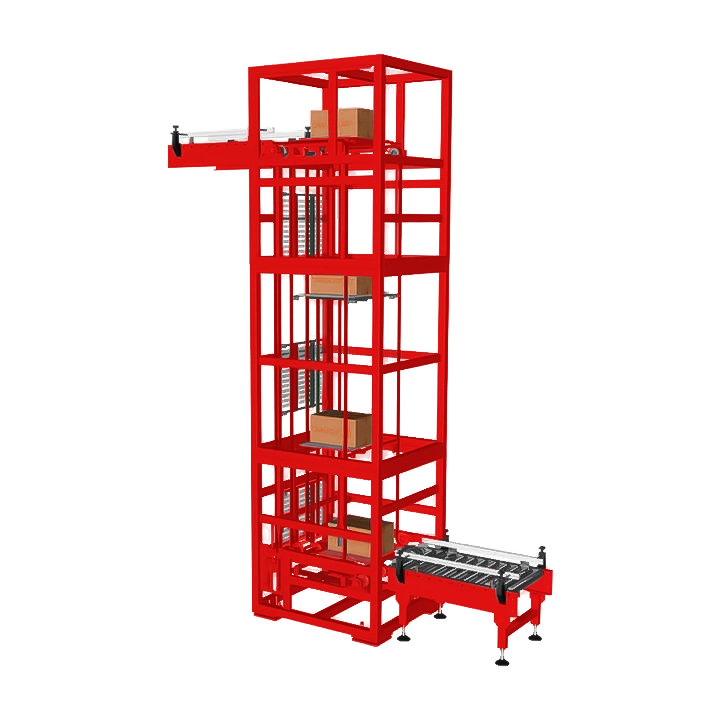

C-Type Continuous Vertical Conveyor

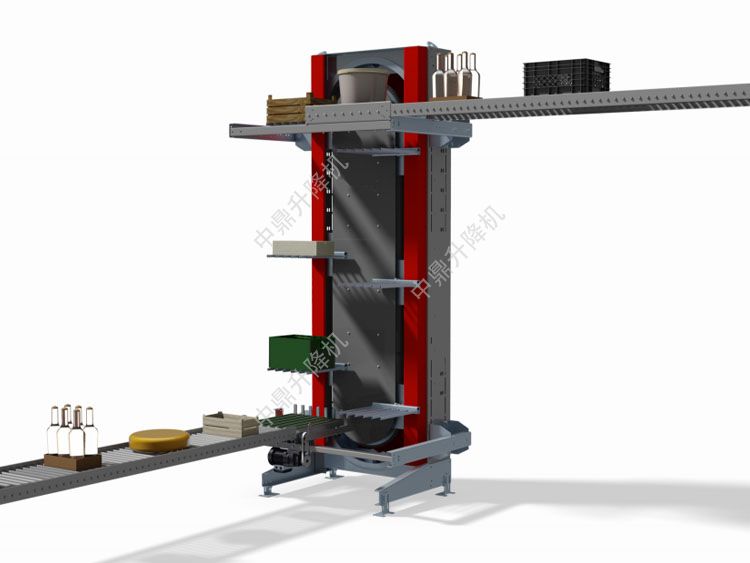

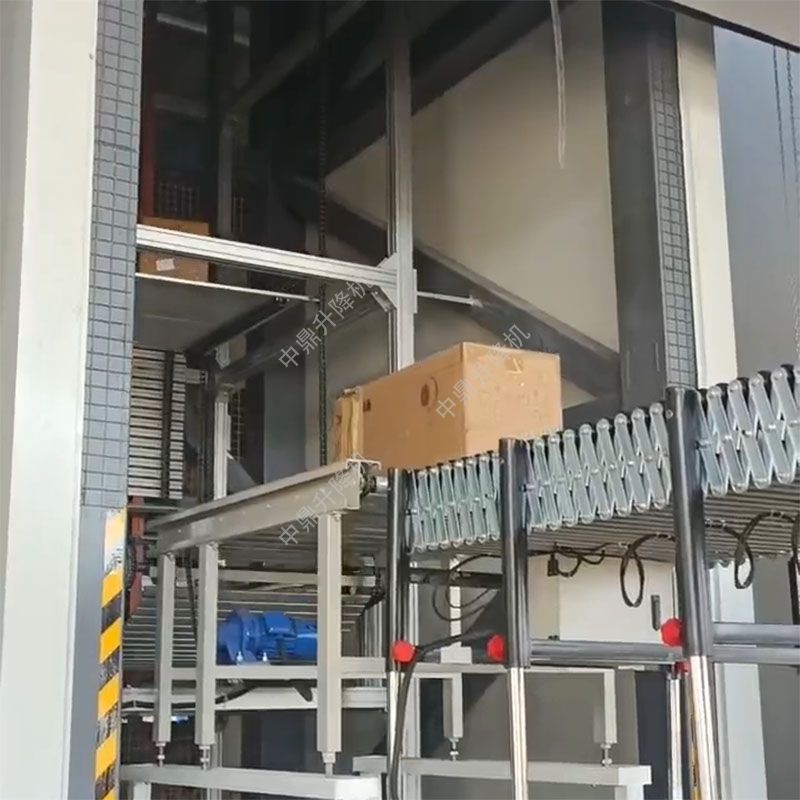

The Continuous Vertical Conveyor (CVC) is an efficient automatic material loading and conveying device, primarily used for the continuous vertical transportation of box-type components. Common configurations include “Z” type, “C” type, providing fast and stable material transport. With a compact footprint and high transfer speed, it is ideal for environments with limited space. The CVC offers high handling capacity, significantly improving the overall operational efficiency of production lines. It is widely used in manufacturing, warehousing, and logistics industries.

To find out more talk to our team

Specification

| Parameter | Specification |

|---|---|

| Equipment Type | Continuous Vertical Conveyor |

| Structural Type | C-shape / Z-shape |

| Rated Load Capacity | ≤ 500 Kg |

| Transport Capacity | ≤ 1500 pcs/h |

| Lifting Speed | ≤ 30 m/min |

| Maximum Lifting Height | 16 m |

| Conveyor Line Type | Belt Conveyor / Slat Chain Conveyor / Roller Conveyor / Chain Conveyor |

| Frame Material | Aluminum Alloy / Stainless Steel / Carbon Steel |

| Installation Method | Hoistway / Floor Opening / Bolted Fixation |

| Power Supply | 110V, 220V, 230V, 380V, 440V |

| Cargo Type | Cartons, Plastic Containers, Pallets, Barrels, Machined Parts, Loose Parts |

Features

- Efficient Conveying: The Continuous Vertical Conveyor provides fast and stable material transport, significantly improving operational efficiency and reducing waiting times in the production process.

- Space-Saving: The compact design and small footprint make it ideal for environments with limited space, especially in high-density areas.

- High Flexibility: Supports various configurations (such as Z-type, C-type), allowing customization based on different operational needs to adapt to various material handling modes.

- Automation Integration: Can be seamlessly integrated with automated production lines and logistics systems, enhancing overall logistics efficiency.

Configuration Details

| Item | Component | Specifications | Material | Quantity | Origin |

|---|---|---|---|---|---|

| Mechanical | Main Material | Aluminum Profile SD-8-8080 | Aluminum Alloy | 1 set | Shandong Steel |

| Chain Plate | SD-8-808 | Assembly | 24 pieces | Jinan Zhongding | |

| Pallet Assembly | Aluminum Alloy | 12 sets | Shandong Steel | ||

| Chain | 16A | 4 pieces | Donghua Chain | ||

| Sprocket | High-strength Alloy Steel | 8 pieces | Jinan Zhongding | ||

| Chain Guide | 30 Angle Steel | Carbon Steel | 4 pieces | Shandong Steel | |

| Power | Brake Motor | 1.5kw/380V/50HZ | 1 set | Dongli | |

| Control | PLC + Inverter | PLC + Inverter | 1 set | Siemens | |

| Contactor | As needed | As needed | Delixi | ||

| Relay | As needed | As needed | Delixi | ||

| Power Switch | 380V Power Switch | 1 piece | Taiwan Mean Well | ||

| Control Button | As needed | Delixi | |||

| Photoelectric Limit Switch | As needed | Delixi | |||

| Control Box | 1 set | Jinan Zhongding |

Explore some more

related Case studies

Proud to supply material handling equipments to all industries and for all applications

The Material Handling Equipments in your industry

The Gradin goods lifts can be used to carry pallet loads of finished products or ingredients, or equipment, up and down from a mezzanine floor or second floor. The lift’s platform can be manufactured in stainless steel so it complies with regulations, is non-corrosive and can be washed.

With musculoskeletal injuries in mind, the following is a useful, but not exhaustive, list of situations that commonly arise in the manufacturing and engineering sectors during the production process:

• Repeated manipulation of the load at a distance from the trunk of the body.

• Repeated bending of the trunk to lift the load.

• A very large load that is difficult to grasp.

• Repeated handling of the load above shoulder height or at floor level.

• Lifting that involves twisting of the trunk.

• The load needs to be carried over a long distance through a cluttered or hazardous area.

When manual handling activities involve such risks of injury (particularly to the back) due to unfavourable ergonomic conditions, the basic principle is that the employer must take measures to reduce or eliminate the risk of injury.

The Gradin goods lift is designed specifically to transport standard sized pallets from manufacturing, to and from storage on a mezzanine or first floor. If a standard specification doesn’t tick all your boxes, we also specialise in bespoke configurations, working collaboratively with you to ensure your end solution is perfect for your company, employees and products.