9.29.2025 / 5-minute read

28T Heavy-duty Omnidirectional AGV for Cable Reel Transport

Overview

In cable manufacturing, the handling of heavy reels and cable drums poses major challenges for efficiency, safety, and space utilization.

To address these issues, a 28T Heavy-duty Omnidirectional AGV has been developed, offering flexible all-direction movement, customized design for large reels, and advanced safety protection.

Equipped with a high-capacity battery and fast-charging system, it ensures efficient, safe, and automated reel transport, reduces manual dependence and accident risks, optimizes shop floor space, and supports the transition toward smart factory logistics.

Basic Parameters

| Capacity | from 1 ton to over 300 tons |

| Dimensions | on request |

| Steering systems | front axle, all axles, ± 90° steering, omnidirectional |

| Power supply | battery (electric grid or diesel generator on request) |

| Travel speed | on request (from 1 km/h to 6 km/h) |

| Drive motors | AC motors (hydraulic motors on request) |

| Steering motors | AC motors (hydraulic motors on request) |

| Command | touch panel on board, notebook/s, pulpits, customer WMS/ERP |

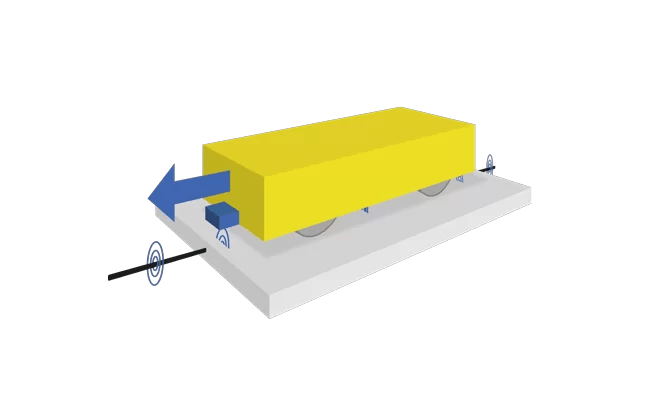

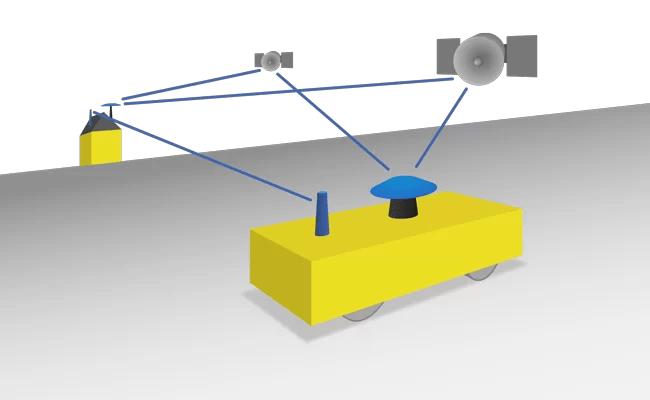

| Navigation technologies | inductive, magnetic, laser, natural, dGPS, optical, inertial |

| Kind of wheels | solid rubber, polyurethane, pneumatic |

| Lifting deck | on request (lifting stroke from 50 mm) |

| Kind of battery | lead acid, gel, lithium, pure lead |

| Battery life | on request (from 1500 m to over 15000 m) |

| Climbing ability | on request (from 1% to over 20%) |

| Operating environment | indoor, outdoor, offshore |

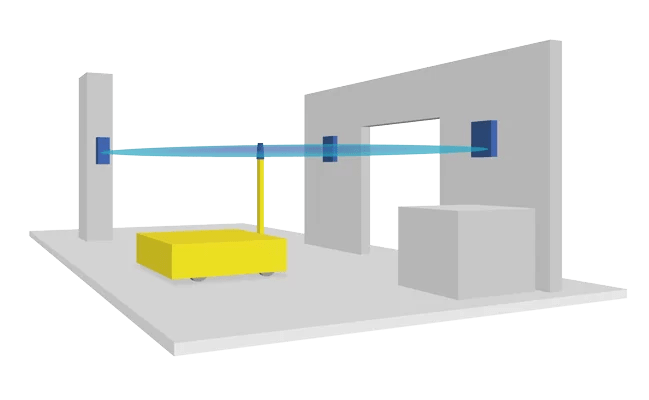

| Safety devices | laser scanners, sensitive bumpers, ultrasonic sensors |

Features

- High Load Capacity: 28-ton payload, designed for large cable reels

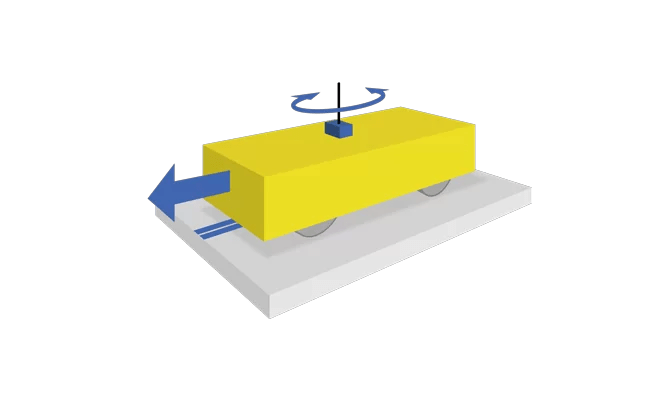

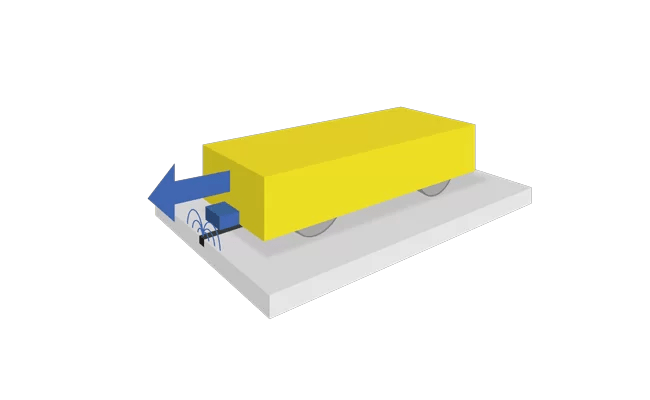

- Omnidirectional Mobility: Flexible movement and precise positioning in narrow spaces

- Safety Protection: Multi-sensor detection and intelligent obstacle avoidance

- Efficient Power: High-capacity battery with automatic fast charging for continuous operation

- Smart Integration: Reduces manual dependence, optimizes space, and supports smart factory development

Navigation Technology

Our heavy-duty AGVs are distinguished in the global market by their advanced load-handling capabilities combined with versatile navigation options. Each project is tailored in close cooperation with the customer, ensuring that the selected guidance technology—or a hybrid approach—aligns with operational demands, environmental conditions, and cost considerations. A variety of navigation systems are available to guarantee precise, safe, and efficient transport for heavy and oversized loads.

INDUCTIVE GUIDANCE

INERTIAL GUIDANCE

MAGNETIC GUIDANCE

OPTICAL GUIDANCE

LASER GUIDANCE

dGPS GUIDANCE

Solutions

- Heavy Machinery Manufacturing: Transports complete machines and components with high payload capacity. Omnidirectional movement navigates tight spaces, boosting assembly efficiency and space utilization.

- Aerospace: Handles large aircraft sections like fuselages and wings with precision. Omnidirectional capability ensures safe docking, supporting efficient pulsed assembly lines.

- Steel & Non-Ferrous Metals: Carries heavy rolls, molds, and coils. Custom tooling ensures stable transport of hot or high-value materials, optimizing process flow.

- Wind Power & New Energy: Moves massive turbine towers and blades. dGPS enables seamless indoor/outdoor navigation, providing precise positioning for oversized components.

- Automotive Manufacturing: Transfers car bodies, battery packs, and heavy dies. Omnidirectional mobility allows flexible production line integration and high-precision automated docking.

- Ports & Logistics: Shuttles containers and heavy cargo short-distance. Intelligent scheduling integrates with management systems to enhance port and warehouse automation.

- Large Molding & Injection: Automates transport of multi-ton molds. Precise scheduling reduces mold changeover time, increasing equipment utilization and production safety.