Explosion-Proof Scissor Lift Platform

Our Explosion-proof scissor lift platform is a specialized lifting equipment designed to prevent explosions caused by sparks, electric arcs, or high-temperature gases. It uses explosion-proof motors, explosion-proof control systems, and sealed protection designs, effectively isolating flammable gases or dust in the external environment, ensuring safe operation in hazardous conditions. It is commonly used in chemical plants, oil and gas industries, coal mines, power plants, warehouses, and other hazardous areas, ensuring the safe vertical transportation of goods in harsh environments.

To find out more talk to our team

Specification

| Parameter | Specification |

|---|---|

| Model Number | EP-SLP-XX (Customizable for load capacity and height) |

| Load Capacity | 1,000–5,000 kg (adjustable for industrial requirements) |

| Lifting Height | 3–15 m (hydraulic-driven scissor mechanism) |

| Platform Size | 2,000×1,200 mm (standard) / Customizable up to 5,000×2,500 mm |

| Power Source | Explosion-proof motor (380V/50Hz) |

| Control System | Explosion-proof PLC with emergency stop, overload protection, and anti-tilt |

| Operating Temp. | -20°C to +50°C (with frost/heat-resistant hydraulic oil) |

Features

🔹 Explosion-Proof Design: Equipped with explosion-proof motors, explosion-proof control systems, and sealed protection designs to ensure safe operation in hazardous environments.

🔹 High Safety: Effectively isolates flammable gases or dust to prevent sparks or electric arcs from causing explosions.

🔹 Waterproof and Dustproof: Equipped with a sealing system to prevent external moisture and dust from entering the equipment, making it suitable for harsher working conditions.

🔹 Low Maintenance Cost: Simple structure for easy maintenance, reducing failure rates and lowering long-term operating costs.

Enquire here

Options & Accessories

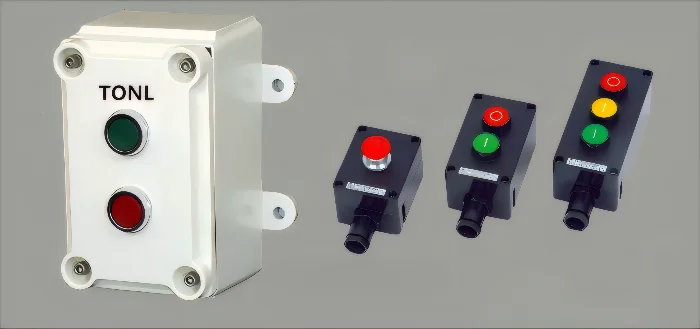

Explosion-Proof Components

Motors & Controls:

Certified explosion-proof hydraulic power units.

Ex d/e rated control panels with emergency stop (IP65/IP66).

Electrical Systems:

Explosion-proof wiring, junction boxes, and limit switches.

Intrinsically safe (IS) remote controls or pendant stations.

Material Upgrades:

Stainless steel or anti-corrosive coatings for harsh environments.

Spark-resistant platform flooring (e.g., aluminum or non-sparking composite).

Safety & Operational Accessories

Safety Features:

Emergency descent system (manual or battery backup).

Safety rails, toe guards, and anti-slip surfaces.

Overload protection sensors and interlocking gates.

Fall arrest anchorage points (OSHA/EN compliant).

Operational Enhancements:

Platform extensions or foldable sections for expanded workspace.

Rotating turntable (360° rotation option).

Adjustable tilt or leveling jacks for uneven surfaces.

Installation & Maintenance

Mounting Kits:

Anchor bolts, base frames, or pit-mounting systems.

Maintenance Tools:

Lubrication kits, hydraulic fluid reservoirs, and service manuals.

Explosion-proof lighting for maintenance in dark areas.

Monitoring Systems:

Condition monitoring sensors (vibration, temperature).

Wireless diagnostics for predictive maintenance.

Export-Specific Requirements

Documentation:

Multilingual manuals (English, Spanish, French, etc.).

CE/UKCA marking, test certificates, and EX-proof dossier.

Packaging:

Weatherproof crating with anti-rust VCI packaging.

Compliance with ISPM 15 for wooden materials.

Customization:

Voltage/frequency adjustments for target countries.

Localized labels and hazard warnings (e.g., OSHA, ISO symbols).

Optional Add-Ons

Environmental Adaptations:

HVAC systems for extreme temperatures (-20°C to +50°C).

Dust-tight or waterproof enclosures (IP67).

Advanced Controls:

PLC automation with HMI touchscreen.

RFID or biometric access control.

Lighting:

Explosion-proof LED worklights (integrated into the platform).

Proud to supply material handling equipments to all industries and for all applications

The Material Handling Equipments in your industry

The Gradin goods lifts can be used to carry pallet loads of finished products or ingredients, or equipment, up and down from a mezzanine floor or second floor. The lift’s platform can be manufactured in stainless steel so it complies with regulations, is non-corrosive and can be washed.

With musculoskeletal injuries in mind, the following is a useful, but not exhaustive, list of situations that commonly arise in the manufacturing and engineering sectors during the production process:

• Repeated manipulation of the load at a distance from the trunk of the body.

• Repeated bending of the trunk to lift the load.

• A very large load that is difficult to grasp.

• Repeated handling of the load above shoulder height or at floor level.

• Lifting that involves twisting of the trunk.

• The load needs to be carried over a long distance through a cluttered or hazardous area.

When manual handling activities involve such risks of injury (particularly to the back) due to unfavourable ergonomic conditions, the basic principle is that the employer must take measures to reduce or eliminate the risk of injury.

The Gradin goods lift is designed specifically to transport standard sized pallets from manufacturing, to and from storage on a mezzanine or first floor. If a standard specification doesn’t tick all your boxes, we also specialise in bespoke configurations, working collaboratively with you to ensure your end solution is perfect for your company, employees and products.