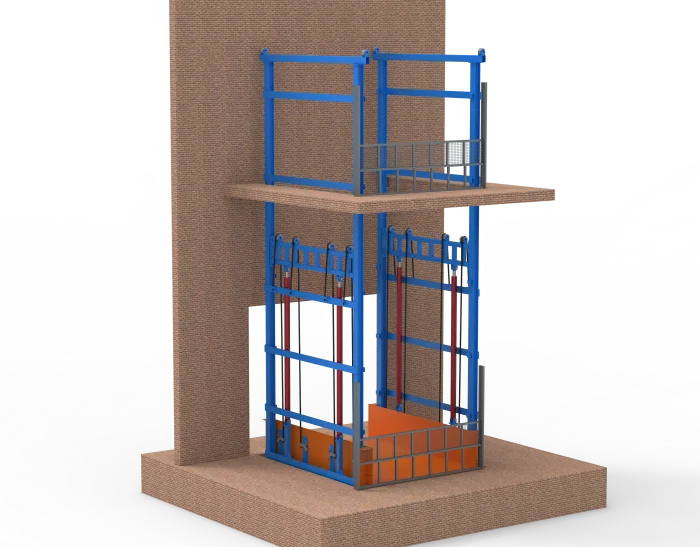

4-Post 4-Cylinder Goods Lift

Optimized for elongated cargo (steel beams, pipes, timber), dual-end hydraulic cylinders synchronize lifting force across a 4-guide-rail framework, ensuring lateral stability and tilt-free operation. Compact design adapts to narrow spaces while supporting loads up to 10 tons. Built with high-strength steel and anti-wear coatings for industrial durability.

To find out more talk to our team

Specification

Capacity: ≤ 10000kg

Length/Deepth: 4-6m

Lifting Height: from 2,500mm

4-8 weeks from order to install

Price: from $4000

Enquire hereFeatures

🔹 Applied to scenarios involving the lifting of longer goods.

🔹 Structure: 4 oil cylinders (4 cylinders) and 4 guide rails (4 columns).

🔹 The oil cylinders are placed near both ends of the platform to ensure the stability of the equipment.

🔹 Smart synchronization control: Automatically balances cylinder pressure to prevent tilting.

🔹 Modular maintenance design: Quick-access components reduce downtime in high-intensity operations.

Enquire here

Options & Accessories

🔹Safety Enhancements

Dual anti-drop safety valves: Redundant hydraulic protection for overload scenarios.

Emergency manual descent system: Ensures operation during power outages.

Infrared obstacle sensors: Auto-stop function for collision prevention.

🔹Load-Specific Customization

Adjustable fork extensions: For irregular/long cargo (e.g., timber, steel bars).

Non-slip diamond plate platforms: Enhanced grip for oily/wet environments.

Rotating platform modules: 90°/180° pivoting for tight-space maneuvering.

🔹Environmental Adaptations

Tropical corrosion-resistant kits: Zinc-nickel plating + sealed bearings (ideal for coastal/high-humidity zones).

High-temperature hydraulic oil: Stable performance in 50°C+ environments (e.g., steel mills).

Dust-proof enclosure covers: Protects cylinders in mining/construction sites.

🔹Smart Upgrades

IoT remote monitoring: Real-time load/status alerts via mobile app.

Auto-leveling synchronization: AI-driven pressure balancing across cylinders.

Energy recovery systems: Regenerative braking reduces power consumption by 15%.

Enquire hereThis 4-cylinder/4-column lift transformed our mill’s logistics—its dual-end hydraulics handle 8-meter palm fruit bunches without sway, even in 90% humidity. The anti-corrosion coated rails survived monsoon rains, while quick-swap hydraulic modules cut maintenance from days to hours. Perfect for Southeast Asia’s harsh, high-volume industries!

The Material Handling Equipments in your industry

The Gradin goods lifts can be used to carry pallet loads of finished products or ingredients, or equipment, up and down from a mezzanine floor or second floor. The lift’s platform can be manufactured in stainless steel so it complies with regulations, is non-corrosive and can be washed.

With musculoskeletal injuries in mind, the following is a useful, but not exhaustive, list of situations that commonly arise in the manufacturing and engineering sectors during the production process:

• Repeated manipulation of the load at a distance from the trunk of the body.

• Repeated bending of the trunk to lift the load.

• A very large load that is difficult to grasp.

• Repeated handling of the load above shoulder height or at floor level.

• Lifting that involves twisting of the trunk.

• The load needs to be carried over a long distance through a cluttered or hazardous area.

When manual handling activities involve such risks of injury (particularly to the back) due to unfavourable ergonomic conditions, the basic principle is that the employer must take measures to reduce or eliminate the risk of injury.

The Gradin goods lift is designed specifically to transport standard sized pallets from manufacturing, to and from storage on a mezzanine or first floor. If a standard specification doesn’t tick all your boxes, we also specialise in bespoke configurations, working collaboratively with you to ensure your end solution is perfect for your company, employees and products.