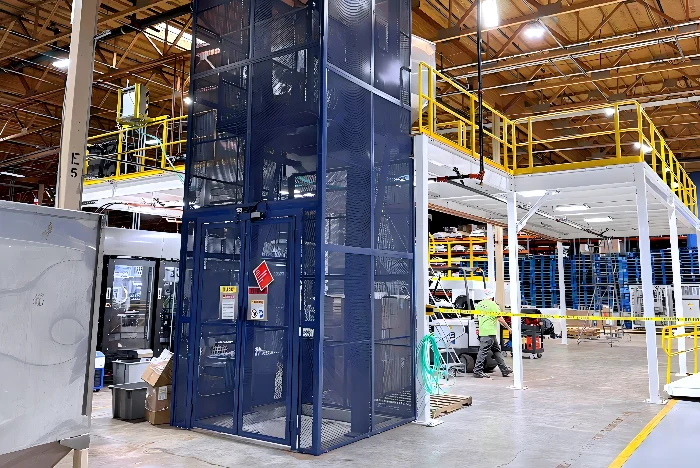

Four-Post C-type VRC Lift

The 4-post C-type vertical reciprocating conveyor (VRC) is an efficient and flexible vertical transport device, specifically designed for applications where loading and unloading are done from the same side. The system allows goods to be loaded and unloaded from the same side, offering a convenient operation mode that greatly enhances operational efficiency. The 4-post structure ensures higher load capacity and stability, making it suitable for handling materials of various sizes and weights, particularly large or heavy loads. Its compact design allows for efficient operation in space-constrained environments, optimizing logistics processes while improving safety and ease of operation.

To find out more talk to our team

Specification

Maximum Load Capacity

- Range: 3–20 tons (customizable for higher capacities)

- Features: The four-column structure disperses the load, providing stability far superior to double-column/single-column designs, suitable for transporting heavy equipment (such as machine tools and industrial molds).

Lift Height

- Range: 3–30 meters (vertical travel)

- Features: A counterweight balancing system is required for high travel to ensure smooth lifting, suitable for multi-story factories or storage centers.

Platform Dimensions

- Typical values: Width 2–5 meters × Depth 1.5–4 meters (expandable)

- Features: The C-frame design reinforces edge support, accommodating oversized/extra-wide goods (such as steel structure beams and large machinery).

Lifting Speed

- Range: 0.1–0.5 meters/second (variable frequency speed control)

- Features: The low-speed setting is used for precise positioning (±2mm accuracy), while the high-speed setting enhances efficiency (such as in automotive production lines).

Features

🔹 C-type Loading and Unloading: Supports C-type loading and unloading (loading and unloading from the same side), providing a convenient operating mode that improves operational efficiency.

🔹 Strong Adaptability: C-type loading and unloading is ideal for applications requiring frequent loading and unloading, especially for material transport that needs to be processed quickly, optimizing the production process.

🔹 Space-saving: The C-type configuration provides an effective transport solution in limited spaces, making it suitable for environments with space constraints.

🔹 Safety Assurance: Equipped with multiple safety features, such as limit switches, anti-fall systems, and emergency stop buttons, ensuring the safety of both operators and equipment.

Enquire here

Options & Accessories

Safety & Control Systems

- Fall Arrest Locks: Mechanical locking mechanism engages during power failure.

- Light Curtains/Safety Edges: Obstacle detection with emergency stop (ANSI/ASME compliant).

- Overload Protection: Auto-shutoff when load exceeds 110% capacity.

- PLC with touchscreen (multi-floor presets, diagnostics).

- Wireless remote (AGV/automation compatible).

Loading Aids & Platform Configurations

- Extendable Bridge Plates: 0.5–1.5m ramps for gap bridging.

- Modular Guardrails: Foldable/removable for oversized loads.

- Anti-Slip Surfaces: Diamond-pattern steel (coefficient ≥0.6).

- Heavy-Duty Roller Tracks: 1-ton/wheel capacity (for high-impact areas).

Safety Mechanisms

- Galvanized/Epoxy coating (C5-M standard).

- Stainless steel platforms (304/316L, FDA-compliant).

- Anti-condensation heaters (-40°C operation).

- Explosion-proof motors (ATEX/Ex certified).

Drive & Energy Efficiency

- Hydraulic (3–20 tons, smooth operation).

- Electric chain (high-speed, 0.1–0.5 m/s).

- Regenerative braking (10–15% power savings).

Our Four-Post C-type VRC Lift handles 15-ton oilfield equipment flawlessly in the desert heat. The galvanized coating resists sand corrosion, and hydraulic drive ensures smooth lifts up to 10m. The C-type loading saves space in our tight yard, while the Arabic-language PLC touchscreen simplifies operation. Perfect for heavy industry in harsh climates – a reliable, low-maintenance solution backed by local Saudi technical support.

The Material Handling Equipments in your industry

The Gradin goods lifts can be used to carry pallet loads of finished products or ingredients, or equipment, up and down from a mezzanine floor or second floor. The lift’s platform can be manufactured in stainless steel so it complies with regulations, is non-corrosive and can be washed.

With musculoskeletal injuries in mind, the following is a useful, but not exhaustive, list of situations that commonly arise in the manufacturing and engineering sectors during the production process:

• Repeated manipulation of the load at a distance from the trunk of the body.

• Repeated bending of the trunk to lift the load.

• A very large load that is difficult to grasp.

• Repeated handling of the load above shoulder height or at floor level.

• Lifting that involves twisting of the trunk.

• The load needs to be carried over a long distance through a cluttered or hazardous area.

When manual handling activities involve such risks of injury (particularly to the back) due to unfavourable ergonomic conditions, the basic principle is that the employer must take measures to reduce or eliminate the risk of injury.

The Gradin goods lift is designed specifically to transport standard sized pallets from manufacturing, to and from storage on a mezzanine or first floor. If a standard specification doesn’t tick all your boxes, we also specialise in bespoke configurations, working collaboratively with you to ensure your end solution is perfect for your company, employees and products.