11.14.2025 / 5-minute read

3-Way Mobile Lift for Spray Booths | Explosion-Proof

Project Overview

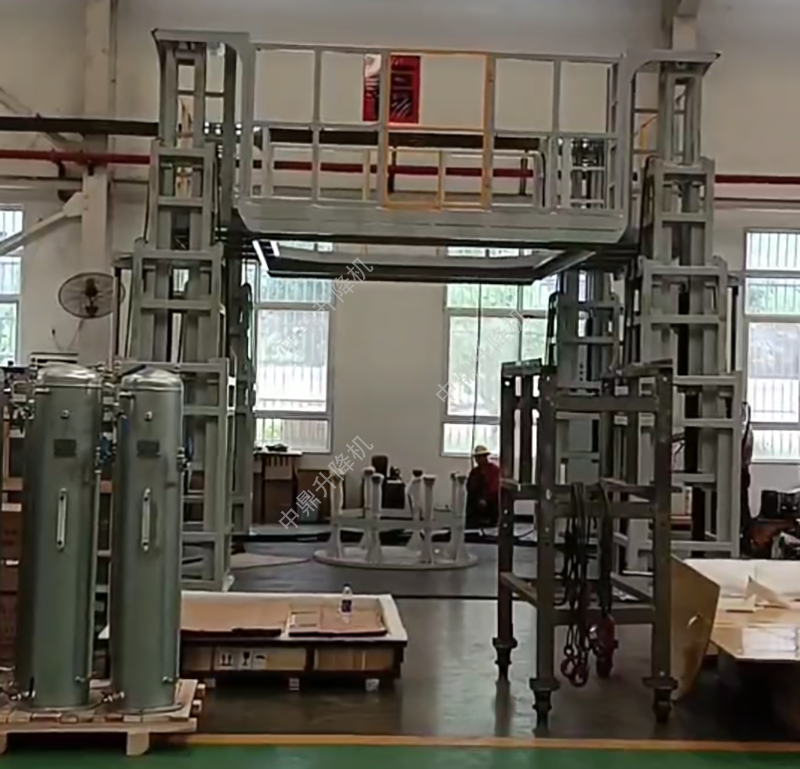

This case study details the application of the Gradin 3D Mobile Lifting Platform within an industrial spray finishing environment.

The primary challenge was to improve the safety and ergonomics of painting large, heavy objects (e.g., vehicle bodies, industrial machinery) while maximizing workflow efficiency.

Traditional fixed-position lifts or scaffolding were inflexible and posed significant safety risks in explosive atmospheres.

The Gradin solution—a 3-direction mobile, explosion-proof scissor lift—provided a transformative approach by enabling precise, safe, and stable positioning of the workpiece, leading to a demonstrable reduction in operational risks, a significant improvement in paint job quality, and a faster turnaround time.

Basic Parameters

| Category | Specification |

|---|---|

| Product Model | Gradin 3D Spray Booth Series |

| Brand | Gradin |

| Platform Self-Weight | 2500 kg |

| Rated Load Capacity | 300kg |

| Platform Dimensions (Typical) | Customizable (e.g., to fit specific workpiece sizes) |

| Minimum Height | 500 mm |

| Lifting Speed | 6 m/min |

| Drive Method | Hydraulic |

| Motor Power | 1.5 KW |

| Power Supply | 220V / 380V (Global Standard) |

| Control System | Explosion-Proof with Digital Display & Emergency Stop |

| Key Feature | Three-Directional Mobility (Forward/Backward, Left/Right, Up/Down) |

| Frame Material | High-Quality I-Beam Steel |

| Availability | Global |

| Customization | Available |

The Challenges

- Fixed Work Position & Worker Fatigue: Static scaffolds or lifts force painters to constantly move around the object, leading to inconsistent application, fatigue, and potential quality issues with complex geometries.

- Safety Hazards in Explosive Atmospheres: Standard electrical equipment (motors, controls) can generate sparks, posing a severe explosion risk in environments saturated with flammable paint particles and vapors.

- Lack of Precision Positioning: Maneuvering heavy objects into the perfect ergonomic position for overhead or detailed work is difficult, slow, and often requires multiple operators.

- Inefficient Workflow: The inability to easily move the workpiece in and out of the booth or between stations creates bottlenecks, slowing down the entire production line.

Solution

- 3-Directional Mobility for Unmatched Ergonomics:

- The platform moves laterally, longitudinally, and vertically. This allows operators to position the workpiece perfectly without straining, ensuring a consistent distance to the surface and enabling high-quality, uniform coating application from a comfortable, fixed stance.

- Comprehensive Explosion-Proof System for Intrinsic Safety:

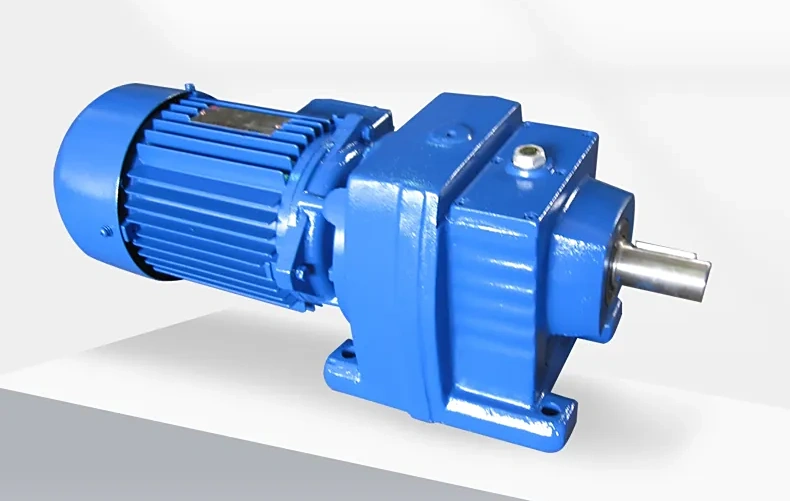

- Explosion-Proof Motor & Control System: All electrical components are housed in certified enclosures that prevent internal sparks from igniting the external atmosphere.

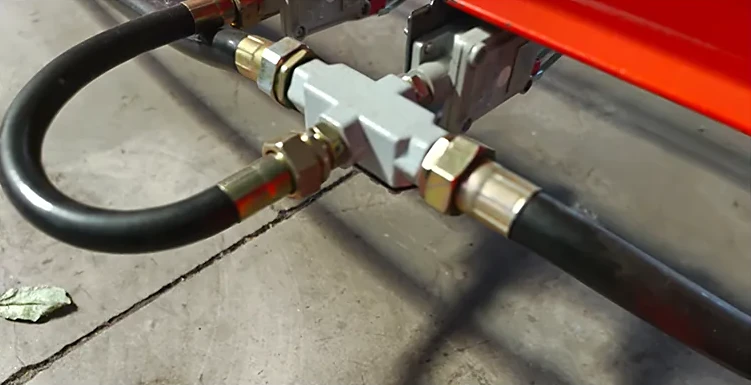

- Power-Off Protection: Integrated emergency stop and brake systems engage immediately upon power loss, securely locking the platform in place and preventing accidental movement or descent.

- Heavy-Duty Construction for Reliable Performance:

- Industrial-Grade Load Chains: Designed for high tensile strength and durability, ensuring smooth, reliable lifting without the risk of elongation or failure under heavy, dynamic loads.

- Reinforced Hydraulic Cylinder: The solid piston rod is superior to hollow rods, providing maximum resistance to buckling and bending under heavy, off-center loads, guaranteeing long-term sealing integrity and lifting stability.

- I-Beam Steel Frame & Reinforced Platform: The primary structure uses high-quality I-beams for optimal strength-to-weight ratio. The thickened platform surface, built with channel steel, resists permanent deformation, ensuring a stable, level base for valuable assets.

Details

full view

full view full view

full view full view

full view chain

chain Explosion-proof motor

Explosion-proof motor High-quality steel

High-quality steel Main control cabinet

Main control cabinet Reinforced cylinder

Reinforced cylinder Reinforced platform

Reinforced platform