25.4.2025 / 4 minute read

Rotating Stage Lift Platform for Desert Music Festival

Key points –

- High Load Capacity: Capable of lifting up to 2 tons, suitable for heavy-duty applications.

- Lifting Height: Maximum lifting height of 2.5 meters, allowing for significant vertical movement.

- Large Platform Diameter: 5-meter diameter platform provides ample space for various applications.

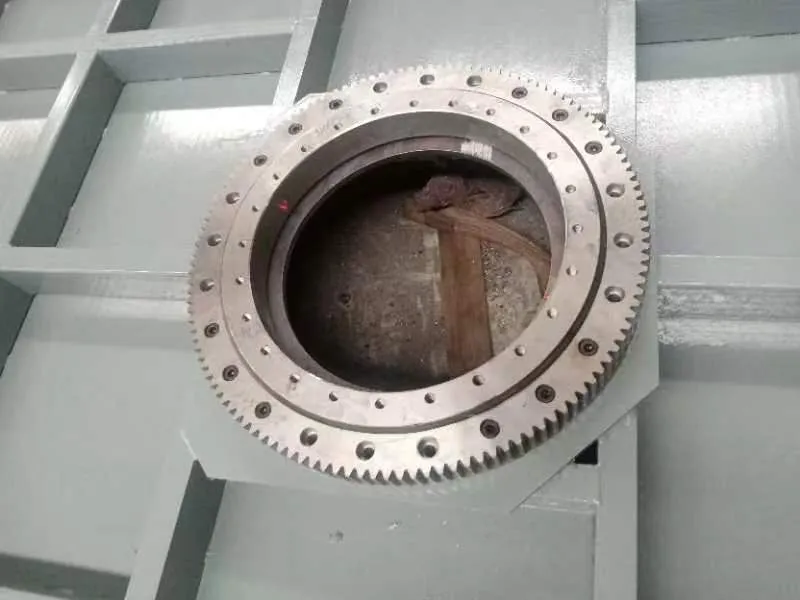

- 360-Degree Rotation: Enables full rotational movement, enhancing flexibility in positioning and operations.

- Robust Construction: Built with durable materials to ensure long-term reliability and stability.

- Smooth Operation: Designed for smooth lifting and rotation, minimizing vibrations and ensuring safety.

- Safety Features: Equipped with safety mechanisms to prevent accidents during operation.

- Ease of Use: User-friendly controls for convenient operation and precise positioning.

- Maintenance-Friendly: Easy to maintain with accessible components and a straightforward design.

How is the Rotating Stage Lift Platform used?

Designed for the desert spectacle, this hydraulically driven rotating stage elevates performers seamlessly above the sands.

Its 360° rotation creates a captivating visual experience, enhancing the performance with dynamic lighting that shifts and changes, mirroring the colors of the desert landscape.

The lift height (3m) allows singers to “rise” against the backdrop of the starry sky, merging technology with the surreal beauty of the surrounding dunes and cosmos.

The Challenge

Harsh Desert Environment

Sand Infiltration: Fine sand from the desert can damage mechanical components and reduce system lifespan.

Temperature Extremes: Diurnal temperature fluctuations (-10°C to 40°C) strain hydraulic and electrical systems.

Ecological Preservation: Strict requirements to avoid damage to the fragile desert ecosystem during installation.

Unstable Terrain

Soft Sand Foundation: Traditional anchoring systems fail to stabilize the stage on shifting sand.

Wind Loads: Strong desert winds (up to 20 m/s) risk destabilizing elevated structures.

Large-Scale Audience Safety

Crowd Proximity: 10,000+ spectators near the stage demand fail-safe safety mechanisms.

Emergency Evacuation: Rapid lowering of the stage during emergencies (e.g., sudden sandstorms).

Aesthetic Integration

Natural Landscape Harmony: The stage must blend with the desert scenery while delivering dramatic visual effects.

Solutions

Environmental Adaptability

Sealed Hydraulic System: IP67-rated components with sand-resistant coatings to prevent grit ingress.

Temperature-Tolerant Materials: Hydraulic oil rated for -30°C to 60°C and stainless steel bearings.

Eco-Friendly Installation: Modular base plates (no concrete pouring) to protect the desert floor.

Stability in Shifting Sand

Geotextile-Reinforced Foundation: Layered geotextile mats and weighted ballast blocks for load distribution.

Wind-Resistant Design: Aerodynamic platform shape and real-time wind speed monitoring with auto-lockdown (≥15 m/s).

Safety & Reliability

Dual Hydraulic Locks: Redundant braking systems to prevent accidental drops.

Emergency Power Backup: Solar-battery hybrid system for uninterrupted operation during grid failures.

Aesthetic & Functional Balance

Camouflage Design: Sand-colored platform surface and retractable LED panels mimicking starry skies.

360° Silent Rotation: Low-noise gearless motors for smooth, silent movement during performances.

Advantages

Unmatched Reliability

Operates flawlessly in extreme desert conditions with zero downtime during the concert.

Safety First

Real-time stability alerts and emergency protocols ensure performer and audience safety.

Eco-Conscious Engineering

Minimal environmental footprint with reusable modular components and solar power integration.

Immersive Visual Impact

Dynamic elevation (0–8m) and rotation synchronized with lighting/audio for a “floating stage” illusion.

Global Standards Compliance

CE, ISO 12100 (safety of machinery), and IEC 60529 (ingress protection) certifications.

Gallery