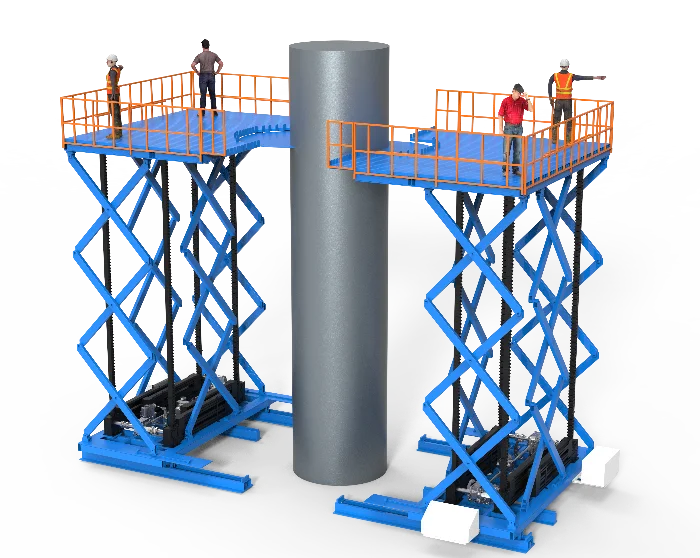

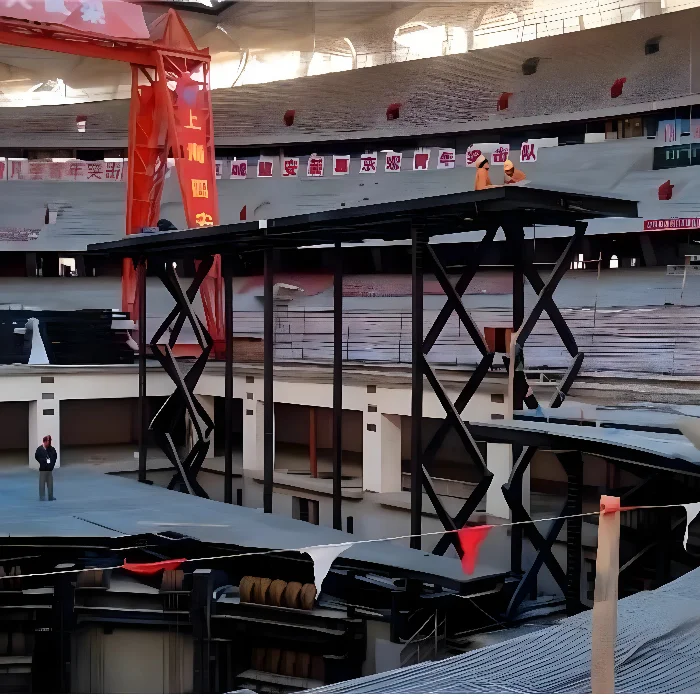

High-Accuracy Scissor Lift

This lift is suitable for high-precision lifting operations. It accurately locates the table height through hydraulic transmission and hard support, realizes the linear guide drive of the table, and provides accurate, stable and efficient lifting solutions for precision assembly, quality inspection, and heavy laboratories.

To find out more talk to our team

Specification

| Category | Parameters/Configuration | Description |

|---|---|---|

| Positioning Accuracy | ±5 mm | Utilizes a hydraulic transmission and rigid support structure, combined with a high-precision linear guide for smooth lifting. |

| Load Capacity | 500–3000 kg (customizable up to 5000 kg) | Adjusts the strength of the steel structure according to application needs, suitable for light or heavy assembly. |

| Lifting Height | 1–10 m | Single/multi-stage scissor structure, height can be customized, supports hard limit locking. |

| Platform Size | Standard: 1500×800 mm Customizable range: 800×600 mm – 5000×2500 mm | Material options: carbon steel (spray-coated for rust prevention) or stainless steel (for corrosive environments). |

| Drive Method | Hydraulic drive + servo motor control | Low noise design (≤65dB), supports stepless speed regulation. |

| Power Requirements | 220V/380V 50Hz or customizable 480V/60Hz | Optional emergency battery module (maintains basic operations for 30 minutes after power failure). |

Features

🔹 High-precision positioning: It adopts a combination of hydraulic transmission and hard support, and cooperates with high-precision linear guide guidance to achieve smooth lifting of the table. The positioning accuracy can reach ±5mm, meeting the needs of high-precision operations.

🔹 Easy operation: Equipped with a humanized control panel, the operation is simple and easy to understand, and the table lifting, stopping, locking and other functions can be easily realized.

🔹 Multiple configurations are optional: Different table sizes, load capacities, lifting heights, control methods, etc. can be customized according to customer needs to meet diverse application scenarios.

🔹 Safety sensor: The edge of the platform is equipped with a shear zone sensor to detect any obstacles or potential dangers to ensure the safety of technicians and equipment.

Enquire here

Options & Accessories

Core Options

Drive System

- Hydraulic Drive: Standard for smooth lifting, ideal for heavy loads.

- Electro-Hydraulic Hybrid Drive: Combines electric and hydraulic systems for improved efficiency.

Precision Control

- Servo Control System: Ensures high positioning accuracy (±1mm) for precision tasks.

- Multi-Speed Adjustment: Supports fast lifting and slow lowering for different operations.

Platform Material & Structure

- Anti-Slip Steel Platform: Standard design with high load capacity (5+ tons).

- Lightweight Aluminum Platform: Suitable for weight-sensitive environments (e.g., labs).

- Dual Scissor Arm Structure: Enhances stability for extra-long or heavy loads.

Installation Type

- Pit-Mounted: Saves floor space but requires pre-built pit.

- Surface-Mounted: Directly fixed to the ground for flexible deployment.

Common Accessories

Safety Features

- Fall Arrest Device: Locks the platform in case of hydraulic failure.

- Overload Protection Sensor: Stops operation and alerts when exceeding weight limits.

- Emergency Stop Button: Instantly cuts power for safety.

Control & Display

- Wireless Remote Control: Enables remote operation.

- Touchscreen Panel: Displays real-time height and diagnostics.

Functional Add-Ons

- Guide Rail System: Improves stability for high lifts (10m+).

- Extendable Platform: Expands workspace for large cargo.

- Dust/Waterproof Covers: Protects hydraulic and electrical components.

Proud to supply material handling equipments to all industries and for all applications

The Material Handling Equipments in your industry

The Gradin goods lifts can be used to carry pallet loads of finished products or ingredients, or equipment, up and down from a mezzanine floor or second floor. The lift’s platform can be manufactured in stainless steel so it complies with regulations, is non-corrosive and can be washed.

With musculoskeletal injuries in mind, the following is a useful, but not exhaustive, list of situations that commonly arise in the manufacturing and engineering sectors during the production process:

• Repeated manipulation of the load at a distance from the trunk of the body.

• Repeated bending of the trunk to lift the load.

• A very large load that is difficult to grasp.

• Repeated handling of the load above shoulder height or at floor level.

• Lifting that involves twisting of the trunk.

• The load needs to be carried over a long distance through a cluttered or hazardous area.

When manual handling activities involve such risks of injury (particularly to the back) due to unfavourable ergonomic conditions, the basic principle is that the employer must take measures to reduce or eliminate the risk of injury.

The Gradin goods lift is designed specifically to transport standard sized pallets from manufacturing, to and from storage on a mezzanine or first floor. If a standard specification doesn’t tick all your boxes, we also specialise in bespoke configurations, working collaboratively with you to ensure your end solution is perfect for your company, employees and products.