6.25.2025 / 6-minute read

0.8x1m Galvanized Reciprocating Lift | 6m High-Efficiency Vertical Transfer Galvanized Reciprocating Lift | 6m High-Efficiency Vertical Transfer

Project Overview

This project addressed the need for automated, efficient, and reliable material transfer between different production floor levels or workstations at varying heights.

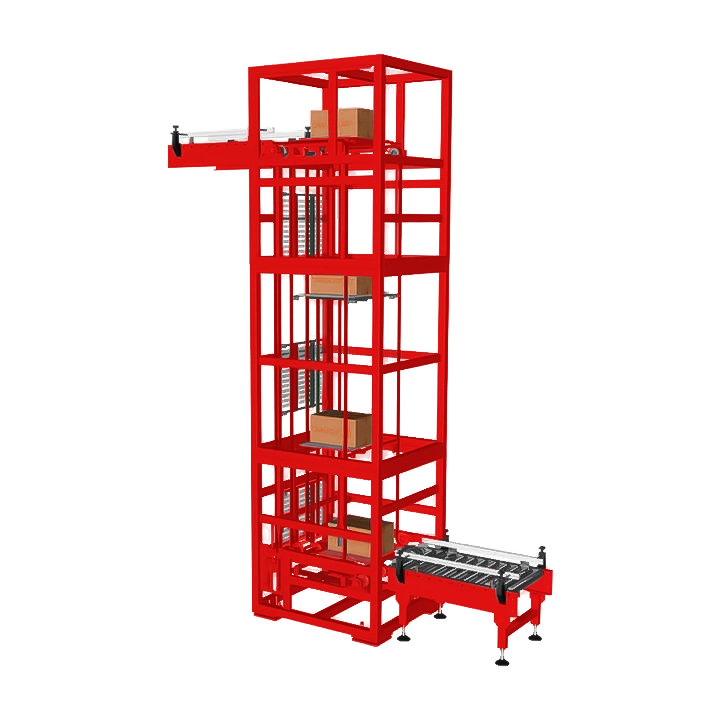

The core equipment is a reciprocating lift with a platform size of 800mm (W) x 1000mm (D) and a maximum lifting height of 6 meters. The lift features galvanized treatment, providing excellent rust and corrosion resistance, particularly suited for industrial environments.

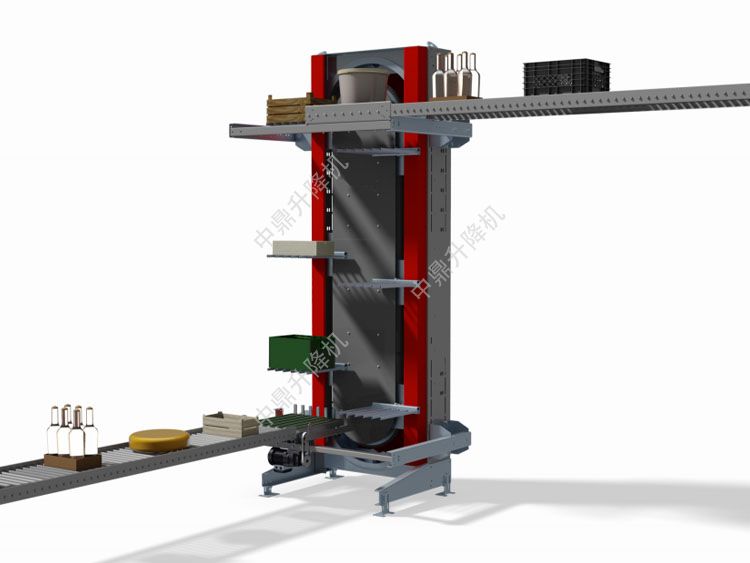

Its critical function is to achieve precise and smooth material handover with roller conveyors at the same or target level, enabling continuous, automated material flow. This eliminates manual handling bottlenecks and enhances production efficiency and logistics automation.

Basic Parameters

| Parameter | Value / Description | Notes |

|---|---|---|

| Equipment Type | Reciprocating Lift | Twin/Four-Post, Platform cycles vertically |

| Platform Size (W x D) | 800 mm x 1000 mm | Effective load-bearing area |

| Max. Lifting Height | 6000 mm (6 meters) | Travel from lowest to highest point |

| Load Handling Method | Platform Loading | Material placed directly on platform or pallet |

| Integration Device | Roller Conveyor | Requires height and position matching |

| Operating Speed | Customizable (e.g., 0.1 – 0.3 m/s) | Set based on cycle time requirements |

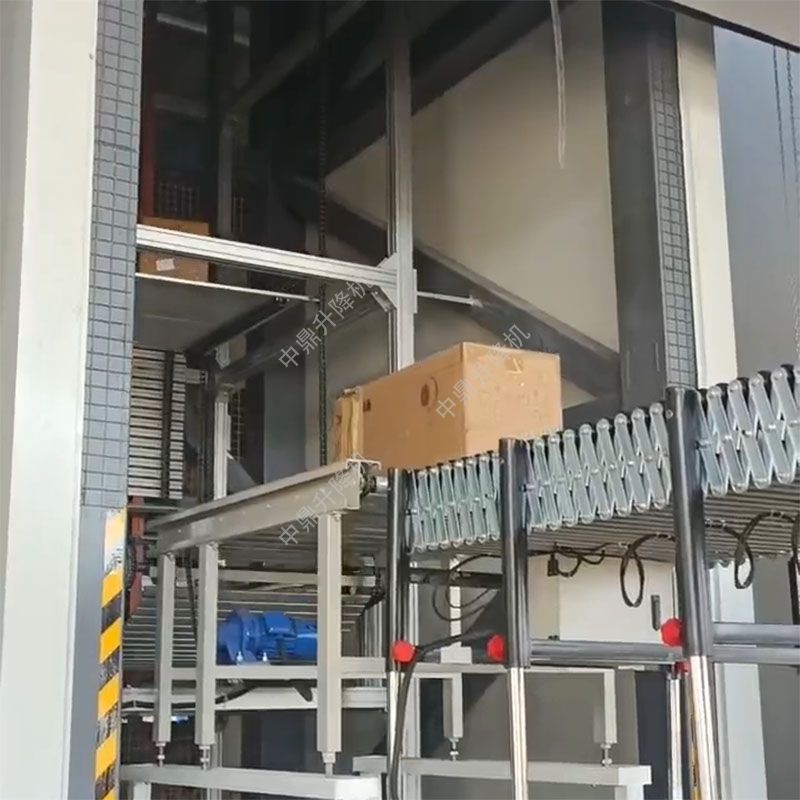

| Positioning Accuracy | ±3 mm (Typical) | Critical for smooth conveyor interface |

| Rated Load Capacity | Customizable (e.g., 150 – 300 kg) | Designed based on material weight |

| Main Frame Material | High-Quality Carbon Steel + Galvanized Treatment | Rustproof, Corrosion Resistant, Durable |

| Platform Material | Galvanized Steel Plate / Anti-Skid Plate | Sturdy, Wear-Resistant |

| Drive System | Motor Driven (Chain / Rack & Pinion / Timing Belt) | Smooth, Reliable |

| Control System | PLC Control, Variable Frequency Drive (VFD) | Integrated into production line control |

| Safety Features | Safety Light Curtains, Emergency Stop, Fall Arrest Device, Guarding | Complies with Safety Standards (e.g., CE) |

The Challenge

- Precise Integration: The lift platform must achieve exact height alignment and horizontal position (±3mm) with the roller conveyor at any stopping point within its 6-meter travel range, especially at the handover height. Any deviation risks material jamming, dropping, or conveyor damage.

- Significant Height & Stability: The 6-meter height necessitates exceptional structural rigidity and stability throughout operation, particularly at the top and bottom positions, to prevent swaying that could compromise integration accuracy and operational safety.

- Cycle Efficiency: The “reciprocating” nature requires the lift to quickly and smoothly return to the origin or next demand position after completing a transfer cycle to meet continuous production line cycle times. Optimizing the cycle path and control logic was key.

- Environmental Suitability: Industrial environments often involve dust, humidity, or mild corrosive elements, demanding robust equipment durability and protection.

- Safety Compliance: Comprehensive safety measures (light curtains, guarding, fall arrest devices) were essential in the vertical travel and horizontal transfer zones to protect personnel and equipment.

- Signal Interfacing: Reliable communication (material presence, lift request, transfer permission, status, faults) between the lift and upstream/downstream roller conveyors was crucial for coordinated, collision-free material flow.

Solutions

- Precision Guidance & Drive System: Utilized a high-rigidity mast structure (e.g., square tube or heavy-duty guide rails) with precision guidance components (linear guides or heavy-duty guide rollers) to ensure smooth, vibration-free platform travel over 6 meters. Employed high-precision servo motors or encoder-feedback VFD systems for closed-loop position control, guaranteeing the required ±3mm positioning accuracy.

- Adjustable Interface Design: Incorporated height-adjustable guide rails or transition plates on the lift platform edges to ensure smooth height and horizontal alignment with the roller conveyor. The conveyor interface featured correspondingly adjustable supports.

- Optimized Cycle Control Logic: The PLC control system intelligently planned optimal travel paths (e.g., nearest call, sequential order) based on demand signals (from different levels or upstream equipment), optimizing acceleration/deceleration profiles for fast, smooth cycling and maximizing equipment utilization.

- Galvanized Anti-Corrosion Treatment: Key metal components (main frame, platform) underwent hot-dip galvanizing or electro-galvanizing, significantly enhancing corrosion resistance, wear resistance, and lifespan for industrial environments.

- Multi-Layer Safety System: Implemented comprehensive safety light curtains (access points, platform periphery), emergency stops, mechanical fall arrest devices (safety brakes), platform overload protection, upper/lower limit switches, and necessary safety guarding. All safety signals were integrated into the PLC safety circuit.

- Standardized Communication Interface: Employed Industrial Ethernet (e.g., PROFINET, EtherNet/IP) or standard I/O signals (24VDC) for reliable communication with the PLC/MES systems of the roller conveyors, facilitating exchange of material presence, lift requests, status, and fault signals.

Advantages

- High-Efficiency Automation: Enables fully automated, continuous vertical transfer of materials across a 6-meter height difference, significantly reducing manual handling and boosting production & logistics speed.

- Optimized Space Utilization: Vertical transfer leverages building height, solving horizontal space constraints.

- Precise & Reliable Integration: High-accuracy positioning combined with adjustable interfaces ensures seamless, smooth, and dependable material handover to roller conveyors, minimizing jams and downtime.

- Exceptional Durability: Galvanization provides superior rust and corrosion protection, extending equipment life in harsh industrial settings and reducing maintenance costs.

- Reciprocating Flexibility & Efficiency: Bi-directional platform movement allows rapid response to material demands across levels, offering high cycle efficiency and adaptability.

- Smooth & Safe Operation: Precision guidance and drives ensure low-noise, stable movement. Comprehensive multi-layer safety measures provide maximum personnel and equipment protection, adhering to safety regulations.

- Easy Integration: Standardized mechanical and electrical interfaces facilitate seamless integration with existing or new roller conveyor lines and other automation equipment.

- Reduced Operational Costs: Automation replaces manual labor, lowering personnel costs. High efficiency increases throughput. Enhanced durability decreases maintenance and replacement frequency.