11.13.2025 / 4-minute read

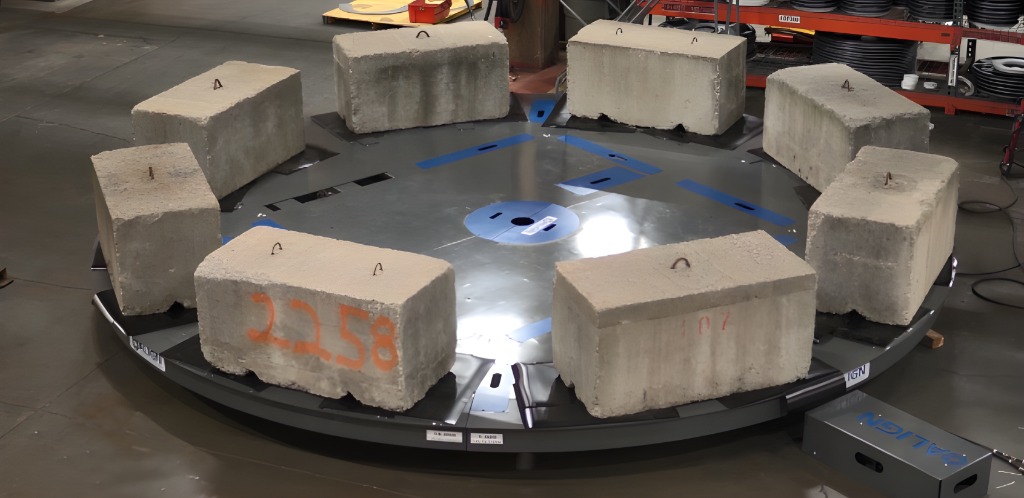

2-Meter Heavy-Duty Turntable for Wind Turbine Blade Manufacturing | Large Component Positioning

Project Overview

Client: Wind Turbine Blade Manufacturer

Industry: Renewable Energy Equipment Manufacturing

Application: Wind Turbine Blade Root Section Processing

Core Challenge: To enable precise positioning and rotation of large blade root sections (Ø2000mm) during machining and inspection processes, requiring exceptional stability and load capacity.

Basic Parameters

| Parameter | Specification |

|---|---|

| Table Diameter | 2,000 mm |

| Load Capacity | 20,000 kg |

| Positioning Accuracy | ±0.1° |

| Drive System | Helical gear drive with servo motor |

| Max. Rotation Speed | 2 RPM |

| Table Flatness | ±0.1 mm/m² |

| Control Interface | PLC with PROFINET connectivity |

| Safety Systems | Emergency stop, mechanical brake, overload protection |

The Challenges

- Oversized Component Handling: Traditional methods couldn’t safely rotate 2-meter-diameter blade root sections

- Precision Machining Requirements: Required accurate angular positioning for drilling and surface treatment operations

- Workplace Safety Concerns: Manual handling of heavy components posed serious safety risks

- Process Integration: Needed seamless integration with existing machining centers and inspection equipment

Solution

- Eliminated Manual Handling: Removed safety risks associated with rotating heavy components manually

- Improved Machining Accuracy: Precision positioning reduced machining errors by 60%

- Enhanced Throughput: 40% faster positioning compared to previous methods

- Reduced Damage: Elimination of handling damage decreased material waste by 25%

- Process Standardization: Enabled standardized positioning across multiple manufacturing stages

- Quality Assurance: Consistent positioning improved final product quality and reliability

- Future-Proof Design: Scalable solution accommodates next-generation larger turbine components