7.3.2025 / 5-minute read

Continuous Parcel Lift | 4000 pcs/hr Sorting System | Zero-Damage Vertical Conveyor | AS/RS Integration

Overview

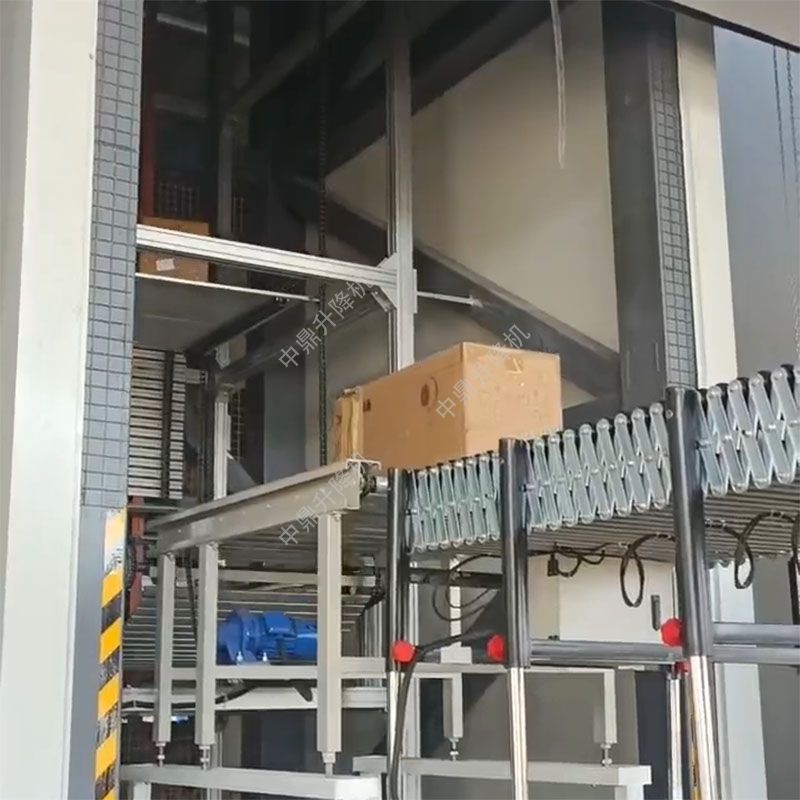

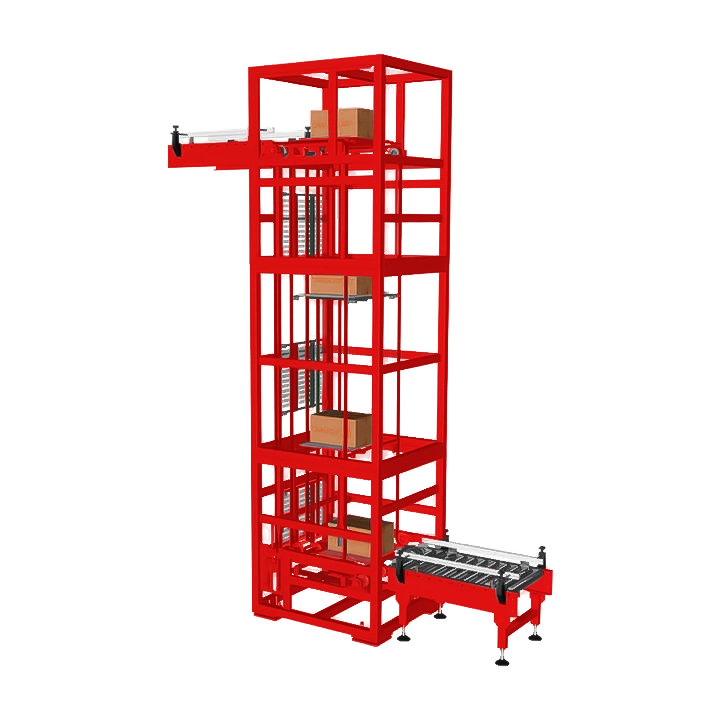

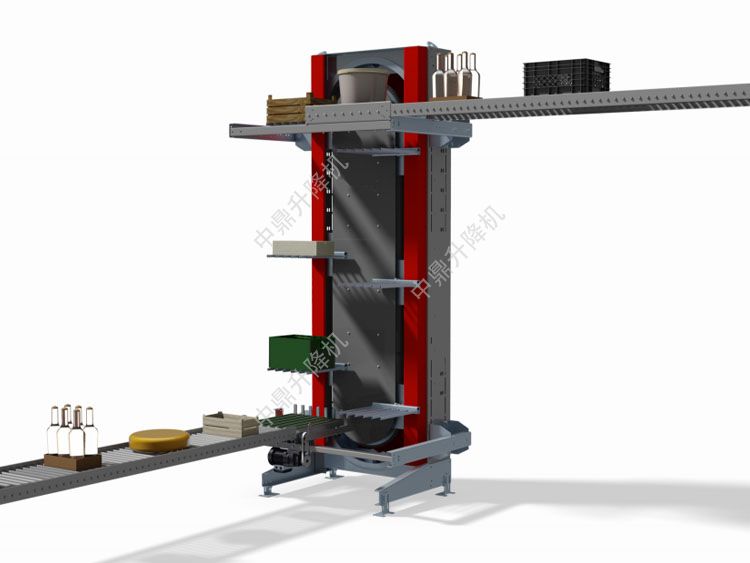

Continuous vertical conveyor engineered for express logistics hubs. Features multi-stage synchronous belt/roller drive for gap-free parcel transport:

- 24/7 Operation: VFD motors + AI scheduling (≥4000 pcs/hr peak)

- Zero-Impact Transfer: Dynamic buffer guides (spacing control ±5cm)

- Size Adaptability: Handles 500-1200mm parcels (5-30kg)

- Smart Sorting Integration: Barcode/RFID scanning with real-time routing

Basic Parameters

| Specification | Value |

|---|---|

| Capacity | 3000-4000 pcs/hr |

| Parcel Size | L:500-1200mm |

| W:300-800mm | |

| Max Load | 30kg/piece |

| Speed | 0.8-1.5m/s |

| Power | 5.5kW/level |

| Noise | ≤65dB(A) |

The Challenge

- Throughput Limit: Batch-type lifts cause idle time (peak<2000 pcs/hr)

- Parcel Damage: Free-fall transfers>0.5% breakage rate

- Mis-Sorting: Dynamic barcode scan accuracy<95%

- High Energy Waste: Conventional models>10kW power consumption

Solutions

- 2x Efficiency: 200% faster than batch lifts

- Cost Saving: <0.1% damage rate, 50% labor reduction

- Smart Ready: WCS integration with sorting robots

- Rapid Deployment: Modular assembly (72hrs setup)

Advantages

- Intrinsic Safety:

- Dual brakes + FOPS/ROPS certified cabin (10t impact resistance); 90% accident reduction.

- Operational Efficiency:

- 30% faster loading via three-sided access (cycle time ≤15 sec/unit).

- Extreme Environment Ready:

- Temperature range: -30°C to +40°C; Class 1000 cleanroom compatible.

- Durability:

- Q345A steel mast + roller bearing transmission (100,000-hour lifespan).

Application Scenarios

- Regional Hubs: Integrate with cross-belt sorter

- Airport Terminals: Connect security scanners

- E-commerce Warehouses: Sync with put-wall systems

- Last-Mile Stations: Compact multi-level sorting