11.11.2025 / 4-minute read

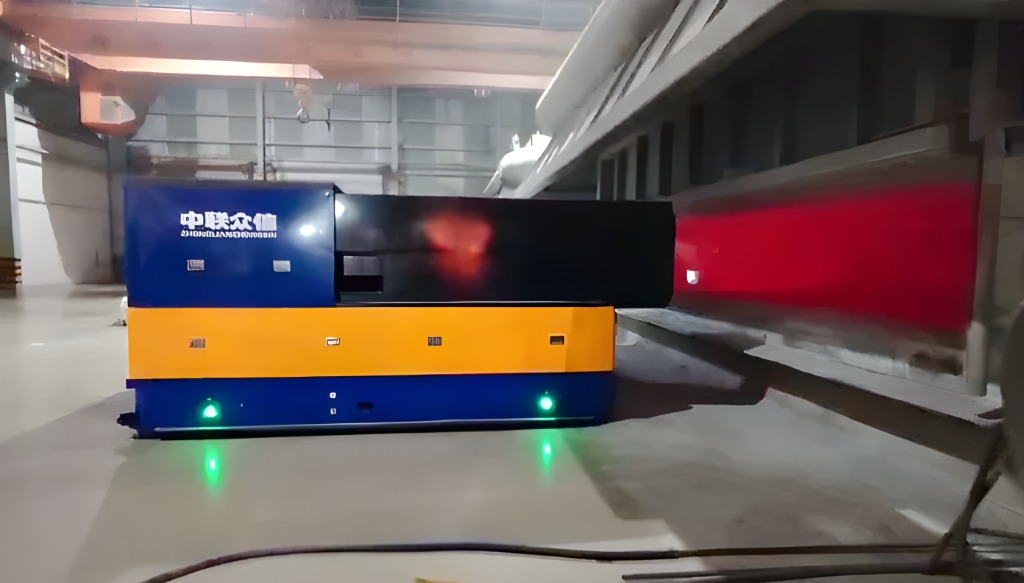

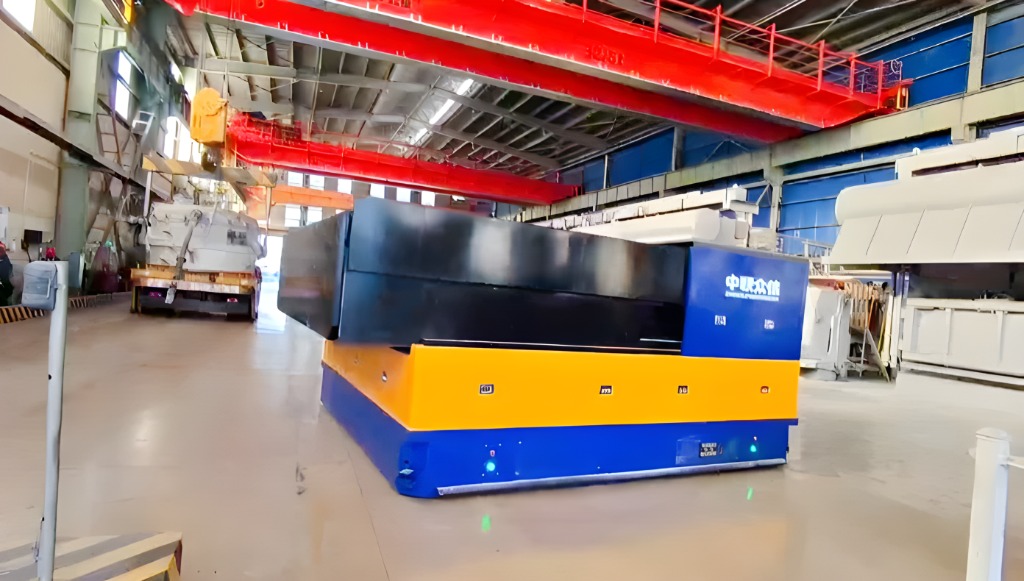

20T Heavy-Duty AGV for Aluminum Industry | Laser Navigation & Auto Charging

Project Overview

Industry: Non-ferrous Metals / Aluminum Manufacturing

Project Timeline: Full lifecycle support from production to 1-year warranty

Core Challenge: To automate the transport of heavy raw materials and finished products within the aluminum processing facility, requiring extreme precision and reliability under massive 20-ton loads.

Basic Parameters

| Parameter | Specification |

|---|---|

| Load Capacity | 20,000 kg |

| Navigation | Laser + Magnetic Strip Hybrid |

| Drive System | 4 Steering Wheel Units |

| Maneuverability | Omnidirectional (0mm turning radius) |

| Positioning Accuracy | ±30mm |

| Operating Speed | 0-25 m/min |

| Battery System | 72V/300Ah LiFePO4 (8+ hours runtime) |

| Charging | Automatic + Manual Charging Stations |

The Challenges

- Extreme Load Requirements: Transporting 20-ton loads of aluminum materials through busy industrial pathways.

- Precision Positioning: Achieving ±30mm navigation accuracy while carrying these massive loads.

- Continuous Operation: Maintaining 8+ hours of uninterrupted operation in a demanding production environment.

- Complex Navigation: Maneuvering through tight industrial spaces with full omnidirectional capability.

Solution

- Zero-Turn Maneuverability: The 4-wheel steering system enables spot turns and lateral movement, crucial for navigating cramped industrial layouts and making precise adjustments in confined spaces.

- Hybrid Navigation Precision: Laser and magnetic guidance combine to deliver reliable ±30mm positioning even under maximum load, ensuring accurate docking and material placement.

- Industrial-Grade Endurance: The 72V/300Ah LiFePO4 battery system supports full-shift operation with automatic opportunity charging, designed for continuous, high-intensity operation.

- Heavy-Duty Structural Integrity: The chassis and load-bearing components are engineered with high-strength materials to withstand the constant stress of 20-ton loads and ensure long-term structural stability.

- All-Weather Operational Reliability: Key components feature enhanced sealing and protection to perform reliably in industrial environments with dust, moisture, and temperature variations common in metal plants.

- Intelligent Fleet Management Interface: The system is designed for seamless integration with upper-level management systems (MES/WMS), enabling centralized scheduling, traffic control, and real-time operational data monitoring.

- Multi-Layer Safety Protocol: Beyond basic obstacle detection, the system incorporates safety scanners, physical emergency stops, and audible/visual alarms, creating a comprehensive safety cocoon for operation alongside personnel and other equipment.

- Adaptive Ground Clearance & Suspension: The design accounts for minor floor irregularities common in industrial settings, ensuring stable load transfer and maintaining navigation accuracy without requiring perfect floor conditions.

- Fast-Response Technical Support System: Includes remote diagnostics capabilities and a 1-year warranty with readily available spare parts, minimizing potential downtime and ensuring rapid response to any operational issues.