29.4.2025 / 3 minute read

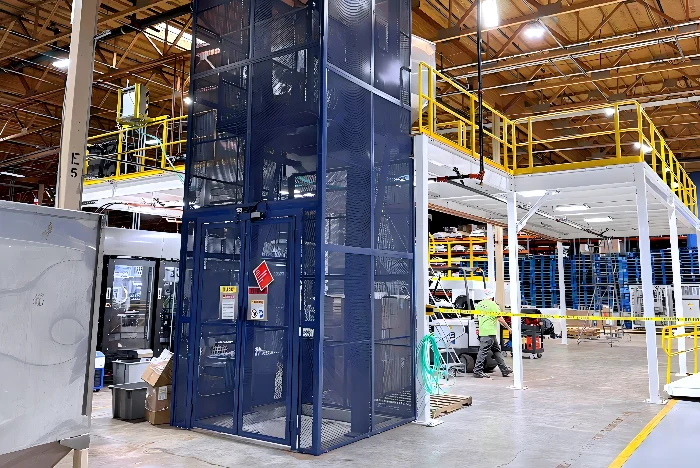

4-Post C-Type Vrc Lift: Vertical Logistics Expert for Smart Manufacturing Factories

Key points –

- Efficient space utilization: The compact C-shaped track design can be installed along the plant column, saving valuable production space.

- Precise material positioning: Using a servo control system, the positioning accuracy can reach ±1mm.

- Super load capacity: The heavy-duty design can carry more than 2 tons of materials for smooth lifting.

- Intelligent interconnection: Supports docking with the MES system to achieve digital management of production logistics.

Application Scenario Analysis

- Auto parts factory: Accurate material transfer between different processes.

- Electronics manufacturing workshop: Safe transportation of precision components.

- Food processing plants: Vertical transport of raw materials in compliance with hygienic standards.

- Pharmaceutical production line: clean environment material flow that meets GMP requirements.

The Challenge

In the complex environment of a manufacturing plant, 4-Post C-Type VRC Lifts face multiple application challenges. The material specifications of different production links vary greatly, and different requirements are placed on the carrier design from precision parts to heavy raw materials. Harsh industrial environments such as dust, oil pollution, temperature and humidity changes affect the long-term stability of the equipment. In addition, the rhythm matching and space coordination with the existing production line also require overcoming many technical difficulties.

Solutions

In response to the special requirements of manufacturing scenarios, the new generation of equipment adopts a modular carrier system, which can quickly replace handling platforms with different functions. Key components adopt industrial-grade protection design, equipped with self-cleaning guide rails and sealed bearings to ensure reliable operation in harsh environments. The intelligent beat adjustment system can automatically identify the status of the previous and next processes to achieve seamless connection. The compact track design can flexibly adapt to various plant structures to minimize the impact on existing production lines.

Advantages

The 4-Post C-Type VRC Lift brings significant logistics innovation to manufacturing plants. Its space-fitting design maximizes the use of valuable production areas. Precise servo control ensures accurate flow of materials between complex processes, greatly reducing production errors. The intelligent interconnection function can achieve deep integration with the MES system, which not only improves the efficiency of a single link, but also optimizes the overall production logistics system. It is an indispensable key equipment for intelligent manufacturing.

Explore some more

related Case studies

Proud to supply material handling equipments to all industries and for all applications

The Material Handling Equipments in your industry

The Gradin goods lifts can be used to carry pallet loads of finished products or ingredients, or equipment, up and down from a mezzanine floor or second floor. The lift’s platform can be manufactured in stainless steel so it complies with regulations, is non-corrosive and can be washed.

With musculoskeletal injuries in mind, the following is a useful, but not exhaustive, list of situations that commonly arise in the manufacturing and engineering sectors during the production process:

• Repeated manipulation of the load at a distance from the trunk of the body.

• Repeated bending of the trunk to lift the load.

• A very large load that is difficult to grasp.

• Repeated handling of the load above shoulder height or at floor level.

• Lifting that involves twisting of the trunk.

• The load needs to be carried over a long distance through a cluttered or hazardous area.

When manual handling activities involve such risks of injury (particularly to the back) due to unfavourable ergonomic conditions, the basic principle is that the employer must take measures to reduce or eliminate the risk of injury.

The Gradin goods lift is designed specifically to transport standard sized pallets from manufacturing, to and from storage on a mezzanine or first floor. If a standard specification doesn’t tick all your boxes, we also specialise in bespoke configurations, working collaboratively with you to ensure your end solution is perfect for your company, employees and products.