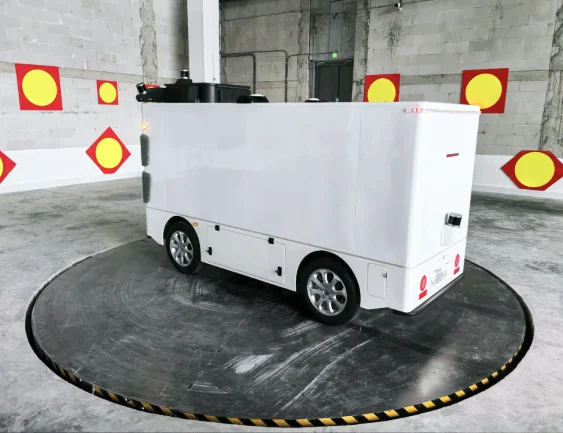

Large Rotating Platform

Gradin’s rotating platform can meet the different rotation needs of users, meet the high-precision, multi-angle rotation, realize automated high-precision rotation testing, and can be used for post-production testing. This product provides flexible customization services.

To find out more talk to our team

Adapt to high-frequency continuous operation: compact and stable structure, can adapt to high-frequency continuous operation.

PLC electronic control: PLC can accurately control the start, stop and rotation angle of the rotating platform, suitable for occasions requiring high-precision positioning.

Frequency conversion speed regulation: The smooth operation mode reduces equipment wear and extends the life of the equipment.

Ensure safe operation: high-strength thickened steel, matching a dedicated frequency conversion system, slow start and slow stop, to ensure safe and stable operation.

Efficient rotation, space saving: 360° rotation is achieved, especially suitable for places with limited space such as garages and exhibition halls.

Strong durability: Made of rust-proof and corrosion-resistant materials, suitable for various environments.

Want to know more? Our helpful

team are here to help.

Request a quote

Large Rotating Platform frequently asked questions

Three environmental adaptation packages:

- IP66 protection: Sealed bearing units with hydrophobic coatings

- Thermal package: -40°C to 120°C operational range

- Explosion-proof: ATEX-certified drive systems

Quadruple safety integration:

- Dynamic load monitoring: Real-time weight distribution analysis

- Redundant braking: Electromagnetic + mechanical disk brakes

- Emergency positioning: Laser-guided inertial shutdown

- Anti-collision system: 360° LiDAR perimeter scanning

Predictive maintenance protocol:

- Daily: Bearing temperature checks

- Weekly: Gearbox oil analysis

- Quarterly: Encoder calibration

- Annual: Structural stress testing