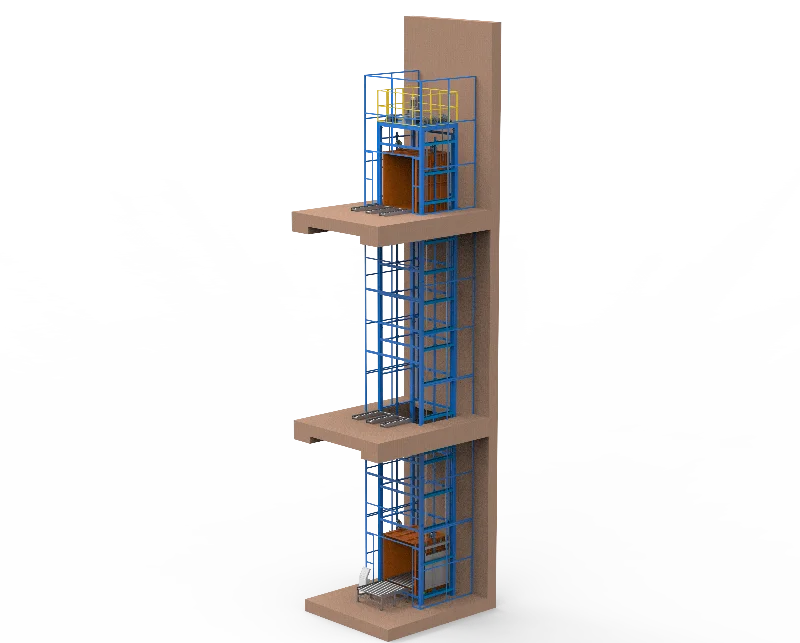

Four-Post E-type VRC Lift

The 4-post E-type vertical reciprocating conveyor is especially suitable for multi-story material transport, particularly in applications requiring same-side loading and unloading. Its same-side loading and unloading design simplifies the process, effectively improving operational efficiency. It is ideal for environments that require vertical transport across multiple floors, such as multi-story warehouses, distribution centers, and production workshops. By providing stable vertical conveyance, the 4-post E-type VRC allows for the fast and safe movement of materials between floors, saving space and maximizing workflow efficiency.

To find out more talk to our team

Specification

Maximum Load Capacity

- Range: 5–30 tons (customizable higher)

- Feature: Four-post structure with reinforced beams for extreme heavy loads (e.g., industrial machinery, shipping containers).

Loading/Unloading Mode

- Type: E-Type (End/Bilateral Loading)

- Feature: Open-end platform design enables loading from both sides or ends, ideal for production line integration.

Lifting Height

- Range: ≤30 meters (ultra-high vertical transport)

- Feature: Dual hydraulic synchronization or gear-rack drive ensures stability in deep-shaft applications (e.g., mines, high-rise construction).

Safety & Drive System

- Dual fall arrest systems (mechanical + hydraulic)

- 3D laser obstacle detection

- Hydraulic (heavy loads)

- Electric gear-rack (high-speed, 0.2–1.0 m/s).

Features

🔹 Multi-floor Applicability: Suitable for material transport between multiple floors, efficiently and stably moving goods between levels, saving space and improving logistics efficiency.

🔹 High Flexibility: Supports multiple loading and unloading modes, allowing for the selection of the appropriate entry and exit method based on operational needs to meet different logistics processes.

🔹 High Operational Efficiency: Ideal for complex material handling tasks, improving the efficiency of transitions between different logistics processes.

🔹 Safety Assurance: Equipped with multiple safety features, such as limit switches, anti-fall systems, and emergency stop buttons, ensuring the safety of operators and equipment.

Enquire here

Options & Accessories

Safety & Control Systems

- Dual Redundant Fall Arrest Locks: Mechanical + hydraulic dual locking system that automatically locks the guide rail in case of power failure or malfunction.

- 3D Laser Obstacle Detection: Real-time scanning of protruding cargo to prevent collisions with structures.

- Multilingual Touchscreen: Supports interfaces in Chinese, English, Arabic, etc., suitable for global operations.

Loading Aids & Platform Extensions

- Bilateral Extendable Bridge Plates: Single-side extension of 0.5–2 meters, designed for loading and unloading oversized cargo.

- Modular Roller Tracks: Each roller supports a load of 2 tons, allowing bidirectional access for AGVs/forklifts.

- Removable Impact Guards: Hydraulic folding design for quick switching between open and closed modes.

Environmental Adaptation Kits

- High-Temp Hydraulic Kit: Suitable for environments up to 80°C (such as steel mills and foundries).

- Explosion-Proof Certification: Compliant with ATEX/Ex standards, suitable for oil, gas, and chemical hazardous areas.

- Deep-Sea Anti-Corrosion Coating: C6-M level protection against seawater corrosion (for offshore platforms).

Drive & Energy Efficiency

- Dual Hydraulic Synchronous Drive: Smooth lifting and lowering for loads over 30 tons, with synchronization accuracy of ±1mm.

- Regenerative Energy Recovery: Recovers electricity to the grid during descent, saving 15–20% energy.

The Four-Post E-type VRC Lift revolutionized our mining operations in the Amazon – its 16-ton capacity handles ore transport effortlessly, while the dual-side loading cut logistics time by 40%. The C6-M coating withstands 90% humidity without corrosion, and the Portuguese control interface improved operator safety. Local service technicians reduced downtime by 50%. The ultimate heavy-duty solution for tropical industrial challenges!

The Material Handling Equipments in your industry

The Gradin goods lifts can be used to carry pallet loads of finished products or ingredients, or equipment, up and down from a mezzanine floor or second floor. The lift’s platform can be manufactured in stainless steel so it complies with regulations, is non-corrosive and can be washed.

With musculoskeletal injuries in mind, the following is a useful, but not exhaustive, list of situations that commonly arise in the manufacturing and engineering sectors during the production process:

• Repeated manipulation of the load at a distance from the trunk of the body.

• Repeated bending of the trunk to lift the load.

• A very large load that is difficult to grasp.

• Repeated handling of the load above shoulder height or at floor level.

• Lifting that involves twisting of the trunk.

• The load needs to be carried over a long distance through a cluttered or hazardous area.

When manual handling activities involve such risks of injury (particularly to the back) due to unfavourable ergonomic conditions, the basic principle is that the employer must take measures to reduce or eliminate the risk of injury.

The Gradin goods lift is designed specifically to transport standard sized pallets from manufacturing, to and from storage on a mezzanine or first floor. If a standard specification doesn’t tick all your boxes, we also specialise in bespoke configurations, working collaboratively with you to ensure your end solution is perfect for your company, employees and products.