9.17.2025 / 5-minute read

Aerospace High-Precision Mechanical Lifting Platform for Aircraft Engine Maintenance & Wind Tunnel Testing

Overview

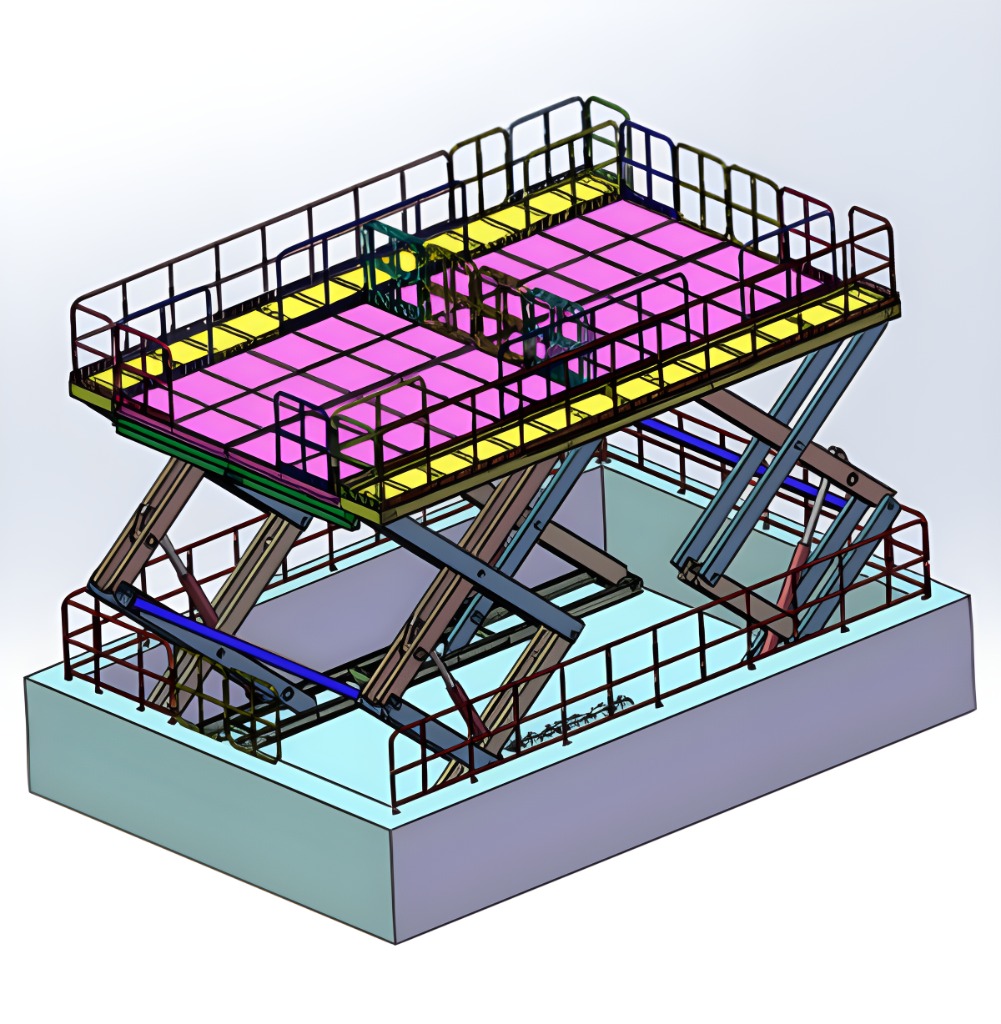

This case analysis details a high-precision mechanical lifting platform custom-developed for the aerospace industry’s specific requirements.

Designed for aircraft engine manufacturers and aircraft manufacturing maintenance, it achieves millimeter-level precision lifting through advanced mechanical structures and control systems, meeting the extreme demands for safety and accuracy in aerospace applications.

Basic Parameters

| Parameter | Technical Specification |

|---|---|

| Positioning Accuracy | ±0.5mm |

| Lifting Speed | 0.1-5m/min (stepless adjustable) |

| Platform Flatness | ≤1mm/m² |

| Protection Rating | IP65 (dust and water resistant) |

| Control System | Multi-axis synchronous servo control |

| Safety Devices | Dual redundant safety locking + fall protection |

| Material Standard | Aerospace-grade aluminum/stainless steel |

| Temperature Range | -20℃ to +50℃ operational range |

How It Works

The equipment employs precision mechanical transmission systems and advanced servo control technology, achieving precise and smooth platform movement through multi-axis synchronous control.

Equipped with platform access ladders, safety belt connection points, and detachable handrails, operators control the lifting process through a user-friendly interface while the system monitors load and position status in real-time, ensuring absolute safety during critical operations.

The Challenges

The aerospace sector confronts unique challenges in equipment maintenance and manufacturing:

- Maintenance of aircraft engines and critical components requires millimeter-level positioning accuracy.

- Extreme equipment stability and reliability are essential for specialized environments like wind tunnel testing.

- Stringent safety standards necessitate multiple, redundant safety mechanisms.

- Diverse aircraft types and operational scenarios demand highly customized solutions.

- Equipment must perform reliably under the unique environmental conditions of aerospace applications.

Solutions

- Ultimate Precision Control: A multi-axis synchronous servo system ensures ±0.5mm positioning accuracy.

- Comprehensive Safety: Dual redundant safety systems, fall protection, and integrated safety connection points create multiple layers of security.

- High Customizability: The design supports various configurations, including U-type scissor platforms, to accommodate different aircraft models.

- Aerospace-Grade Materials: Construction utilizes aerospace aluminum and stainless steel for an optimal combination of lightweight properties and durability.

- Intelligent Control System: A user-friendly interface streamlines operations and enhances workflow efficiency.

- Environmental Resilience: A wide operational temperature range ensures performance across diverse aerospace environments.