30.4.2025 / 6 minute read

Zero Leakage, Heavy Duty: Technical Breakdown of a 15-Ton Hydraulic Flipping Machine

Project Overview

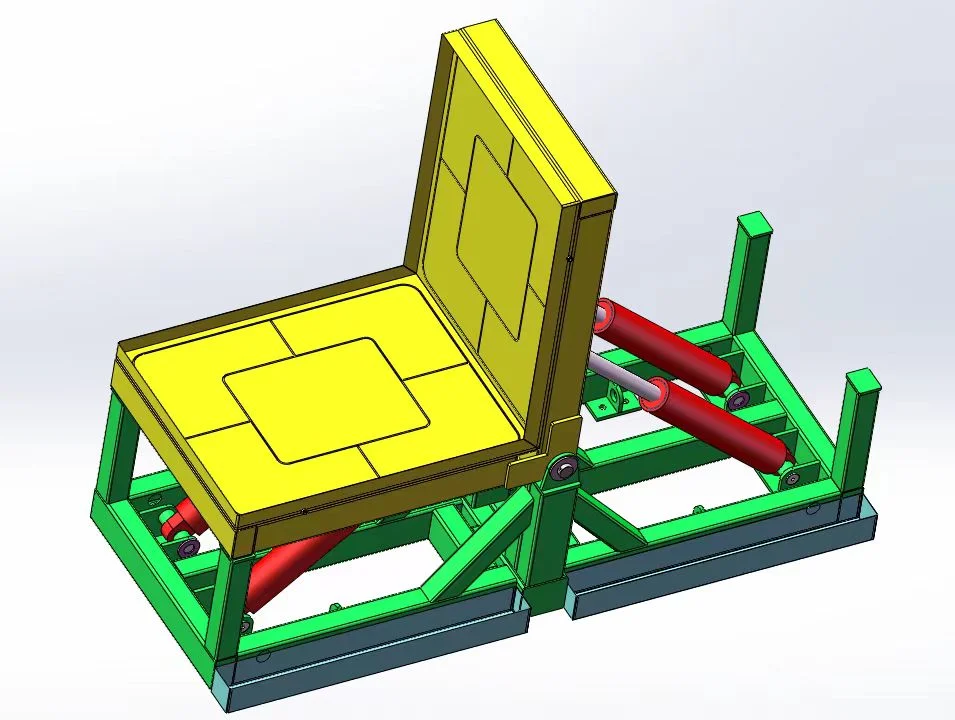

This 15-ton hydraulic flipping machine is designed for cleaning, maintaining, and repairing heavy-duty components (e.g., bearing seats).

Featuring dual 1500×2000mm platforms and 90-degree flipping, it safely handles large workpieces (up to 1500×1500×1300mm).

Integrated oil-guiding channels and collection trays enable waste oil recycling, aligning with eco-friendly production standards for heavy industries.

Basic Parameters –

| Item | Specification |

|---|---|

| Model | FZ15-90 |

| Platform Size | 1500×2000mm + 1500×2000mm |

| Flipping Angle | 90° |

| Capacity | 15 tons |

| Cycle Time | 60s per flip |

| Control | Jog Control |

| Loading | Crane-Assisted |

| Material Type | Bearing Seats |

The Challenge

- Cleaning heavy components (e.g., bearing seats) requires frequent flipping, but traditional tools are inefficient and unsafe.

- Oil leakage during cleaning risks environmental contamination, while manual collection is costly.

- Large workpieces (>1.5m³) lack stable, size-compatible flipping solutions.

Solutions

- Dual-Platform Hydraulic System: 15-ton capacity, 60s flipping cycle, bidirectional loading.

- Eco-Friendly Oil Management: Oil guide channels + collection trays improve waste oil recycling by 40%.

- Industrial Safety: Smooth hydraulic operation supports workpieces up to 1500×1500×1300mm.

Advantages

- High Efficiency: 60s flipping cycle minimizes downtime.

- Eco-Compliance: Closed-loop oil recycling reduces pollution risks.

- Heavy-Duty Capacity: Dual platforms support 15-ton loads for oversized components.

- Operational Safety: Anti-shake hydraulics + jog control prevent workpiece damage.