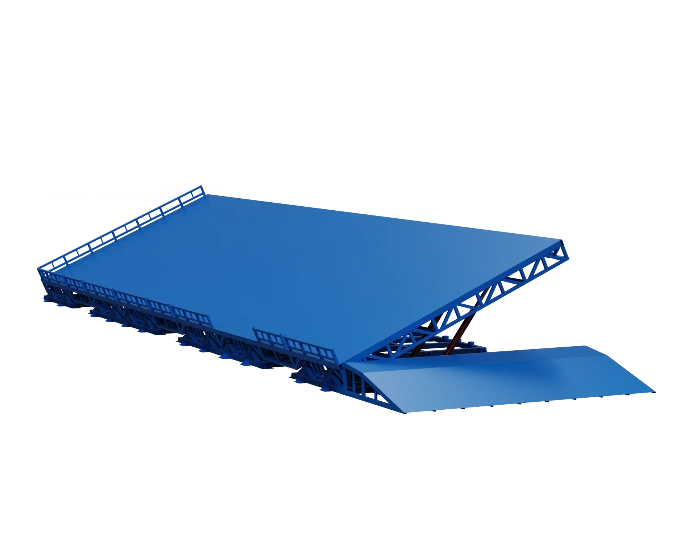

Industrial Tilter

Heavy-duty, 360° rotation, safe handling for heavy loads (up to 160 tons). Durable steel design boosts efficiency, reduces labor. Ideal for machinery, construction.

To find out more talk to our team

Our robust tilters streamline material handling with smooth 360° rotation and rapid installation, ready for operation in just eight weeks. Designed for versatility, they feature adjustable speed, multiple load capacities, and compact layouts to maximize space efficiency—ideal for workshops, assembly lines, and heavy machinery maintenance.

Gradin Industrial Tilters are engineered to handle loads up to 160 tons, crafted from reinforced steel for unmatched durability. Customizable with safety locks, ergonomic controls, and specialized clamping systems, they ensure precision in demanding applications like construction, logistics, and automotive industries. Boost productivity while cutting labor costs and operational risks.

Want to know more? Our helpful

team are here to help.

Request a quote

View our range of Industrial Tilter

Roller Diameter/Spacing: 100–300 mm / 200–500 mm

Rotation Angle: 0–180° or 360°

Rotation/Conveyor Speed: 0.5–2 RPM / 0.1–0.5 m/s

Power System: Electric (380V–480V) or Hydraulic (10–20 MPa)

Rotation Angle: 0–360° with safety stops

Rotation Speed: 0.1–0.5 RPM

Power System: High-pressure hydraulic drive (20–35 MPa)

Frame Design: Reinforced steel structure (Length: 8–15m; Width: 3–6m)

Synchronization Accuracy: ±1–5 mm (position) / ±0.5° (angle)

Rotation Speed: 0.2–1 RPM (per unit)

Power System: Hydraulic/Electric hybrid (15–30 MPa hydraulic; 380V–600V electric)

Span & Customization: 5–20m span between units (modular extensions available)

Tilt Angle: 0–120°

Tilt Speed: 0.2–1.5 RPM

Power System: Hydraulic (15–25 MPa) or Electric (380V–480V)

Base Dimensions (L×W): 3m×2m – 10m×5m

Industrial Tilter frequently asked questions

Safety is paramount. All models integrate multi-layered protection systems:

- Overload sensors to halt operation if weight exceeds capacity

- Anti-slip clamping pads with pressure feedback

- Dual emergency stop buttons (control panel + wireless remote)

- Automatic lock pins at critical angles (90°/180°)

Compliance with OSHA, CE, and ISO 12100 standards. Optional explosion-proof motors and corrosion-resistant coatings available.

Customization is our strength. We adapt:

- Dimensions: Tailor length/width/height to fit cramped workshops or oversized loads.

- Clamping mechanisms: Choose from pneumatic claws, hydraulic arms, or conveyor-integrated rollers.

- Control interfaces: Options include PLC panels, IoT-enabled remote monitoring, or voice-command systems for hands-free operation.

- Material compatibility: Add non-sparking components for flammable environments or food-grade coatings for pharmaceutical use.

Yes! Our rugged designs thrive in extreme conditions:

- Temperature resilience: Operate from -20°C to 60°C with heated/cooled hydraulic reservoirs.

- Weatherproofing: IP65-rated electronics and stainless-steel frames resist dust, moisture, and chemical splashes.

- Explosion-proofing: ATEX-certified models for oil refineries or grain silos.

- Corrosion resistance: Galvanized coatings or epoxy paint for coastal or acidic environments.