10.31.2025 / 5-minute read

5-Stop Vertical Lift | For Constrained Spaces & Heavy Loads

Overview

We design and build a specialized industrial lift for a critical logistics upgrade at the Fire Headquarters. The project required a reliable, high-capacity vertical transport solution to efficiently move goods across five floors, supporting the facility’s operational readiness.

We combine detailed spatial planning with practical foresight in our electrical designs, providing clients with a system that not only meets their immediate needs but is also prepared for future expansion. If your facility requires a reliable and efficient material handling lift, contact us to discuss a tailored solution.

Basic Parameters

| Parameter Category | Specification |

|---|---|

| Car Dimensions | L1800 × W1500 × H2200 mm |

| Cargo Pallet Size | W1000 × D1200 mm |

| Pit Size (External) | 2500 × 2200 mm (2500 direction for loading/unloading) |

| Internal Window Width | 1800 mm |

| Travel Height | 18.1 m (1F-2F: 5.5m, 2F-5F: 4.2m each) |

| Rated Load Capacity | 1 Ton |

| Stops & Stations | 5 Stops, 5 Stations |

| Loading/Unloading Mode | Through-and-through |

| Lifting Speed | ≥ 30 m/min |

| Pit Depth | 0.5 m |

| Loading/Unloading Opening | 1500 mm (Through-and-through) |

Challenges

- Multi-Floor Logistics: The need for a reliable system to transport goods (up to 1000 kg) efficiently across five different floors, with varying floor heights.

- Spatial and Access Constraints: The installation was constrained by a specific pit size (2500*2200mm) and a narrow interior window opening (1800mm width), requiring a precise and compact design.

- Through-Flow Efficiency: The operation required a “through-and-through” loading/unloading design (1500mm clear opening) to streamline workflow and minimize turnaround time.

- Future-Proofing: The client needed a system that could be easily integrated with future access control or door systems without requiring major electrical modifications later.

Our Solution

- Robust Structural Design: The lift was built with a heavy-duty F120 frame and J100*50*4mm connectors, ensuring stability over an 18.1-meter travel height. The car guide rails (T90) and counterweight guides (TA5A) guarantee smooth and aligned operation.

- High-Capacity & Efficient Drive: Utilizing a reliable 20A double-chain conveyor mechanism, the system provides a lifting speed of ≥30 m/min, balancing speed with operational safety and stability.

- Precision Engineering for Space Constraints:

- The car’s external footprint of 1500x1500mm was optimized for the available pit and window access.

- The internal cargo platform (1000x1200mm) within the 1800x1500x2200mm car provides ample space for palletized goods.

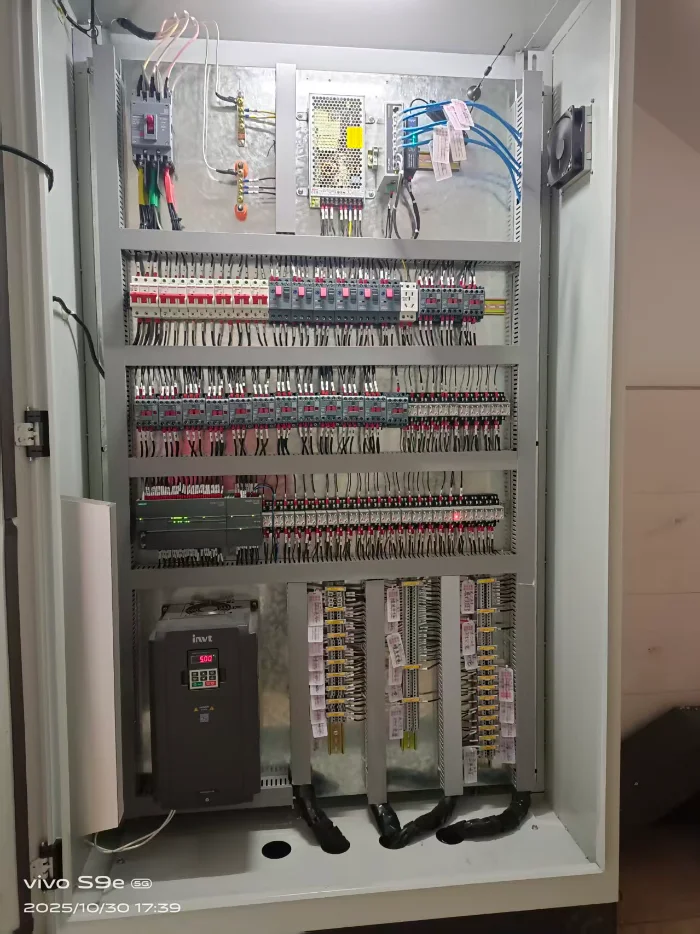

- Future-Ready Control System:

- The control system was pre-equipped with all necessary logic and interfaces for future leveling and door interlock functions. This foresight allows for seamless integration of access doors later, without costly electrical rework.

- Durable Finish: The equipment was finished in a standard blue color, as per the client’s specification, providing a professional appearance.