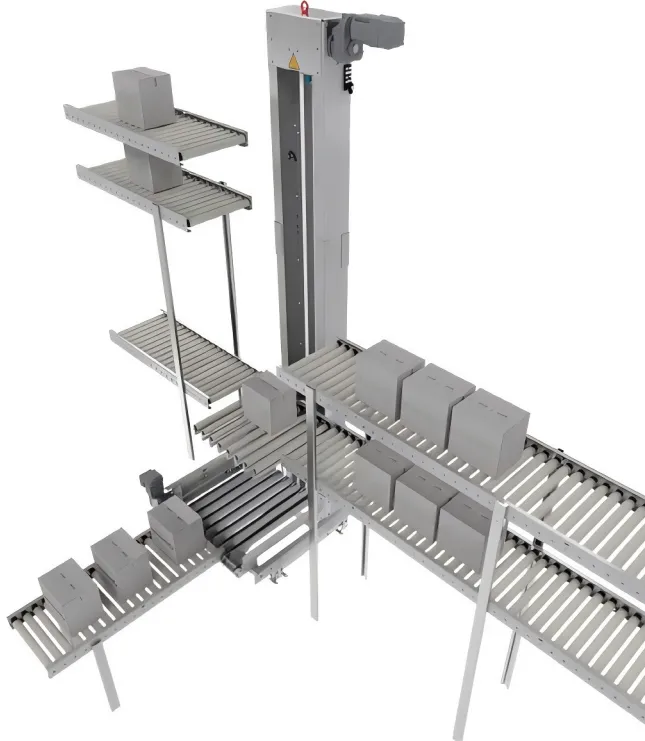

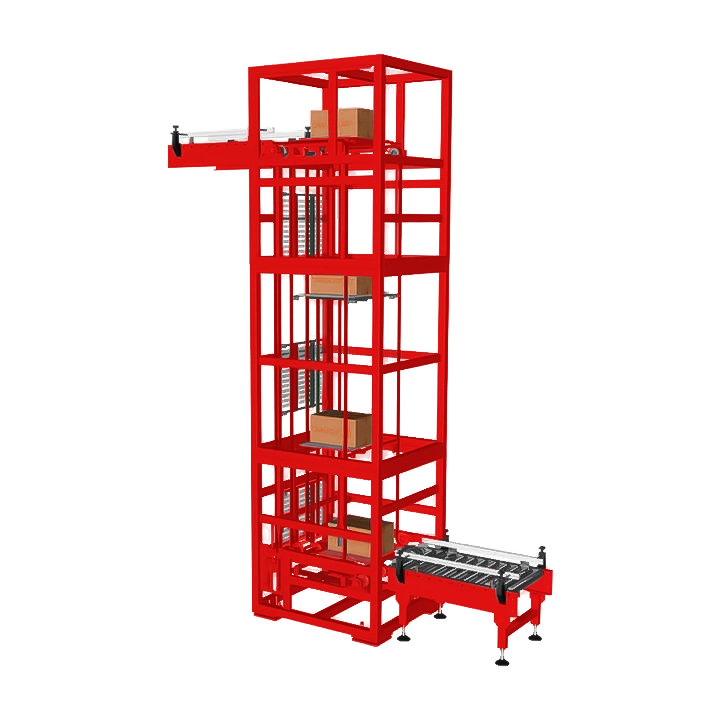

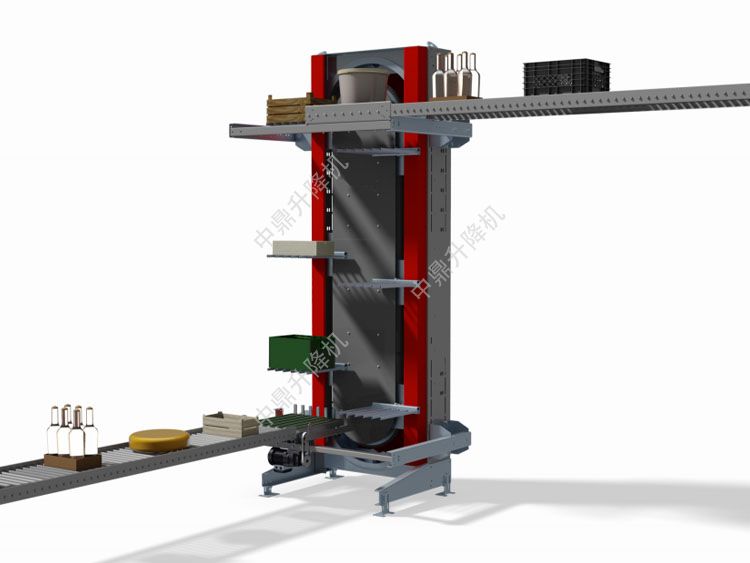

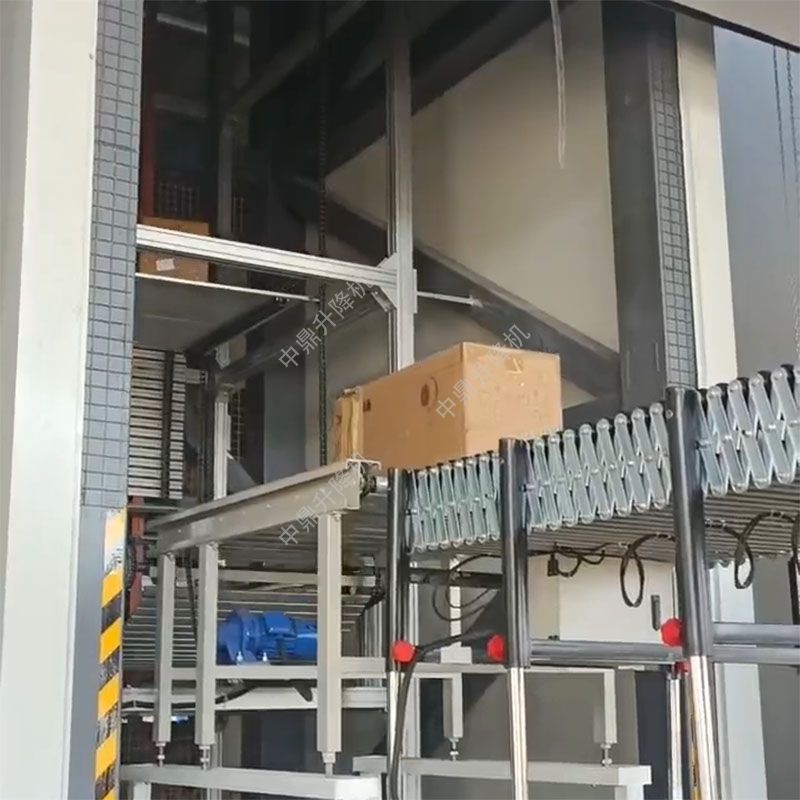

Compact Single-Mast Continuous Lifter – Professional Vertical Handling Solution

Overview

This case analysis presents the compact single-mast continuous lifting platform.

As a leading provider of vertical transportation solutions, Gradin designed this equipment specifically for space-constrained industrial environments.

Our product demonstrates Gradin’s technical expertise in material handling and has been successfully implemented across various industries.

Basic Parameters

| Parameter | Value/Specification |

|---|---|

| Min. In/Out Height | 360 mm |

| Max. In/Out Height | 14,300 mm |

| Max. Travel Height | 14,450 mm |

| Max. Load Capacity | 100 kg |

| Max. Item Size | 910 × 610 mm |

| Max. Capacity | 360 cycles/hour |

| Direction Options | Left/Right/Front |

| Drive System | Gradin Quiet Belt Drive |

How It Works

The Gradin lifting system utilizes our proprietary belt-driven mechanism for continuous vertical transportation.

Materials are loaded onto the carrying platform and automatically elevated to the required height through Gradin’s advanced control system.

Our modular design supports multiple intake/discharge directions, featuring Gradin-manufactured roller conveyors that ensure seamless integration with existing systems.

The Challenges

- Space constraints limiting equipment installation

- Need for continuous vertical material transfer

- High noise levels and maintenance requirements

- Requirement for flexible material handling

- Integration needs with existing systems

Solutions

- Space-saving Design: Our compact single-mast structure

- High Efficiency: 360 cycles/hour handling capacity

- Quiet Operation: Gradin’s exclusive belt drive technology

- Modular Flexibility: Customizable directions and heights

- Seamless Integration: Gradin roller conveyors for system compatibility

- Versatile Application: Multiple configuration options