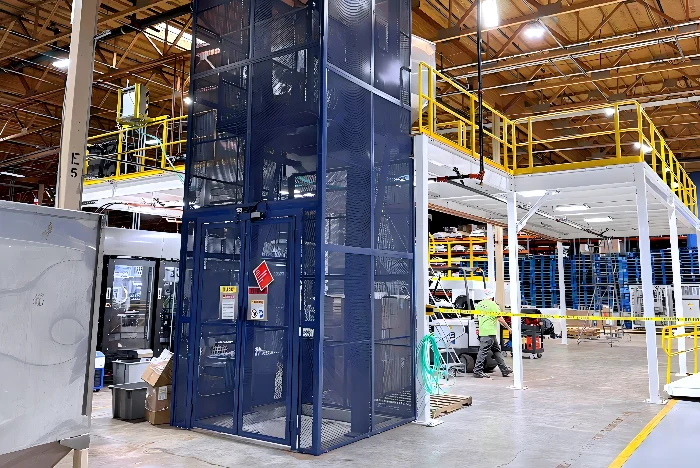

4-Post C-Type Vrc Lift: Intelligent Solution for Efficient Logistics of Modern Production Lines

Key points –

- High space utilization.

- Stable and reliable operation.

- Strong load capacity.

- Intelligent control.

Application Scenario Analysis

Automobile manufacturing: Precise transportation of car body parts between different workstations.

Food and Beverage: Realize hygienic vertical transportation of raw materials and finished products.

Electronics manufacturing: Safe transportation of precision components on production lines on different floors.

Pharmaceutical and chemical industry: Automated material transfer in compliance with GMP requirements.

The Challenge

In the production line environment, 4-Post C-Type VRC Lifts face multiple challenges. The difference in the beat of different production links easily causes material accumulation, and the size specifications of diversified products put forward higher requirements on the adaptability of the loading platform. At the same time, the stability maintenance of the equipment under continuous high-intensity operation has also become a test, especially in the production workshop with large changes in temperature and humidity.

Solutions

To address these challenges, intelligent beat adjustment technology can be used to automatically adjust the operating speed according to the requirements of the previous and next processes. The modular loading platform design enables rapid changeover to meet the production needs of multiple varieties. In addition, key components are made of special alloy materials and equipped with an automatic lubrication system, which can significantly improve the durability of the equipment in harsh environments.

Advantages

The 4-Post C-Type VRC Lift has brought revolutionary efficiency improvements to the production line. Its compact structure can be perfectly integrated into the existing production line layout without affecting the operation of other equipment. Compared with traditional conveying methods, its precise positioning function ensures the accuracy of material handover and greatly reduces the production error rate. More importantly, this elevator effectively controls labor costs and improves operational safety by reducing manual handling links.

Explore some more

related Case studies

Proud to supply material handling equipments to all industries and for all applications

The Material Handling Equipments in your industry

The Gradin goods lifts can be used to carry pallet loads of finished products or ingredients, or equipment, up and down from a mezzanine floor or second floor. The lift’s platform can be manufactured in stainless steel so it complies with regulations, is non-corrosive and can be washed.

With musculoskeletal injuries in mind, the following is a useful, but not exhaustive, list of situations that commonly arise in the manufacturing and engineering sectors during the production process:

• Repeated manipulation of the load at a distance from the trunk of the body.

• Repeated bending of the trunk to lift the load.

• A very large load that is difficult to grasp.

• Repeated handling of the load above shoulder height or at floor level.

• Lifting that involves twisting of the trunk.

• The load needs to be carried over a long distance through a cluttered or hazardous area.

When manual handling activities involve such risks of injury (particularly to the back) due to unfavourable ergonomic conditions, the basic principle is that the employer must take measures to reduce or eliminate the risk of injury.

The Gradin goods lift is designed specifically to transport standard sized pallets from manufacturing, to and from storage on a mezzanine or first floor. If a standard specification doesn’t tick all your boxes, we also specialise in bespoke configurations, working collaboratively with you to ensure your end solution is perfect for your company, employees and products.