Stainless Steel Scissor Lift Platform

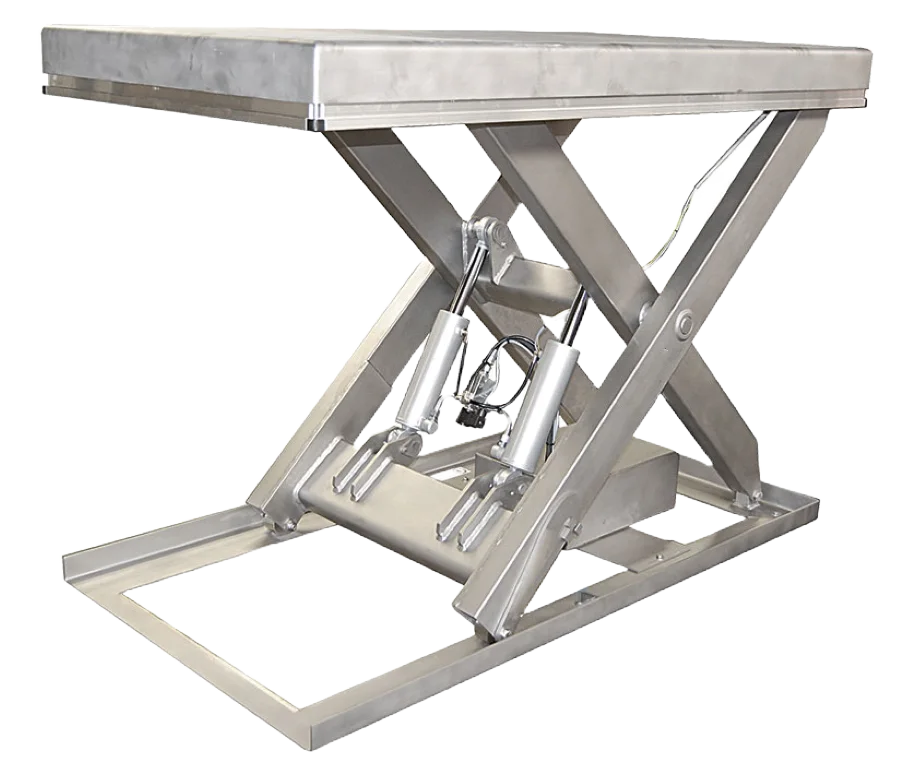

Product introduction: In industries such as food and medicine that have extremely high requirements for hygiene and safety, the cleanliness of the production environment is directly related to product quality. To this end, we launched the 316 food-grade stainless steel scissor lift platform, which is specially designed for clean workshops to help companies create a safe and efficient production environment.

To find out more talk to our team

Specification

| Parameter | Description |

|---|---|

| Rated Load | 300kg – 6000kg (graded by model) |

| Lifting Height | 0.2 – 18m (most standard models concentrated in the 2-6m range) |

| Platform Size | Standard: 1850×960mm (small platform) |

| Customized: 7000×2500mm (large platform) | |

| Self Height | 900-1560mm (inversely related to lifting stroke) |

| Motor Power | 3kW (basic model) – 11kW (heavy-duty model) |

| Power Specifications | 380V/50Hz (industrial standard configuration) |

| Lifting Speed | 4-8cm/s (the greater the load, the slower the speed) |

| Main Material | 304 stainless steel (full steel structure with anti-rust treatment) |

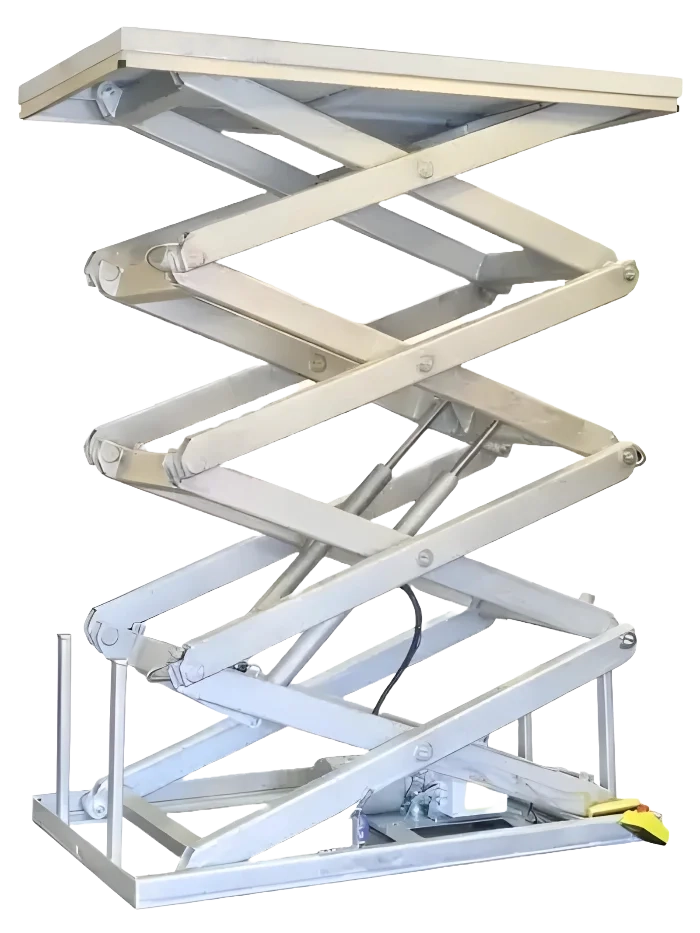

| Scissor Levels | Single scissor (light duty) – double scissor (heavy duty) |

| Safety Devices | Standard mechanical locking + emergency descent valve |

Features

🔹 Safety and hygiene: The tabletop is made of 316 food-grade stainless steel, which has excellent corrosion resistance, high temperature resistance and easy cleaning, effectively preventing bacteria from growing and ensuring product hygiene and safety.

🔹 Sturdy and durable: It adopts advanced bending technology, has a stable structure, strong load-bearing capacity, and long service life, meeting the needs of high-intensity operations.

🔹 Easy to clean: The surface is smooth and flat, with no sanitary dead corners, and can be quickly cleaned and disinfected, meeting the hygiene standards of clean workshops.

🔹 Smooth lifting: It adopts a scissor-type lifting mechanism, which runs smoothly and has precise positioning to meet the needs of operations at different heights.

Enquire here

Options & Accessories

Safety Protection

- Anti-Slip Surface: Slip-resistant panel with diamond pattern or rubber coating

- Safety Guardrails: Removable stainless steel railing (height typically 1-1.2m)

- Emergency Stop Button: Red emergency stop switch compliant with CE standards

Functional Extensions

- Hydraulic Leveling System: Automatic leveling correction for inclined surfaces

- Extendable Platform: Expands work area to 150% of original size

- Caster Kit: Swivel casters with brake function (suitable for indoor mobility)

Power Configuration

- Explosion-Proof Motor: Suitable for hazardous environments such as chemical and energy sectors

- Battery Backup System: Maintains platform stability for over 30 minutes after power loss

Special Customization

- Cleanroom Version: Dust-free design compliant with GMP standards

- Low-Temperature Environment Kit: Hydraulic oil and seals designed for -20℃ operating conditions

- Weighing Module Integration: Built-in digital display (accuracy ±0.5%)

Proud to supply material handling equipments to all industries and for all applications

The Material Handling Equipments in your industry

The Gradin goods lifts can be used to carry pallet loads of finished products or ingredients, or equipment, up and down from a mezzanine floor or second floor. The lift’s platform can be manufactured in stainless steel so it complies with regulations, is non-corrosive and can be washed.

With musculoskeletal injuries in mind, the following is a useful, but not exhaustive, list of situations that commonly arise in the manufacturing and engineering sectors during the production process:

• Repeated manipulation of the load at a distance from the trunk of the body.

• Repeated bending of the trunk to lift the load.

• A very large load that is difficult to grasp.

• Repeated handling of the load above shoulder height or at floor level.

• Lifting that involves twisting of the trunk.

• The load needs to be carried over a long distance through a cluttered or hazardous area.

When manual handling activities involve such risks of injury (particularly to the back) due to unfavourable ergonomic conditions, the basic principle is that the employer must take measures to reduce or eliminate the risk of injury.

The Gradin goods lift is designed specifically to transport standard sized pallets from manufacturing, to and from storage on a mezzanine or first floor. If a standard specification doesn’t tick all your boxes, we also specialise in bespoke configurations, working collaboratively with you to ensure your end solution is perfect for your company, employees and products.